Introduction to Solder Stencils

Solder stencils are an essential tool in the world of electronics manufacturing, particularly in surface mount technology (SMT). These thin metal sheets, typically made from stainless steel or nickel, feature precise cut-outs that correspond to the pads on a printed circuit board (PCB). The stencil is used to apply solder paste onto the PCB, ensuring that the correct amount of paste is deposited in the right locations. This process is crucial for achieving reliable and consistent solder joints during the reflow soldering process.

Benefits of Using Solder Stencils

Using solder stencils offers several advantages over other methods of applying solder paste, such as manual dispensing or screen printing:

-

Precision: Solder stencils allow for highly accurate and consistent solder paste deposition, ensuring that the correct amount of paste is applied to each pad on the PCB.

-

Efficiency: Stencils enable the rapid application of solder paste to multiple PCBs, significantly reducing the time and labor required compared to manual methods.

-

Cost-effectiveness: By minimizing solder paste waste and reducing the need for rework due to insufficient or excessive solder, stencils help to lower overall production costs.

-

Repeatability: Solder stencils ensure that the solder paste application process is repeatable and consistent across multiple production runs, leading to higher quality and reliability of the finished product.

Types of Solder Stencils

There are two main types of solder stencils: framed and frameless.

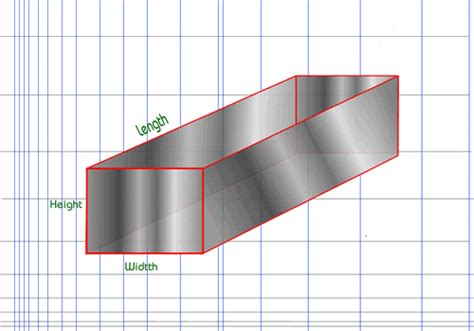

Framed Solder Stencils

Framed solder stencils consist of a thin metal sheet (usually stainless steel or nickel) that is mounted on a rigid aluminum frame. The frame provides stability and makes handling the stencil easier during the solder paste application process. Framed stencils are more durable and less prone to damage compared to frameless stencils, making them suitable for high-volume production runs.

Frameless Solder Stencils

Frameless solder stencils, also known as prototype stencils or quick-turn stencils, are simply the metal sheet without the surrounding frame. These stencils are more flexible and can be easily cut to size, making them ideal for prototyping and low-volume production. However, frameless stencils are more susceptible to damage and may require more careful handling during use.

Solder Stencil Materials

Solder stencils are typically made from one of two materials: stainless steel or nickel.

Stainless Steel Stencils

Stainless steel is the most common material used for solder stencils due to its durability, stability, and cost-effectiveness. Stainless steel stencils are available in various thicknesses, typically ranging from 0.1 mm to 0.2 mm (4 to 8 mils), depending on the application requirements.

Nickel Stencils

Nickel stencils are growing in popularity due to their superior durability and resistance to wear compared to stainless steel. Nickel’s inherent properties allow for the creation of finer apertures and more intricate designs, making them suitable for applications involving smaller components and tighter pitches. However, nickel stencils are generally more expensive than their stainless steel counterparts.

Solder Stencil Thicknesses

Choosing the appropriate solder stencil thickness is crucial for achieving optimal solder paste deposition and ensuring reliable solder joints. The stencil thickness determines the volume of solder paste applied to each pad on the PCB. Some common stencil thicknesses and their applications are listed in the table below:

| Stencil Thickness | Imperial (mils) | Metric (mm) | Application |

|---|---|---|---|

| Fine Pitch | 3-4 | 0.075-0.1 | Chip components, 0201, 0402 |

| Standard | 5-6 | 0.125-0.15 | Most SMT components, 0603, 0805, SOICs |

| Heavy Deposit | 7-8 | 0.175-0.2 | Connectors, through-hole components |

| Extra Heavy | 10+ | 0.25+ | Power components, large connectors |

It’s essential to consult with your PCB Assembly partner or stencil manufacturer to determine the optimal stencil thickness for your specific application, taking into account factors such as component sizes, pitches, and solder paste properties.

Solder Stencil Aperture Design

The aperture design of a solder stencil refers to the size, shape, and layout of the openings that allow solder paste to be deposited onto the PCB pads. Proper aperture design is critical for ensuring the correct amount of solder paste is applied and for achieving reliable solder joints.

Aperture Size

Aperture size is typically expressed as a percentage of the pad size on the PCB. For example, a 1:1 ratio means that the aperture size is equal to the pad size. In general, smaller components and finer pitches require smaller apertures to prevent solder bridging, while larger components and coarser pitches can accommodate larger apertures for increased solder paste deposition.

Aperture Shape

The most common aperture shapes are square and rectangular, which are suitable for most SMT components. However, some components, such as QFNs (Quad Flat No-leads) and BGAs (Ball Grid Arrays), may require specialized aperture shapes to ensure proper solder paste deposition and prevent solder beading or insufficiency.

Aperture Layout

The aperture layout should be designed to match the pad layout on the PCB, taking into account factors such as component orientation, pitch, and any required adjustments for solder paste release. It’s essential to work closely with your PCB design team and stencil manufacturer to ensure that the aperture layout is optimized for your specific application.

Solder Stencil Fabrication Methods

There are several methods for fabricating solder stencils, each with its own advantages and limitations.

Laser Cutting

Laser cutting is the most common method for fabricating solder stencils. This process uses a high-powered laser to precisely cut the apertures into the metal sheet. Laser cutting offers several advantages, including high precision, rapid turnaround times, and the ability to create complex aperture shapes. However, laser-cut stencils may have slightly rougher aperture edges compared to other methods.

Chemical Etching

Chemical etching involves using a chemical solution to dissolve the metal in the areas where the apertures should be, leaving the desired pattern behind. This method can produce very smooth aperture edges and is suitable for creating fine details. However, chemical etching is generally slower and more expensive than laser cutting.

Electroforming

Electroforming is a process that uses electroplating to build up the stencil material around a patterned mandrel. This method can produce stencils with very smooth aperture walls and tight tolerances, making it suitable for applications with extremely fine pitches or complex designs. However, electroforming is the most expensive and time-consuming stencil fabrication method.

Solder Stencil Maintenance and Cleaning

Proper maintenance and cleaning of solder stencils are essential for ensuring consistent solder paste deposition and extending the life of the stencil.

Cleaning Frequency

The frequency of stencil cleaning depends on various factors, such as the type of solder paste used, the volume of production, and the environment in which the stencil is being used. As a general rule, stencils should be cleaned every 4-8 hours of continuous use or between production shifts.

Cleaning Methods

There are two primary methods for cleaning solder stencils: manual and automated.

-

Manual Cleaning: Manual cleaning involves using solvents and wipers to remove solder paste residue from the stencil. This method is suitable for low-volume production or when an automated cleaning system is not available. However, manual cleaning is time-consuming and may not be as thorough as automated methods.

-

Automated Cleaning: Automated stencil cleaning systems use a combination of solvents, brushes, and high-pressure sprays to remove solder paste residue from the stencil. These systems are more efficient and consistent than manual cleaning, making them ideal for high-volume production. Automated cleaning systems can also help to extend the life of the stencil by minimizing the risk of damage during the cleaning process.

Stencil Storage

When not in use, solder stencils should be stored in a clean, dry environment to prevent damage and contamination. Stencils should be stored vertically to minimize the risk of warping or bending, and they should be protected from dust and debris using covers or storage containers.

Troubleshooting Common Solder Stencil Issues

Despite careful design and maintenance, solder stencils can sometimes experience issues that affect the quality of solder paste deposition. Some common problems and their solutions are listed below:

-

Solder Bridging: Solder bridging occurs when solder paste deposits merge together, creating an unintended connection between pads. This can be caused by excessive solder paste deposition, improper aperture design, or stencil damage. To resolve this issue, consider reducing the stencil thickness, adjusting the aperture size or shape, or replacing a damaged stencil.

-

Insufficient Solder Paste: Insufficient solder paste deposition can lead to weak or open solder joints. This can be caused by clogged apertures, improper aperture design, or a worn-out stencil. To resolve this issue, clean the stencil thoroughly, adjust the aperture design, or replace the stencil if it is worn or damaged.

-

Solder Beading: Solder beading occurs when solder paste deposits form rounded, ball-like shapes instead of properly wetting the pads. This can be caused by improper aperture design, solder paste formulation issues, or incorrect stencil-to-PCB gap settings. To resolve this issue, adjust the aperture design, consult with your solder paste supplier, or check and adjust the stencil-to-PCB gap.

-

Stencil Warping: Stencil warping can occur due to improper handling, storage, or cleaning processes. Warped stencils can lead to inconsistent solder paste deposition and poor print quality. To prevent stencil warping, handle stencils carefully, store them vertically in a protected environment, and follow proper cleaning procedures.

Frequently Asked Questions (FAQ)

-

What is the difference between a solder paste stencil and a solder mask?

A solder paste stencil is a thin metal sheet with cut-outs that correspond to the pads on a PCB, used for applying solder paste. A solder mask, on the other hand, is a layer applied to the PCB itself that covers the non-solderable areas, preventing solder from adhering to those areas during the soldering process. -

Can solder stencils be reused?

Yes, solder stencils can be reused multiple times with proper cleaning and maintenance. The lifespan of a stencil depends on factors such as the material, thickness, and the frequency of use and cleaning. -

How do I choose the right solder stencil thickness for my application?

The appropriate solder stencil thickness depends on factors such as component sizes, pitches, and the desired solder paste volume. Consult with your PCB assembly partner or stencil manufacturer to determine the optimal thickness for your specific application. -

What is the typical lifespan of a solder stencil?

The lifespan of a solder stencil can vary depending on the material, thickness, and usage conditions. On average, a well-maintained stencil can last for 20,000 to 50,000 prints before needing replacement. -

Can solder stencils be customized for specific applications?

Yes, solder stencils can be customized to suit specific applications. Customization options include aperture sizes, shapes, and layouts, as well as stencil thickness and material. Work closely with your stencil manufacturer to design a stencil that meets your unique requirements.

Conclusion

Solder paste stencils play a crucial role in the SMT Assembly process, ensuring accurate and consistent solder paste deposition for reliable solder joints. By understanding the types, materials, thicknesses, and aperture designs of solder stencils, as well as proper maintenance and troubleshooting techniques, you can optimize your SMT assembly process and achieve higher quality and reliability in your electronic products. Consult with your PCB assembly partner and stencil manufacturer to select the best solder stencil solution for your specific application, and always prioritize proper handling, cleaning, and storage to maximize the lifespan and performance of your solder stencils.

No responses yet