Introduction to PCB Drilled Holes

Printed Circuit Boards (PCBs) are essential components in modern electronic devices. They provide a platform for mounting and interconnecting various electronic components. One crucial aspect of PCB design and manufacturing is the creation of drilled holes. These holes serve multiple purposes, such as allowing component leads to pass through, enabling inter-layer connections, and facilitating mounting of the PCB. In this comprehensive article, we will dive deep into the world of PCB drilled holes, covering everything you need to know to avoid surprises during the design and manufacturing process.

Types of PCB Drilled Holes

There are several types of drilled holes used in PCBs, each serving a specific purpose. Let’s explore the most common types:

Through Holes

Through holes are the most basic type of drilled holes in PCBs. They extend completely through the board, allowing component leads to pass through and be soldered on the opposite side. Through holes are typically used for mounting through-hole components such as resistors, capacitors, and connectors.

Blind Vias

Blind vias are drilled holes that start from one surface of the PCB and terminate at a specific inner layer without reaching the opposite surface. They are commonly used to establish connections between the outer layers and inner layers of the PCB, facilitating more compact designs and reducing the overall size of the board.

Buried Vias

Buried vias are drilled holes that connect two or more inner layers of the PCB without extending to either surface. They are used to create interconnections between inner layers, allowing for more complex routing and higher density designs. Buried vias are typically used in multi-layer PCBs.

Micro Vias

Micro vias are small-diameter drilled holes that are used for high-density interconnects in advanced PCB designs. They are typically laser-drilled and have diameters smaller than 0.15mm. Micro vias enable the creation of fine-pitch components and help in reducing the overall size of the PCB.

Drill Hole Sizes and Tolerances

When designing PCBs, it is crucial to specify the correct drill hole sizes and tolerances to ensure proper fitment and functionality of the components. Here are some key considerations:

Drill Bit Sizes

PCB drilled holes are created using drill bits of specific sizes. The most common drill bit sizes range from 0.2mm to 6.35mm in diameter. It is important to select the appropriate drill bit size based on the component requirements and the PCB manufacturing capabilities.

Hole Diameter Tolerances

Hole diameter tolerances specify the acceptable range of variation in the drilled hole size. The tolerance is typically expressed as a plus/minus value. For example, a hole with a nominal diameter of 1.0mm and a tolerance of ±0.05mm means that the actual hole diameter can vary between 0.95mm and 1.05mm. Tighter tolerances may be required for critical components or high-precision applications.

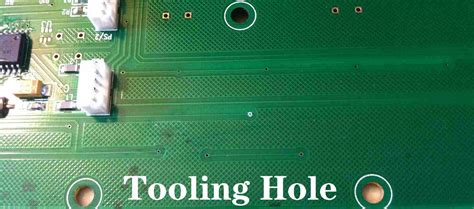

Plated vs. Non-Plated Holes

Drilled holes in PCBs can be either plated or non-plated. Plated holes have a conductive layer of copper deposited on the inside walls of the hole, allowing for electrical connectivity between layers. Non-plated holes, also known as mechanical holes, do not have a conductive coating and are used for mounting purposes or as guide holes.

Here’s a table summarizing the common drill bit sizes and their typical applications:

| Drill Bit Size (mm) | Typical Application |

|---|---|

| 0.2 – 0.5 | Micro vias, fine-pitch components |

| 0.6 – 1.0 | Standard through-hole components |

| 1.1 – 2.0 | Connectors, larger components |

| 2.1 – 6.35 | Mounting holes, power connectors |

PCB Drilling Process

The PCB drilling process involves several steps to ensure accurate and reliable hole creation. Let’s take a closer look at each step:

Drill File Generation

The first step in the PCB drilling process is the generation of a drill file. The drill file contains information about the location, size, and type of each drilled hole on the PCB. It is typically generated using PCB design software and is used to guide the drilling machine.

Drilling Machine Setup

Once the drill file is ready, the drilling machine is set up with the appropriate drill bits and parameters. The drill bits are loaded into the machine’s spindles, and the drilling speed, feed rate, and depth are adjusted based on the material and thickness of the PCB.

Drilling Operation

During the drilling operation, the PCB is securely fixed on the drilling machine’s table. The machine then starts drilling the holes according to the drill file. The drilling process is usually automated, with the machine moving the drill bits to the specified locations and creating the holes at the programmed depths.

Deburring and Cleaning

After the drilling operation, the PCB undergoes a deburring and cleaning process. Deburring involves removing any rough edges or burrs around the drilled holes to ensure a smooth surface. Cleaning helps remove any debris or dust generated during the drilling process, preparing the PCB for the next manufacturing steps.

Design Considerations for PCB Drilled Holes

When designing PCBs with drilled holes, there are several important considerations to keep in mind to ensure manufacturability, reliability, and functionality. Here are some key points to consider:

Hole Placement and Spacing

Proper placement and spacing of drilled holes are essential to avoid manufacturing issues and ensure the integrity of the PCB. Consider the following guidelines:

– Maintain sufficient spacing between holes to prevent mechanical stress and ensure proper copper ring around the holes.

– Follow the manufacturer’s recommendations for minimum hole-to-hole and hole-to-edge spacing based on the PCB Thickness and material.

– Avoid placing holes too close to the edge of the PCB to prevent breakage during the drilling process.

Pad Size and Annular Ring

The pad size and annular ring around the drilled holes play a crucial role in ensuring reliable soldering and preventing issues such as breakout or disconnection. Consider the following:

– The pad size should be large enough to accommodate the component lead and provide sufficient area for soldering.

– The annular ring, which is the copper area around the hole, should be wide enough to maintain electrical connectivity and mechanical strength.

– Follow the manufacturer’s guidelines for minimum annular ring width based on the hole size and PCB thickness.

Drill Hole Aspect Ratio

The drill hole aspect ratio is the ratio of the hole depth to its diameter. It is an important consideration, especially for high-aspect-ratio holes. Consider the following:

– High-aspect-ratio holes (greater than 8:1) may require specialized drilling techniques and equipment.

– Ensure that the aspect ratio is within the manufacturing capabilities of the PCB fabricator to avoid drilling-related issues.

Plating Thickness

The plating thickness of the drilled holes is critical for ensuring reliable electrical connectivity and mechanical strength. Consider the following:

– Specify the appropriate plating thickness based on the hole size and the required current-carrying capacity.

– Thicker plating may be necessary for high-current applications or to meet specific industry standards.

– Consult with the PCB manufacturer to determine the optimal plating thickness for your specific requirements.

Common Issues and Troubleshooting

Despite careful design and manufacturing, issues related to PCB drilled holes can still occur. Here are some common problems and troubleshooting tips:

Hole Misalignment

Hole misalignment occurs when the drilled holes do not align properly with the pads or component leads. This can lead to soldering difficulties and compromised electrical connections. To troubleshoot hole misalignment:

– Double-check the drill file and ensure that the hole locations and sizes are accurate.

– Verify that the drilling machine is properly calibrated and aligned.

– Consider adjusting the pad size or shape to accommodate minor misalignments.

Incomplete or Blocked Holes

Incomplete or blocked holes can occur due to various reasons, such as drill bit breakage, debris accumulation, or insufficient drilling depth. To troubleshoot incomplete or blocked holes:

– Inspect the drill bits for wear or damage and replace them if necessary.

– Ensure that the drilling depth is set correctly and the drill bits are reaching the desired depth.

– Clean the holes using compressed air or a specialized cleaning solution to remove any debris or blockages.

Plating Issues

Plating issues, such as voids, thin spots, or poor adhesion, can compromise the electrical and mechanical integrity of the drilled holes. To troubleshoot plating issues:

– Verify that the plating process parameters, such as current density and plating time, are within the specified range.

– Ensure that the PCB surface is properly cleaned and prepared before the plating process.

– Consider using a higher-quality plating solution or adjusting the plating conditions to improve the plating quality.

Best Practices for PCB Drilled Holes

To ensure the best results and minimize issues related to PCB drilled holes, follow these best practices:

- Collaborate closely with the PCB manufacturer during the design phase to ensure that your requirements are feasible and can be efficiently manufactured.

- Use standard drill bit sizes whenever possible to reduce manufacturing costs and lead times.

- Specify the appropriate tolerances for critical holes and communicate them clearly to the manufacturer.

- Follow the manufacturer’s guidelines for minimum hole-to-hole and hole-to-edge spacing to ensure the mechanical integrity of the PCB.

- Use plated holes for electrical connectivity and non-plated holes for mechanical purposes to optimize the manufacturing process.

- Consider the aspect ratio of the drilled holes and ensure that it is within the manufacturing capabilities of the PCB fabricator.

- Specify the appropriate plating thickness based on the electrical and mechanical requirements of the PCB.

- Perform thorough testing and inspection of the drilled holes during the manufacturing process to catch any issues early on.

- Maintain clear and comprehensive documentation, including the drill file and manufacturing specifications, to avoid confusion and ensure consistent results.

Frequently Asked Questions (FAQ)

- What is the minimum hole size that can be drilled in a PCB?

-

The minimum hole size depends on the PCB thickness and the manufacturing capabilities of the PCB fabricator. Typically, holes as small as 0.2mm in diameter can be drilled in standard PCBs. For smaller holes, such as micro vias, advanced drilling techniques like laser drilling may be required.

-

Can I use the same drill bit size for all the holes in my PCB design?

-

While using the same drill bit size for all holes can simplify the manufacturing process, it may not always be practical or optimal. Different components may require different hole sizes based on their lead diameters. It is recommended to use standard drill bit sizes that accommodate the specific requirements of each component.

-

What is the purpose of plated holes in PCBs?

-

Plated holes in PCBs serve the purpose of creating electrical connectivity between layers. The conductive plating on the inside walls of the holes allows signals and current to flow between the different layers of the PCB. Plated holes are essential for establishing interconnections in multi-layer PCBs.

-

How do I specify the tolerance for drilled holes in my PCB design?

-

To specify the tolerance for drilled holes, you need to provide the nominal hole diameter along with the acceptable deviation. For example, a hole size of 1.0mm with a tolerance of ±0.05mm would be specified as “1.0mm ±0.05mm.” It is important to communicate the tolerance requirements clearly to the PCB manufacturer to ensure that the holes are drilled within the acceptable range.

-

What are the consequences of not following the recommended hole-to-hole and hole-to-edge spacing guidelines?

- Not following the recommended hole-to-hole and hole-to-edge spacing guidelines can lead to several issues. Insufficient spacing between holes can cause mechanical stress and weaken the structural integrity of the PCB. Holes placed too close to the edge of the board may result in breakage or damage during the drilling process. Violating these guidelines can also affect the reliability and durability of the PCB in the long run.

Conclusion

PCB drilled holes are a critical aspect of PCB design and manufacturing. Understanding the types of drilled holes, their sizes and tolerances, and the drilling process itself is essential for creating reliable and functional PCBs. By considering factors such as hole placement, pad size, aspect ratio, and plating thickness, designers can ensure that their PCBs meet the required specifications and perform optimally.

Troubleshooting common issues related to PCB drilled holes requires a systematic approach and attention to detail. Following best practices and collaborating closely with the PCB manufacturer can help minimize issues and ensure a smooth manufacturing process.

By staying informed about the intricacies of PCB drilled holes and applying the knowledge gained from this article, you can confidently design and manufacture PCBs that meet your specific requirements while avoiding costly surprises along the way.

No responses yet