What are PCBs and Why are They Important in Robotics?

PCBs are thin, flat boards made of insulating materials, such as fiberglass or plastic, with conductive copper traces etched onto their surface. These traces form a network of electrical connections that allow components, such as microcontrollers, sensors, and actuators, to communicate and function together seamlessly.

In robotics, PCBs serve as the central nervous system, connecting and coordinating the various subsystems that make up a robot. They enable the robot to process sensory input, execute control algorithms, and drive actuators to perform desired actions. Without PCBs, robots would be a collection of disparate components unable to work together effectively.

The Advantages of Using PCBs in Robotics

- Miniaturization: PCBs allow for the compact integration of numerous components, reducing the overall size and weight of the robot.

- Reliability: Well-designed PCBs ensure stable electrical connections and minimize the risk of short circuits or component failures.

- Customization: PCBs can be tailored to meet the specific requirements of a robot, accommodating unique component layouts and functionalities.

- Scalability: PCBs enable the creation of modular designs, allowing for easy expansion or modification of the robot’s capabilities.

Designing PCBs for Robots

The process of designing PCBs for robots involves several key considerations to ensure optimal performance and reliability. Some of these factors include:

1. Component Selection

Choosing the right components is crucial in PCB design for robots. Designers must consider factors such as power requirements, operating conditions, and compatibility with other components. Key components in robotic PCBs include:

- Microcontrollers: The “brain” of the robot, responsible for processing data and executing control algorithms.

- Sensors: Devices that gather information about the robot’s environment or internal states, such as accelerometers, gyroscopes, and encoders.

- Actuators: Components that enable the robot to move or manipulate objects, such as motors, servos, and pneumatic systems.

- Power management: Circuits that regulate and distribute power to the various components on the PCB.

2. Schematic Design

The schematic design is a graphical representation of the electrical connections between components on the PCB. Designers use software tools, such as Eagle or KiCad, to create schematics that define the logical layout of the PCB.

A well-designed schematic should:

– Ensure proper connectivity between components

– Minimize signal interference and crosstalk

– Incorporate appropriate power management and filtering

– Include necessary protection circuits, such as fuses and Voltage Regulators

3. Layout Design

Once the schematic is finalized, designers move on to the layout design, which involves the physical placement and routing of components on the PCB. The layout design is critical for several reasons:

- Proper component placement: Components must be arranged in a way that minimizes signal interference, thermal issues, and physical constraints.

- Trace routing: Copper traces must be routed efficiently to minimize signal loss and ensure proper signal integrity.

- Electromagnetic compatibility (EMC): The layout must be designed to minimize electromagnetic interference (EMI) and ensure compliance with EMC standards.

4. Design for Manufacturing (DFM)

To ensure that the PCB can be manufactured reliably and cost-effectively, designers must adhere to DFM guidelines. These guidelines include:

- Minimum trace width and spacing

- Minimum hole sizes for through-hole components

- Clearance and creepage distances

- Solder mask and silkscreen requirements

By following DFM guidelines, designers can minimize manufacturing issues and improve the overall quality of the PCB.

Manufacturing PCBs for Robots

Once the PCB design is complete, it moves on to the manufacturing stage. PCB manufacturing involves several key processes:

1. PCB Fabrication

PCB fabrication begins with the creation of a copper-clad laminate, which is a sheet of insulating material (such as fiberglass) with a thin layer of copper bonded to one or both sides. The copper is then selectively removed through a process called etching, leaving behind the desired traces and pads.

Multi-layer PCBs are fabricated by stacking and bonding several single-layer PCBs together, with insulating layers between them. Holes are drilled through the layers to allow for electrical connections between them, a process known as via formation.

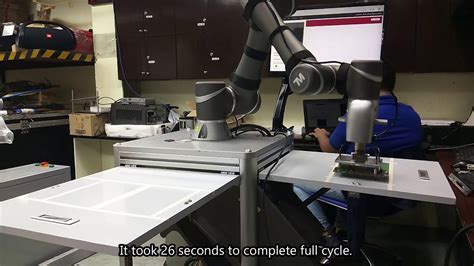

2. PCB Assembly

After the PCB is fabricated, components are mounted onto the board through a process called PCB assembly. There are two main methods of PCB assembly:

- Through-hole assembly: Components with long leads are inserted through holes in the PCB and soldered onto the opposite side.

- Surface-mount assembly: Components are placed directly onto pads on the surface of the PCB and soldered in place.

Modern PCB assembly often involves the use of automated pick-and-place machines, which can rapidly and precisely place components onto the board. The board then undergoes a soldering process, typically using reflow ovens or wave soldering machines.

3. PCB Testing and Inspection

After assembly, PCBs undergo rigorous testing and inspection to ensure proper functionality and quality. Some common testing methods include:

- In-circuit testing (ICT): Probes are used to test individual components and their connections on the PCB.

- Functional testing: The PCB is powered up and tested as a complete system to verify its overall functionality.

- Boundary scan testing: A specialized test method that uses built-in test circuitry to test the interconnections between components on the PCB.

Visual inspection is also performed to check for any manufacturing defects, such as solder bridges, component misalignment, or damaged components.

The Impact of PCBs on Robot Capabilities

Advancements in PCB technology have had a profound impact on the capabilities of modern robots. Some of the key areas where PCBs have enabled significant progress include:

1. Autonomous Navigation

PCBs equipped with powerful microcontrollers and a variety of sensors, such as cameras, LiDAR, and IMUs, allow robots to perceive and navigate their environment autonomously. Advanced algorithms run on these PCBs, enabling robots to map their surroundings, plan paths, and avoid obstacles.

2. Dexterous Manipulation

High-density PCBs with advanced motor control circuits enable robots to perform precise and dexterous manipulation tasks. By integrating sensors, such as force/torque sensors and tactile sensors, robots can adapt to different objects and environments, allowing for more flexible and intelligent manipulation.

3. Wireless Communication

PCBs with integrated wireless modules, such as Wi-Fi, Bluetooth, or cellular connectivity, allow robots to communicate with other devices and systems, enabling remote monitoring, control, and data exchange. This wireless connectivity is essential for applications such as collaborative robotics, where multiple robots work together to accomplish tasks.

4. Machine Learning and Artificial Intelligence

Advanced PCBs with high-performance processors and ample memory resources enable robots to run sophisticated machine learning and AI algorithms. These algorithms allow robots to learn from their experiences, adapt to new situations, and make intelligent decisions based on the data they collect.

Challenges and Future Developments

Despite the significant advancements in PCB technology for robotics, there are still several challenges and opportunities for future development:

1. Miniaturization and Integration

As robots become more compact and sophisticated, there is a growing need for smaller, more integrated PCBs. Technologies such as system-on-chip (SoC) and package-on-package (PoP) are enabling the development of highly miniaturized and integrated PCBs that can fit into the limited space available in small robots.

2. Flexibility and Stretchability

Traditional rigid PCBs can limit the flexibility and adaptability of robots, particularly in applications where conformity to irregular surfaces or structures is required. The development of flexible and stretchable PCBs, using materials such as polyimide or elastomeric substrates, is opening up new possibilities for robots that can bend, twist, and adapt to their environment.

3. Energy Efficiency

As robots become more autonomous and are deployed in remote or inaccessible locations, energy efficiency becomes a critical concern. PCB designers are exploring new techniques for power management, such as energy harvesting, Wireless Power Transfer, and low-power design methodologies, to extend the operating life of robots and reduce their reliance on external power sources.

4. Advanced Manufacturing Techniques

New manufacturing techniques, such as 3D printing and additive manufacturing, are enabling the creation of more complex and customized PCBs for robots. These techniques allow for the integration of multiple materials, embedded components, and unique geometries that can enhance the functionality and performance of robotic systems.

FAQs

- What is the difference between a single-layer and multi-layer PCB in robotics?

-

Single-layer PCBs have conductive traces on only one side of the board, while multi-layer PCBs have traces on multiple layers, separated by insulating layers. Multi-layer PCBs offer higher component density, better signal integrity, and improved EMI performance, making them more suitable for complex robotic systems.

-

How do PCBs enable autonomous navigation in robots?

-

PCBs designed for autonomous navigation typically integrate a variety of sensors, such as cameras, LiDAR, and inertial measurement units (IMUs), along with powerful microcontrollers or processors. These components work together to gather and process data about the robot’s environment, allowing it to localize itself, detect obstacles, and plan safe paths.

-

What are some common challenges in PCB design for robotics?

-

Some common challenges include miniaturization, signal integrity, power management, and thermal management. Designers must balance the need for high-density component placement with the requirements for proper signal routing, power distribution, and heat dissipation. Additionally, ensuring the PCB’s reliability and durability in various operating conditions is crucial.

-

How do flexible and stretchable PCBs benefit robotic applications?

-

Flexible and stretchable PCBs allow robots to conform to irregular surfaces, bend, and twist without damaging the electronic components. This is particularly useful in applications such as soft robotics, wearable devices, and robots that need to adapt to their environment. These PCBs enable the creation of more adaptable and resilient robotic systems.

-

What role do PCBs play in enabling machine learning and AI in robots?

- PCBs designed for machine learning and AI applications typically feature high-performance processors, ample memory resources, and interfaces for sensors and actuators. These components work together to enable the robot to gather and process large amounts of data, run complex algorithms, and make intelligent decisions based on that data. The PCB acts as the central hub for the robot’s learning and decision-making capabilities.

Conclusion

PCBs are the unsung heroes of the robotic world, providing the essential foundation for the complex electronic systems that bring robots to life. From autonomous navigation to dexterous manipulation, PCBs enable robots to perceive, process, and interact with their environment in increasingly sophisticated ways.

As PCB technology continues to evolve, with advancements in miniaturization, flexibility, and energy efficiency, we can expect to see even more capable and adaptable robots in the future. The symbiotic relationship between PCBs and robotics will undoubtedly play a crucial role in shaping the future of automation, manufacturing, and countless other industries.

By understanding the importance of PCBs in robotics and staying up-to-date with the latest developments in this field, engineers, researchers, and enthusiasts can contribute to the ongoing evolution of robotic technology and help push the boundaries of what is possible with these remarkable machines.

| Component | Function |

|---|---|

| Microcontroller | The “brain” of the robot, responsible for processing data and executing control algorithms |

| Sensors | Devices that gather information about the robot’s environment or internal states |

| Actuators | Components that enable the robot to move or manipulate objects |

| Power Management | Circuits that regulate and distribute power to the various components on the PCB |

Table 1: Key components in robotic PCBs and their functions.

| PCB Manufacturing Process | Description |

|---|---|

| PCB Fabrication | Creation of the physical PCB structure through processes such as etching and via formation |

| PCB Assembly | Mounting of components onto the PCB through methods like through-hole or surface-mount assembly |

| PCB Testing and Inspection | Verification of proper functionality and quality through tests such as ICT, functional testing, and visual inspection |

Table 2: PCB manufacturing processes and their descriptions.

| PCB Technology Advancement | Impact on Robot Capabilities |

|---|---|

| Miniaturization and Integration | Enables the development of compact, sophisticated robots with limited space |

| Flexibility and Stretchability | Allows robots to conform to irregular surfaces and adapt to their environment |

| Energy Efficiency | Extends the operating life of robots and reduces reliance on external power sources |

| Advanced Manufacturing Techniques | Enables the creation of complex, customized PCBs with enhanced functionality |

Table 3: PCB technology advancements and their impact on robot capabilities.

No responses yet