Introduction to Rayming-reflow-pilot

Rayming-reflow-pilot is a state-of-the-art technology used in the manufacturing process of electronic components. It is a system that enables the precise control of the reflow soldering process, ensuring high-quality and reliable solder joints. The Rayming-reflow-pilot system is designed to optimize the reflow process by monitoring and controlling various parameters such as temperature, time, and gas flow.

What is reflow soldering?

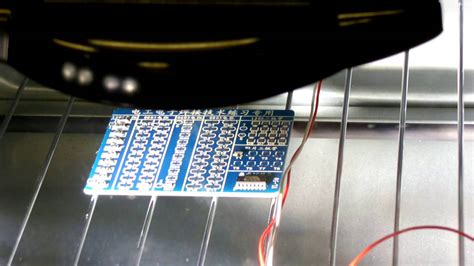

Reflow soldering is a process used in the assembly of electronic components onto printed circuit boards (PCBs). It involves applying solder paste to the PCB, placing the components onto the solder paste, and then heating the assembly in a reflow oven to melt the solder and form a permanent connection between the components and the PCB.

The reflow soldering process typically involves four stages:

- Preheat: The PCB and components are gradually heated to a temperature just below the melting point of the solder paste.

- Soak: The temperature is maintained for a period of time to allow the components and PCB to reach thermal equilibrium.

- Reflow: The temperature is rapidly increased to a peak temperature above the melting point of the solder, causing the solder to melt and form a connection between the components and the PCB.

- Cooling: The assembly is cooled down to room temperature, allowing the solder to solidify and form a permanent connection.

| Stage | Temperature Range | Time |

|---|---|---|

| Preheat | 150°C – 180°C | 60-90 sec |

| Soak | 180°C – 200°C | 60-120 sec |

| Reflow | 220°C – 250°C | 30-60 sec |

| Cooling | 25°C – 50°C | 60-120 sec |

The Rayming-reflow-pilot system is designed to precisely control these stages to ensure optimal solder joint formation.

Benefits of using Rayming-reflow-pilot

Improved solder joint quality

One of the main benefits of using the Rayming-reflow-pilot system is the improvement in solder joint quality. By precisely controlling the temperature profile during the reflow process, the system ensures that the solder melts and flows evenly, creating a strong and reliable connection between the components and the PCB.

The Rayming-reflow-pilot system also incorporates advanced features such as real-time temperature monitoring and closed-loop control, which allow for quick adjustments to be made to the temperature profile if necessary. This ensures that the solder joint quality remains consistent throughout the manufacturing process.

Increased productivity

Another benefit of using the Rayming-reflow-pilot system is increased productivity. The system is designed to optimize the reflow process, reducing the time required for each stage while still maintaining high-quality solder joints.

The Rayming-reflow-pilot system also includes features such as automatic conveyor speed control and multiple heating zones, which allow for faster throughput and increased production capacity. This can result in significant cost savings for manufacturers, as well as faster time-to-market for their products.

Reduced defects and rework

The precise control provided by the Rayming-reflow-pilot system also helps to reduce defects and rework. By ensuring that the solder joints are formed correctly the first time, the system minimizes the need for costly and time-consuming rework.

The system also includes features such as automatic profiling and data logging, which allow manufacturers to track and analyze the reflow process in real-time. This data can be used to identify potential issues and make adjustments to the process to prevent defects from occurring.

Key features of Rayming-reflow-pilot

Real-time temperature monitoring

One of the key features of the Rayming-reflow-pilot system is real-time temperature monitoring. The system uses advanced sensors to continuously measure the temperature of the PCB and components throughout the reflow process.

This real-time monitoring allows the system to quickly detect any deviations from the desired temperature profile and make adjustments to ensure that the solder joints are formed correctly. The system can also provide alerts to operators if the temperature exceeds certain thresholds, helping to prevent damage to the components or PCB.

Closed-loop control

Another important feature of the Rayming-reflow-pilot system is closed-loop control. This means that the system continuously compares the actual temperature profile to the desired profile and makes adjustments as necessary to maintain the correct temperature.

Closed-loop control is particularly important in the reflow soldering process, as even small deviations from the desired temperature profile can result in poor solder joint quality or damage to the components. By using closed-loop control, the Rayming-reflow-pilot system ensures that the temperature remains within tight tolerances throughout the process.

Automatic profiling and data logging

The Rayming-reflow-pilot system also includes automatic profiling and data logging features. Automatic profiling allows the system to automatically generate a temperature profile based on the specific characteristics of the PCB and components being soldered.

Data logging allows the system to record and store data on the temperature profile, conveyor speed, and other parameters for each reflow cycle. This data can be used for quality control purposes, as well as for troubleshooting and process optimization.

Multiple heating zones

The Rayming-reflow-pilot system also includes multiple heating zones, which allow for precise control of the temperature profile across the entire PCB. Each heating zone can be independently controlled, allowing the system to create a customized temperature profile for each specific PCB and component combination.

This level of control is particularly important for complex PCBs with a variety of components, as different components may require different temperature profiles for optimal solder joint formation. By using multiple heating zones, the Rayming-reflow-pilot system can ensure that each component receives the correct temperature profile, resulting in high-quality solder joints.

Applications of Rayming-reflow-pilot

The Rayming-reflow-pilot system is used in a wide range of electronics manufacturing applications, including:

Consumer electronics

The Rayming-reflow-pilot system is commonly used in the production of consumer electronics such as smartphones, tablets, and wearable devices. These products often have complex PCBs with a high density of components, requiring precise control of the reflow soldering process to ensure reliable and high-quality solder joints.

Automotive electronics

The Rayming-reflow-pilot system is also used in the production of automotive electronics, such as infotainment systems, sensors, and control modules. These products are subject to harsh environmental conditions and must be able to withstand extreme temperatures, vibrations, and shocks. The precise control provided by the Rayming-reflow-pilot system helps to ensure that these products are reliable and durable.

Medical devices

The Rayming-reflow-pilot system is also used in the production of medical devices, such as implantable devices, diagnostic equipment, and monitoring systems. These products must meet stringent quality and reliability standards, as they are often used in life-critical applications. The Rayming-reflow-pilot system helps to ensure that these products are manufactured to the highest standards of quality and reliability.

Aerospace and defense

The Rayming-reflow-pilot system is also used in the production of aerospace and defense electronics, such as avionics systems, communication equipment, and surveillance systems. These products must be able to withstand extreme environmental conditions and must meet strict reliability and performance requirements. The Rayming-reflow-pilot system helps to ensure that these products are manufactured to the highest standards of quality and reliability.

Conclusion

The Rayming-reflow-pilot system is a state-of-the-art technology that is revolutionizing the electronics manufacturing industry. By providing precise control of the reflow soldering process, the system helps to ensure high-quality and reliable solder joints, while also increasing productivity and reducing defects and rework.

The key features of the Rayming-reflow-pilot system, including real-time temperature monitoring, closed-loop control, automatic profiling and data logging, and multiple heating zones, make it an essential tool for electronics manufacturers looking to improve their production processes and maintain a competitive edge in the market.

With its wide range of applications in consumer electronics, automotive electronics, medical devices, and aerospace and defense, the Rayming-reflow-pilot system is poised to play an increasingly important role in the future of electronics manufacturing.

Frequently Asked Questions (FAQ)

What is the Rayming-reflow-pilot system?

The Rayming-reflow-pilot system is a state-of-the-art technology used in the manufacturing process of electronic components. It is designed to optimize the reflow soldering process by monitoring and controlling various parameters such as temperature, time, and gas flow.

What are the benefits of using the Rayming-reflow-pilot system?

The main benefits of using the Rayming-reflow-pilot system include improved solder joint quality, increased productivity, and reduced defects and rework. The system’s precise control of the reflow soldering process helps to ensure high-quality and reliable solder joints, while also reducing the time required for each stage of the process.

What are the key features of the Rayming-reflow-pilot system?

The key features of the Rayming-reflow-pilot system include real-time temperature monitoring, closed-loop control, automatic profiling and data logging, and multiple heating zones. These features allow the system to precisely control the reflow soldering process and ensure optimal solder joint formation.

What industries use the Rayming-reflow-pilot system?

The Rayming-reflow-pilot system is used in a wide range of electronics manufacturing applications, including consumer electronics, automotive electronics, medical devices, and aerospace and defense. The system’s precise control of the reflow soldering process makes it an essential tool for manufacturers in these industries.

How does the Rayming-reflow-pilot system improve solder joint quality?

The Rayming-reflow-pilot system improves solder joint quality by precisely controlling the temperature profile during the reflow soldering process. The system uses advanced sensors and closed-loop control to ensure that the solder melts and flows evenly, creating a strong and reliable connection between the components and the PCB. The system also includes features such as real-time temperature monitoring and automatic profiling, which help to prevent defects and ensure consistent solder joint quality.

No responses yet