Table of Contents

- Introduction to PCB Connectors

- Importance of Choosing the Right PCB Connector

- Types of PCB Connectors

3.1. Header Connectors

3.2. Edge Connectors

3.3. Board-to-Board Connectors

3.4. Wire-to-Board Connectors

3.5. Crimp Connectors

3.6. Coaxial Connectors

3.7. Power Connectors - Factors to Consider When Selecting PCB Connectors

4.1. Connector Pitch

4.2. Number of Pins

4.3. Current Rating

4.4. Voltage Rating

4.5. Mounting Type

4.6. Environmental Factors - PCB Connector Materials and Plating Options

- Best Practices for PCB Connector Selection and Installation

- Troubleshooting Common PCB Connector Issues

- Future Trends in PCB Connector Technology

- Frequently Asked Questions (FAQ)

- Conclusion

1. Introduction to PCB Connectors

PCB connectors are mechanical components that facilitate electrical connections between printed circuit boards (PCBs) and other devices or components. They play a critical role in ensuring reliable and efficient data transfer, power supply, and signal communication within electronic systems.

PCB connectors come in various shapes, sizes, and configurations, each designed to meet specific requirements and constraints. Understanding the different types of PCB connectors and their characteristics is essential for engineers, designers, and hobbyists working on electronic projects.

2. Importance of Choosing the Right PCB Connector

Selecting the appropriate PCB connector for your application is crucial for several reasons:

- Reliability: The right connector ensures a stable and secure connection, minimizing the risk of signal loss, power interruptions, or data corruption.

- Performance: Choosing a connector with the appropriate current and voltage ratings, as well as the required number of pins, guarantees optimal performance and prevents damage to the connected components.

- Space constraints: PCB real estate is often limited, so selecting a connector with the right size and mounting type is essential for efficient board layout and space utilization.

- Cost-effectiveness: Over-specifying or under-specifying a connector can lead to unnecessary expenses or performance issues. Choosing the right connector balances cost and functionality.

3. Types of PCB Connectors

There are several types of PCB connectors, each with its own unique features and applications. The following sections will discuss the most common types of PCB connectors in detail.

3.1. Header Connectors

Header connectors, also known as pin headers or box headers, are widely used in PCB designs for connecting wires, cables, or other PCBs. They consist of a row of male pins that can be soldered directly to the PCB. Header connectors are available in various sizes, pin counts, and pitches (the distance between the centers of adjacent pins).

| Pitch (mm) | Common Pin Counts |

|---|---|

| 1.27 | 2-40 |

| 2.00 | 2-20 |

| 2.54 | 2-40 |

Header connectors are often used in conjunction with female socket connectors, which provide a removable and reversible connection. Some common applications of header connectors include:

- Microcontroller and single-board computer (SBC) pins

- Programming and debugging interfaces

- Jumper connections for configuration settings

3.2. Edge Connectors

Edge connectors are designed to mate directly with the edge of a PCB, eliminating the need for additional connector components on the board itself. They are commonly used in applications where a daughterboard needs to be connected to a motherboard, such as in computer peripherals, expansion cards, and modular systems.

Edge connectors come in various form factors and pin counts, depending on the specific application. Some popular edge connector types include:

- PCI and PCIe connectors for computer expansion cards

- DIMM and SIMM connectors for memory modules

- Card edge connectors for custom daughterboard applications

When designing a PCB for use with an edge connector, it is essential to consider the following factors:

- PCB thickness and material

- Contact plating and finish

- Contact pitch and spacing

- Keying and polarization features to prevent incorrect insertion

3.3. Board-to-Board Connectors

Board-to-board (B2B) connectors are used to establish electrical connections between two PCBs that are positioned parallel or perpendicular to each other. These connectors provide a compact and reliable solution for interconnecting multiple boards in a system, enabling modular designs and efficient use of space.

B2B connectors are available in several configurations:

- Stacking connectors: These connectors allow boards to be stacked vertically, with male pins on one board mating with female receptacles on the other.

- Mezzanine connectors: Similar to stacking connectors, mezzanine connectors provide a higher stack height, allowing for additional components or clearance between boards.

- Orthogonal connectors: These connectors enable perpendicular board connections, with one board inserted into a receptacle on the other board at a 90-degree angle.

When choosing a B2B connector, consider the following factors:

- Stacking height and board spacing requirements

- Number of pins and rows

- Current and voltage ratings

- Mating cycles and durability

- Shielding and EMI protection, if necessary

3.4. Wire-to-Board Connectors

Wire-to-board (W2B) connectors are used to establish connections between individual wires or cables and a PCB. These connectors provide a reliable and secure method for attaching discrete wires to a board, allowing for power delivery, signal transmission, or data communication.

W2B connectors come in various styles and termination methods:

- Crimp connectors: These connectors use a crimping tool to secure the wire to a metal contact, which is then inserted into a housing that mates with the PCB.

- Insulation displacement connectors (IDC): IDC connectors pierce the wire insulation to establish a connection, eliminating the need for stripping the wire.

- Screw terminals: These connectors use a screw to secure the wire to a metal contact, providing a strong and removable connection.

- Soldered connectors: Some W2B connectors have leads that can be directly soldered to the PCB, providing a permanent connection.

When selecting a W2B connector, consider the following factors:

- Wire gauge and insulation diameter compatibility

- Current and voltage ratings

- Connector pitch and spacing

- Locking mechanisms and strain relief features

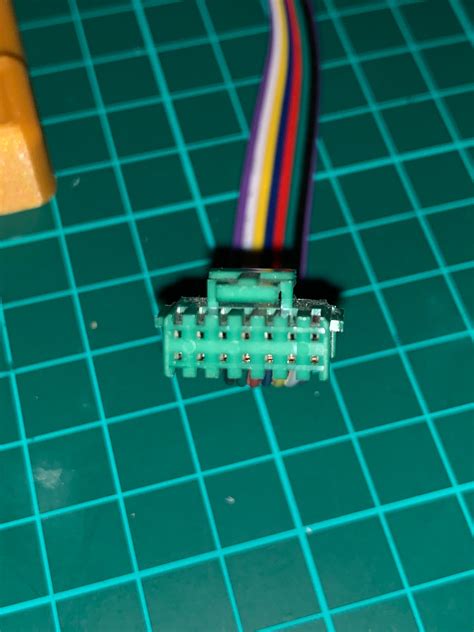

3.5. Crimp Connectors

Crimp connectors are a type of wire-to-board connector that uses a crimping process to establish a secure connection between a wire and a metal contact. The crimped contact is then inserted into a plastic housing, which mates with a corresponding receptacle on the PCB.

Crimp connectors offer several advantages:

- Reliability: Crimping provides a strong, gas-tight connection that is resistant to vibration and mechanical stress.

- Ease of assembly: Crimping is a quick and efficient process that can be automated for high-volume production.

- Removability: Crimp connectors allow for easy insertion and removal of wires, facilitating maintenance and repairs.

Some common types of crimp connectors include:

- Molex connectors: A popular family of crimp connectors used in various applications, such as power supplies, automotive systems, and consumer electronics.

- JST Connectors: A range of compact crimp connectors widely used in battery packs, sensors, and small electronic devices.

- Dupont connectors: A generic term for crimp connectors with a rectangular housing and a 2.54 mm pitch, often used in prototyping and hobbyist projects.

When using crimp connectors, it is essential to select the appropriate crimping tool and follow the manufacturer’s guidelines for crimp height, wire stripping, and insertion force to ensure a reliable connection.

3.6. Coaxial Connectors

Coaxial connectors are used to terminate coaxial cables, which are commonly used for transmitting high-frequency signals, such as radio frequency (RF) and video signals. These connectors provide a shielded, impedance-controlled connection that minimizes signal loss and interference.

Some popular types of coaxial connectors include:

- BNC (Bayonet Neill-Concelman): A quick-connect connector used in video, RF, and measurement applications.

- SMA (SubMiniature version A): A small, threaded connector used in high-frequency applications up to 18 GHz.

- SMB (SubMiniature version B): A smaller version of the SMA connector, used in applications up to 4 GHz.

- MCX (Micro Coaxial): A compact connector used in space-constrained applications, such as wireless devices and GPS receivers.

When selecting a coaxial connector for your PCB, consider the following factors:

- Frequency range and impedance matching requirements

- Cable compatibility and termination method

- Connector size and mounting style (surface-mount or through-hole)

- Environmental factors, such as moisture resistance and temperature range

3.7. Power Connectors

Power connectors are designed to deliver electrical power to a PCB from an external source, such as a power supply or battery. These connectors come in various shapes and sizes, depending on the voltage and current requirements of the application.

Some common types of power connectors include:

- Barrel connectors: Also known as cylindrical connectors, these are commonly used in low-voltage, low-current applications, such as wall adapters and chargers.

- Terminal blocks: These connectors use screw terminals to secure wires and are often used in industrial and high-power applications.

- Molex power connectors: A family of crimp connectors designed for power delivery, available in various pin counts and current ratings.

- IEC connectors: International Electrotechnical Commission (IEC) connectors, such as the IEC 60320 series, are used in mains-powered devices and provide a standardized interface for connecting power cords.

When choosing a power connector for your PCB, consider the following factors:

- Voltage and current ratings

- Connector size and mounting type

- Wire gauge compatibility

- Safety features, such as locking mechanisms and touch protection

4. Factors to Consider When Selecting PCB Connectors

When selecting PCB connectors for your application, several key factors must be taken into account to ensure optimal performance, reliability, and cost-effectiveness.

4.1. Connector Pitch

Connector pitch refers to the distance between the centers of adjacent pins or contacts in a connector. Smaller pitch connectors allow for higher pin density and more compact designs, but they may be more challenging to manufacture and assemble. Common connector pitches include:

- 1.27 mm (0.05 inches)

- 2.00 mm (0.079 inches)

- 2.54 mm (0.1 inches)

When selecting a connector pitch, consider the available PCB space, the required pin count, and the assembly process capabilities.

4.2. Number of Pins

The number of pins in a connector determines its ability to transfer signals, power, or data. More pins generally provide greater functionality but also increase the connector’s size and cost. When choosing the number of pins, consider the following:

- The number of signals or power lines required

- The need for additional pins for shielding, grounding, or keying

- The available PCB space and routing constraints

4.3. Current Rating

The current rating of a connector specifies the maximum amount of current that can safely flow through each pin. Exceeding this rating can lead to connector damage, overheating, or even fire. When selecting a connector, ensure that its current rating is sufficient for your application, taking into account any potential surge currents or transients.

4.4. Voltage Rating

The voltage rating of a connector indicates the maximum voltage that can be applied across its pins without causing insulation breakdown or arcing. As with current rating, it is essential to choose a connector with a voltage rating that meets or exceeds your application’s requirements.

4.5. Mounting Type

PCB connectors can be mounted on a board in several ways, depending on the application requirements and manufacturing process. The most common mounting types are:

- Through-hole mounting: Connector pins are inserted into plated holes in the PCB and soldered in place. This mounting type provides strong mechanical stability but requires more board space and manual assembly.

- Surface-mount technology (SMT): Connectors are placed on the surface of the PCB and soldered using reflow or wave soldering processes. SMT connectors are smaller and more suitable for automated assembly but may be less mechanically robust than through-hole connectors.

- Press-fit: Connector pins are pressed into unplated holes in the PCB, establishing an electrical connection through friction. Press-fit connectors eliminate the need for soldering but require precise hole sizing and controlled insertion force.

4.6. Environmental Factors

The environment in which your PCB will operate can significantly impact connector selection. Some environmental factors to consider include:

- Temperature range: Ensure that the connector materials and plating can withstand the expected operating temperature range without degradation or failure.

- Humidity and moisture: If your PCB will be exposed to high humidity or moisture, choose connectors with appropriate sealing or protection, such as IP-rated connectors or conformal coatings.

- Vibration and shock: In applications subject to mechanical stress, select connectors with robust locking mechanisms and strain relief features to prevent disconnection or damage.

- Electromagnetic interference (EMI): For sensitive or high-frequency applications, consider connectors with shielding or filtering capabilities to minimize EMI.

5. PCB Connector Materials and Plating Options

The materials and plating used in PCB connectors can significantly affect their performance, durability, and cost. The most common materials used in connector housings are:

- Nylon: A low-cost, lightweight, and insulating material suitable for general-purpose applications.

- Polyester: Offers better temperature resistance and mechanical strength than nylon.

- Polycarbonate: Provides high impact resistance and temperature stability, making it suitable for harsh environments.

- Liquid Crystal Polymer (LCP): A high-performance material with excellent electrical properties, dimensional stability, and chemical resistance.

Connector pins and contacts are typically made from copper alloys, such as brass or phosphor bronze, due to their good electrical conductivity and mechanical properties. These base materials are often plated with various finishes to improve performance and durability:

- Gold: Offers excellent corrosion resistance, electrical conductivity, and wear resistance, making it ideal for high-reliability applications. However, gold plating is expensive.

- Nickel: Provides good corrosion resistance and mechanical strength at a lower cost than gold. Nickel is often used as an underplate for gold or as a standalone finish.

- Tin: A low-cost plating option that offers good solderability and corrosion resistance. However, tin is prone to whisker growth, which can cause short circuits.

- Silver: Provides excellent electrical conductivity and corrosion resistance but is less wear-resistant than gold and can tarnish over time.

When selecting connector materials and plating, consider the following factors:

- Environmental conditions and corrosion resistance requirements

- Mating cycles and wear resistance needs

- Signal integrity and electrical performance

- Cost and availability

6. Best Practices for PCB Connector Selection and Installation

To ensure optimal performance and reliability of your PCB connectors, follow these best practices:

- Carefully consider the connector requirements: Thoroughly evaluate your application’s electrical, mechanical, and environmental requirements before selecting a connector.

- Use trusted suppliers and manufacturers: Source connectors from reputable suppliers and manufacturers to ensure quality and reliability.

- Follow the manufacturer’s specifications: Adhere to the manufacturer’s guidelines for PCB layout, hole sizes, pad dimensions, and assembly processes to ensure proper fit and function.

- Design for manufacturability: Consider the assembly process and available equipment when selecting connectors and designing your PCB layout.

- Use appropriate strain relief: Incorporate strain relief features, such as cable clamps or adhesive-lined heat shrink tubing, to prevent mechanical stress on the connector.

- Implement keying and polarization: Use connectors with keying or polarization features to prevent incorrect mating and potential damage.

- Ensure proper grounding and shielding: For connectors carrying sensitive or high-frequency signals, provide appropriate grounding and shielding to minimize EMI and signal integrity issues.

- Follow ESD precautions: Handle connectors and PCBs with care, following electrostatic discharge (ESD) precautions to prevent damage to sensitive components.

- Inspect and test: Visually inspect connectors for proper installation and perform functional tests to ensure correct operation and reliability.

7. Troubleshooting Common PCB Connector Issues

Despite best efforts, PCB connector issues can still arise. Some common problems and their potential solutions

No responses yet