How Does an AOI Test Work?

An AOI test system typically consists of the following components:

- One or more high-resolution digital cameras to capture images of the PCB or component being inspected

- Bright, uniform lighting to illuminate the test subject

- A motorized gantry system to precisely position the cameras

- Image processing software to analyze the captured images and identify defects

- A user interface for programming inspection routines and viewing results

The basic operation of an AOI test involves:

- The PCB or component to be tested is loaded into the AOI machine, often by automated conveyor.

- The cameras capture high-resolution images of the entire surface from multiple angles.

- Sophisticated image recognition algorithms process the images and compare them against a “golden sample” or CAD data to identify any deviations or anomalies.

- Defects such as missing/incorrect components, solder bridges, insufficient solder, etc. are flagged.

- The PCB is marked as passed or failed based on predefined failure criteria. Failed boards are diverted for rework or scrap.

Benefits of AOI Testing

Incorporating AOI testing into an electronics manufacturing line provides several key benefits:

Early Defect Detection

AOI allows defects to be caught early in the production process, before later value-added steps like final assembly and functional test. Finding and fixing defects early minimizes scrap and rework.

Improved Quality

By screening out defects, AOI helps ensure that only high-quality product leaves the factory. This improves end customer satisfaction and reduces warranty claims.

Increased Throughput

AOI systems can inspect PCBs much faster than human operators, often in a matter of seconds. This allows high volume production without compromising quality.

Reduced Labor Costs

Automated inspection reduces reliance on human inspectors, which saves labor costs. Skilled operators are only needed to program the system and analyze failures.

Consistent, Repeatable Results

Unlike human inspectors, AOI systems don’t get fatigued and can consistently apply the same inspection criteria. Results are repeatable across shifts and factories.

Types of AOI Systems

AOI test equipment comes in several different configurations to suit different use cases:

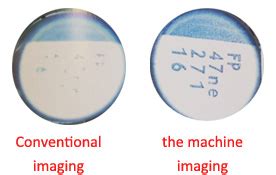

2D AOI

2D AOI systems use orthogonally mounted cameras (from directly above) to capture 2-dimensional images of the PCB surface. These systems are the most common and lowest cost but can miss some defects on tall components or in shadowed areas.

2.5D AOI

2.5D AOI adds angled side cameras to also capture the component bodies from the side. This provides a form of “pseudo 3D” imaging to better inspect component height and coplanarity without full 3D capability.

3D AOI

True 3D AOI uses special imaging techniques like structured light or laser scanning to capture a full 3-dimensional height map of the PCB surface. This allows measurement of coplanarity, component height/tilt, and other defects difficult to catch in 2D.

Combined 2D/3D

Many newer AOI platforms combine conventional 2D image capture with 3D height mapping for best of both worlds performance. 2D is used for quick inspection of solder joints and flat features while 3D covers parts requiring height/tilt measurement.

Limitations of AOI Testing

While AOI test provides many advantages, it’s important to understand its limitations:

- Cannot detect internal or hidden defects like BGA opens, voids, etc. X-ray is still required for those.

- Can be fooled by lighting/shadows, reflections, or low-contrast defects.

- Requires significant programming and tuning for each new PCB design.

- Limited ability to measure actual values (resistance, capacitance, etc.).

For these reasons, AOI is rarely used as the sole inspection method but rather as a complement to other techniques like flying probe electrical test, boundary scan, and human visual inspection.

Selecting an AOI Test System

With many different AOI platforms on the market, it can be challenging to select the right one for a given production line. Here are some key factors to consider:

| Factor | Description |

|---|---|

| Defect Coverage | 2D, 2.5D, 3D, or combined system? Optical resolution and lighting options? |

| Speed | Specified in PCBs per hour (PPH) for a particular PCB size and defect mix. |

| Automation | Manual loading or inline automated handling? SMEMA, side, or top board conveyors? |

| Ease of Programming | CAD data import formats? User interface? Self-programming capabilities? |

| Factory Integration | Machine vision standards? MES/traceability software interfaces? Remote support? |

| Cost | Upfront capital costs and long term consumables, maintenance, etc. |

It’s best to evaluate multiple systems with real-world product samples and engage with industry peers for their experiences before making a selection.

The Future of AOI Testing

As electronics continue to miniaturize and increase in complexity, AOI technology must evolve to keep up. Some key trends to watch include:

- Higher resolution cameras and 3D imaging for shrinking footprints

- Multi-color and multi-spectral lighting for challenging surfaces

- Deep learning AI to speed programming and handle greater variation

- Tighter integration with “smart factory” MES and traceability systems

- More use of AOI for permanent record of inspection results, not just pass/fail

Despite the rise of newer techniques like SPI and CT AXI, don’t expect AOI to go away anytime soon. It remains one of the most versatile, cost-effective ways to improve electronics quality assurance.

FAQ

What types of defects can AOI detect?

A: AOI is effective at finding common PCB defects like missing/wrong components, tombstoning, billboarding, insufficient or bridged solder joints, lifted leads, and visible damage. It is less effective at internal, under-component, and low-contrast defects.

How much does an AOI machine cost?

A: AOI system prices range from around $50,000 USD for a basic benchtop 2D system to over $500,000 for an inline 3D platform with full automation. Most machines fall in the $100-300K range.

How fast is an AOI test system?

A: Inspection speeds vary widely based on PCB size, component density, defect types, and imaging technology. Typical ranges are 30-50 PCBs/hour for larger boards with 3D inspection up to 200+ PCBs/hour for small PCBs with 2D-only. The fastest 2D systems can exceed 1000 PCBs/hour under ideal conditions.

Can AOI be used for first article inspection?

A: Yes, AOI is an excellent tool for first article inspection (FAI) on new PCB designs. It provides a detailed visual record of the first production samples that can be reviewed by engineering and quality teams. Many AOI software packages include specific FAI modes and reporting.

Is AOI testing required for automotive electronics?

A: While not explicitly mandated, AOI testing is a key part of meeting the strict quality requirements of automotive electronics standards like IATF 16949 and VDA 6.3. Most automotive OEMs and Tier 1 suppliers use AOI on any safety-critical electronics as part of a multi-stage inspection process.

No responses yet