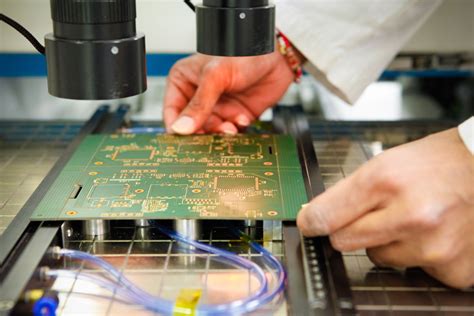

Introduction to PCB Manufacturing

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device, from smartphones and computers to medical equipment and aerospace technology. PCB manufacturing is a complex process that involves multiple steps, including design, fabrication, assembly, and testing. The global PCB market is highly competitive, with manufacturers located in various countries around the world. Two of the biggest players in the PCB manufacturing industry are China and the United States. In this article, we will compare PCB manufacturing in China and the US, examining factors such as cost, quality, lead time, and technological capabilities.

Overview of the PCB Manufacturing Industry

The PCB manufacturing industry has grown significantly in recent years, driven by the increasing demand for electronic devices and the rapid pace of technological innovation. According to a report by Grand View Research, the global PCB market size was valued at USD 60.2 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2021 to 2028. The Asia Pacific region, particularly China, dominates the global PCB market, accounting for over 50% of the market share.

Market Share of PCB Manufacturing by Region

| Region | Market Share |

|---|---|

| Asia Pacific | 54.7% |

| North America | 18.3% |

| Europe | 17.1% |

| Rest of World | 9.9% |

Source: Grand View Research, 2021

PCB Manufacturing in China

China has been the world’s largest PCB manufacturer for over a decade, with a market share of over 50%. The country’s PCB industry has grown rapidly due to several factors, including low labor costs, government support, and a well-established supply chain. China’s PCB manufacturers offer a wide range of services, from low-cost, high-volume production to advanced, high-tech PCBs for specialized applications.

Advantages of PCB Manufacturing in China

- Lower production costs due to cheaper labor and materials

- Extensive supply chain network, making it easier to source components

- Faster turnaround times due to efficient manufacturing processes

- Government support and incentives for the electronics industry

- Ability to handle high-volume orders

Disadvantages of PCB Manufacturing in China

- Concerns over intellectual property protection and security

- Language and cultural barriers can lead to communication issues

- Potential quality control issues, particularly with low-cost manufacturers

- Longer shipping times and higher transportation costs for overseas customers

- Geopolitical tensions and trade disputes can disrupt supply chains

PCB Manufacturing in the United States

The United States has a long history of PCB manufacturing, with a focus on high-end, specialized applications such as military, aerospace, and medical devices. While the US PCB industry has faced challenges in recent years due to offshore competition, it remains a significant player in the global market, particularly in the high-tech segment.

Advantages of PCB Manufacturing in the United States

- Strict quality control standards and regulations ensure high-quality products

- Strong intellectual property protection and security measures

- Advanced technological capabilities for complex, high-performance PCBs

- Proximity to customers in North America, reducing shipping times and costs

- Skilled workforce with expertise in PCB design and manufacturing

Disadvantages of PCB Manufacturing in the United States

- Higher production costs due to more expensive labor and materials

- Longer lead times compared to some offshore manufacturers

- Limited supply chain network, making it more challenging to source components

- Smaller manufacturing capacity compared to China and other Asian countries

- Regulatory compliance can be costly and time-consuming

Comparing PCB Manufacturing in China and the US

When deciding between PCB manufacturers in China and the US, there are several key factors to consider, including cost, quality, lead time, and technological capabilities.

Cost Comparison

One of the primary reasons many companies choose to manufacture PCBs in China is the lower production costs. Chinese manufacturers can offer significantly lower prices due to cheaper labor, materials, and overhead costs. However, it is essential to consider the total cost of ownership, including shipping, tariffs, and potential quality issues, when comparing prices between Chinese and US manufacturers.

Quality Comparison

While China’s PCB industry has made significant strides in improving quality in recent years, the US still holds an advantage in terms of strict quality control standards and regulations. US manufacturers are required to adhere to stringent guidelines, such as IPC standards, which ensure consistent, high-quality products. Chinese manufacturers, particularly low-cost providers, may not always meet these standards, leading to potential quality issues.

Lead Time Comparison

Lead time is another crucial factor to consider when choosing a PCB manufacturer. Chinese manufacturers often have faster turnaround times due to their efficient manufacturing processes and extensive supply chain network. However, shipping times from China to other countries can be longer, which may offset some of the lead time advantages. US manufacturers may have slightly longer lead times, but their proximity to North American customers can result in faster overall delivery times.

Technological Capabilities Comparison

Both China and the US have advanced technological capabilities in PCB manufacturing, but the US holds an edge in high-end, specialized applications. US manufacturers are known for their expertise in complex, multi-layer PCBs, high-frequency PCBs, and advanced substrate materials. Chinese manufacturers, while capable of producing a wide range of PCBs, may not have the same level of expertise in these niche areas.

Choosing Between China and US PCB Manufacturers

When deciding between PCB manufacturers in China and the US, it is essential to carefully consider your specific requirements and priorities. If cost is the primary concern and you require high-volume, low-complexity PCBs, a Chinese manufacturer may be the best choice. However, if quality, intellectual property protection, and advanced technological capabilities are more important, a US manufacturer may be the better option.

It is also worth considering a hybrid approach, where you work with both Chinese and US manufacturers depending on the specific project requirements. This can allow you to take advantage of the strengths of each region while mitigating the potential risks and drawbacks.

Future Trends in PCB Manufacturing

As the demand for electronic devices continues to grow and technology advances, the PCB manufacturing industry is poised for further growth and innovation. Some of the key trends shaping the future of PCB manufacturing include:

- Miniaturization: The trend towards smaller, more compact electronic devices is driving the need for smaller, higher-density PCBs.

- Advanced materials: New substrate materials, such as high-frequency laminates and flexible substrates, are enabling the development of more advanced, specialized PCBs.

- Automation and Industry 4.0: The adoption of automated manufacturing processes and smart factory technologies is increasing efficiency and reducing costs in PCB manufacturing.

- Environmental sustainability: There is a growing focus on environmentally friendly PCB manufacturing practices, such as the use of lead-free materials and the reduction of waste and emissions.

- 5G and IoT: The rollout of 5G networks and the growth of the Internet of Things (IoT) are creating new opportunities for PCB manufacturers, particularly in the areas of high-frequency and high-speed PCBs.

Conclusion

PCB manufacturing is a critical industry that plays a vital role in the global electronics market. China and the United States are two of the biggest players in the PCB manufacturing industry, each with its own strengths and weaknesses. When choosing between PCB manufacturers in China and the US, it is essential to carefully consider factors such as cost, quality, lead time, and technological capabilities, as well as your specific project requirements.

As the PCB manufacturing industry continues to evolve and innovate, it is likely that both China and the US will remain significant players in the global market. By understanding the advantages and disadvantages of each region and making informed decisions based on your specific needs, you can ensure that you choose the best PCB manufacturer for your projects.

Frequently Asked Questions (FAQ)

-

Q: What are the main differences between PCB manufacturing in China and the US?

A: The main differences between PCB manufacturing in China and the US include cost, quality control standards, lead times, and technological capabilities. Chinese manufacturers generally offer lower costs and faster turnaround times, while US manufacturers typically have stricter quality control standards and more advanced technological capabilities for high-end, specialized applications. -

Q: Is it always cheaper to manufacture PCBs in China compared to the US?

A: While PCB Manufacturing Costs are generally lower in China due to cheaper labor and materials, it is essential to consider the total cost of ownership, including shipping, tariffs, and potential quality issues. In some cases, the cost savings of manufacturing in China may be offset by these additional factors. -

Q: How do I ensure the quality of PCBs manufactured in China?

A: To ensure the quality of PCBs manufactured in China, it is important to work with reputable manufacturers that have a proven track record of producing high-quality products. You should also establish clear quality control standards and requirements, and consider conducting regular audits and inspections to verify compliance. -

Q: What are the advantages of manufacturing PCBs in the US?

A: The advantages of manufacturing PCBs in the US include strict quality control standards and regulations, strong intellectual property protection, advanced technological capabilities for complex, high-performance PCBs, proximity to North American customers, and a skilled workforce with expertise in PCB design and manufacturing. -

Q: Can I work with both Chinese and US PCB manufacturers for different projects?

A: Yes, adopting a hybrid approach where you work with both Chinese and US PCB manufacturers depending on the specific project requirements can be an effective strategy. This allows you to take advantage of the strengths of each region while mitigating the potential risks and drawbacks.

No responses yet