Introduction to Blue PCBs

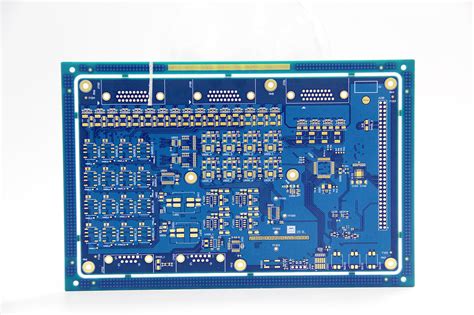

Blue printed circuit boards (PCBs) are a common sight in the electronics industry. These distinctive blue boards are used in a wide range of applications, from consumer electronics to industrial equipment. But why are some circuit boards blue, and what are the advantages of using blue PCBs?

What are PCBs?

Before diving into the specifics of blue PCBs, let’s first understand what PCBs are. PCBs are the foundation of modern electronics. They are thin, flat boards made of insulating materials, such as fiberglass or plastic, with conductive copper traces etched onto their surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits, to create a functional electronic device.

The History of Blue PCBs

The use of blue PCBs dates back to the early days of the electronics industry. In the 1960s and 1970s, PCBs were typically green in color due to the solder mask used to protect the copper traces. However, as the industry evolved, manufacturers began experimenting with different colors for their PCBs.

Blue PCBs gained popularity in the 1980s and 1990s, particularly in the computer and telecommunications industries. The distinctive blue color made it easier for technicians to identify and troubleshoot components on the board, especially in low-light conditions.

Advantages of Blue PCBs

There are several advantages to using blue PCBs in electronic devices. Let’s explore some of the key benefits.

1. Enhanced Visibility

One of the primary reasons for using blue PCBs is enhanced visibility. The blue color provides a high contrast against the white silkscreen markings and silver-colored components on the board. This makes it easier for technicians to identify and work with individual components, even in low-light conditions.

| PCB Color | Contrast with Silkscreen | Contrast with Components |

|---|---|---|

| Blue | High | High |

| Green | Medium | Low |

| Red | Low | Medium |

| Yellow | Low | Low |

As the table above illustrates, blue PCBs offer the highest contrast with both silkscreen markings and components, making them the most visually accessible option.

2. Improved Inspection

Blue PCBs also facilitate improved inspection during the manufacturing process. The high contrast between the blue substrate and the copper traces makes it easier for automated optical inspection (AOI) systems to detect defects, such as short circuits or missing components.

3. Reduced Eye Strain

Working with electronic components can be visually demanding, particularly when dealing with intricate designs or small components. The high contrast of blue PCBs can help reduce eye strain for technicians and engineers who spend long hours working with these boards.

4. Aesthetic Appeal

In addition to their functional benefits, blue PCBs also have an aesthetic appeal. The distinctive blue color can make electronic devices more visually interesting and help them stand out in a crowded market.

Manufacturing Process of Blue PCBs

The manufacturing process for blue PCBs is similar to that of other PCBs, with a few key differences. Let’s take a closer look at the steps involved.

1. Substrate Preparation

The first step in manufacturing a blue PCB is to prepare the substrate. The substrate is typically made of fiberglass or a similar insulating material, and it is cut to the desired size and shape.

2. Copper Lamination

Next, a thin layer of copper is laminated onto the substrate using heat and pressure. This copper layer will form the conductive traces that connect the electronic components on the board.

3. Photoresist Application

A photoresist, a light-sensitive material, is then applied to the copper layer. This photoresist will be used to create the desired pattern of copper traces on the board.

4. Exposure and Development

The photoresist-coated board is then exposed to light through a photomask, which contains the desired circuit pattern. The exposed areas of the photoresist become soluble and are removed during the development process, leaving behind the unexposed areas that will form the copper traces.

5. Etching

The board is then subjected to an etching process, which removes the unwanted copper from the areas not protected by the photoresist. This leaves behind the desired pattern of copper traces on the board.

6. Solder Mask Application

A blue solder mask is then applied to the board, covering the copper traces and leaving only the areas where components will be soldered exposed. This solder mask is what gives blue PCBs their distinctive color.

7. Silkscreen Printing

Finally, white silkscreen markings are printed onto the board to label components and provide other important information for assembly and troubleshooting.

Applications of Blue PCBs

Blue PCBs are used in a wide range of electronic devices and applications. Some common examples include:

- Computers and servers

- Telecommunications equipment

- Industrial control systems

- Medical devices

- Automotive electronics

- Consumer electronics

The enhanced visibility and improved inspection capabilities of blue PCBs make them particularly well-suited for applications where reliability and ease of maintenance are critical.

Frequently Asked Questions (FAQ)

1. Are blue PCBs more expensive than other colors?

In general, the cost difference between blue PCBs and other colors is minimal. The primary factors that affect PCB cost are the size, complexity, and quantity of the boards being manufactured.

2. Can blue PCBs be used for high-frequency applications?

Yes, blue PCBs can be used for high-frequency applications. The color of the solder mask does not affect the electrical properties of the board.

3. Are there any disadvantages to using blue PCBs?

There are no significant disadvantages to using blue PCBs. However, some manufacturers may have a preference for other colors based on their specific needs or aesthetic preferences.

4. Can blue PCBs be manufactured with different surface finishes?

Yes, blue PCBs can be manufactured with a variety of surface finishes, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative).

5. Are there any specific industries that prefer blue PCBs?

Blue PCBs are widely used across various industries, but they are particularly popular in the computer, telecommunications, and industrial control sectors due to their enhanced visibility and improved inspection capabilities.

Conclusion

Blue PCBs have become a common sight in the electronics industry, offering a range of benefits over other PCB colors. From enhanced visibility and improved inspection to reduced eye strain and aesthetic appeal, blue PCBs have proven to be a reliable and visually appealing choice for a wide range of applications.

As the electronics industry continues to evolve, it is likely that blue PCBs will remain a popular choice for manufacturers and designers alike. With their combination of functional benefits and distinctive appearance, blue PCBs are well-positioned to meet the demands of an increasingly complex and competitive market.

No responses yet