Introduction to LED PCB Assembly

Light-emitting diode (LED) technology has revolutionized the lighting industry, offering energy-efficient, long-lasting, and versatile solutions for a wide range of applications. LED PCB assembly plays a crucial role in the production of LED lighting products, combining the power of LEDs with the functionality and reliability of printed circuit boards (PCBs). In this comprehensive article, we will explore the world of LED PCB assembly, discussing its benefits, applications, design considerations, manufacturing processes, and frequently asked questions.

What is LED PCB?

An LED PCB is a printed circuit board specifically designed to support and connect LED components. These specialized PCBs provide the necessary electrical connections, heat dissipation, and mechanical stability required for optimal LED performance. LED PCBs can be customized to accommodate various LED configurations, sizes, and power requirements, making them suitable for a broad spectrum of lighting applications.

Benefits of LED PCB Assembly

LED PCB assembly offers numerous advantages over traditional lighting solutions:

- Energy Efficiency: LEDs consume significantly less power compared to incandescent and fluorescent lights, resulting in substantial energy savings.

- Long Lifespan: LED PCBs are designed to withstand the test of time, with LEDs lasting up to 50,000 hours or more, reducing maintenance and replacement costs.

- Versatility: LED PCBs can be customized to fit various form factors and designs, enabling their use in a wide range of applications, from compact indicators to large-scale lighting installations.

- Eco-Friendly: LEDs contain no toxic materials, such as mercury, and are fully recyclable, making them an environmentally friendly lighting choice.

- Instant On/Off: Unlike traditional lighting sources, LEDs reach full brightness instantly and can be switched on and off rapidly without affecting their lifespan.

Applications of LED PCB Assembly

LED PCB assembly finds its way into numerous applications across various industries:

1. General Lighting

LED PCBs are widely used in general lighting applications, including:

- Residential lighting (e.g., bulbs, downlights, and strip lights)

- Commercial lighting (e.g., office, retail, and hospitality spaces)

- Industrial lighting (e.g., warehouses, factories, and parking lots)

- Outdoor lighting (e.g., street lights, landscape lighting, and signage)

2. Automotive Lighting

LED PCBs have become increasingly popular in the automotive industry, offering improved visibility, style, and efficiency:

- Headlights and taillights

- Interior lighting (e.g., dashboard, cabin, and ambient lighting)

- Daytime running lights (DRLs)

- Turn signals and brake lights

3. Backlighting

LED PCBs are used for backlighting various displays and panels:

- LCD and OLED displays (e.g., televisions, monitors, and smartphones)

- Instrument panels and gauges

- Signage and advertising displays

4. Medical and Scientific Equipment

LED PCBs are employed in medical and scientific applications, providing precise and reliable illumination:

- Medical diagnostic devices (e.g., microscopes, endoscopes, and imaging systems)

- Surgical lighting and headlamps

- Laboratory equipment (e.g., spectrophotometers and fluorescence microscopes)

5. Horticulture Lighting

LED PCBs are increasingly used in horticulture lighting to promote plant growth and health:

- Grow lights for indoor farming and greenhouses

- Vertical farming and hydroponic systems

- Supplemental lighting for nurseries and research facilities

LED PCB Design Considerations

Designing an LED PCB requires careful consideration of several factors to ensure optimal performance, reliability, and longevity:

1. LED Selection

Choosing the right LEDs for your application is crucial. Consider the following aspects:

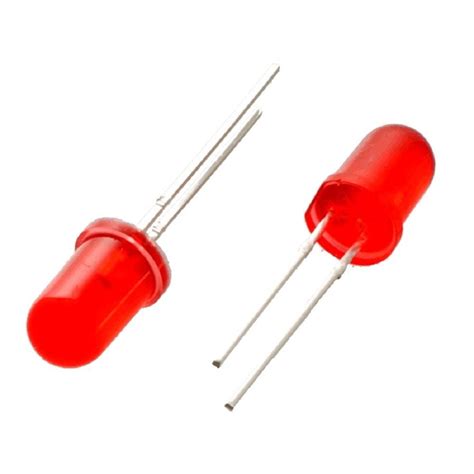

- LED type (e.g., through-hole, surface-mount, or chip-on-board)

- Color temperature and wavelength

- Luminous flux and efficacy

- Forward voltage and current

- Viewing angle and beam pattern

2. Thermal Management

Proper thermal management is essential for LED PCBs to prevent overheating and ensure stable performance:

- Use of metal-core PCBs (MCPCBs) or aluminum PCBs for enhanced heat dissipation

- Incorporation of heat sinks, thermal vias, and thermal interface materials (TIMs)

- Adequate spacing between LEDs to minimize thermal interaction

- Consideration of ambient temperature and airflow in the operating environment

3. Electrical Design

Designing the electrical circuitry for LED PCBs involves the following considerations:

- Power supply selection (e.g., constant current or constant voltage)

- Current limiting and voltage regulation

- LED driver selection and configuration

- Proper sizing of traces and vias to handle the required current

- Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) considerations

4. Optical Design

Optimizing the optical performance of LED PCBs requires attention to the following aspects:

- Lens and reflector design for desired beam pattern and light distribution

- Diffuser and mixing chamber design for uniform color and brightness

- Consideration of color rendering index (CRI) and color consistency

- Minimization of glare and visual discomfort

5. Mechanical Design

The mechanical design of LED PCBs should address the following factors:

- PCB material selection (e.g., FR-4, metal-core, or flexible PCBs)

- Mounting and assembly methods (e.g., through-hole, surface-mount, or mixed technology)

- Dimensional constraints and form factor requirements

- Vibration and shock resistance

- Environmental protection (e.g., conformal coating, encapsulation, or IP rating)

LED PCB Manufacturing Process

The manufacturing process for LED PCBs involves several key steps:

-

PCB Fabrication: The PCB is fabricated using standard processes, such as etching, drilling, and plating, based on the design files provided.

-

Solder Paste Application: Solder paste is applied to the PCB pads using a stencil or screen printing process, ensuring precise deposition of the solder material.

-

LED Placement: LEDs are placed onto the PCB using automated pick-and-place machines, ensuring accurate positioning and orientation.

-

Reflow Soldering: The PCB with LEDs undergoes a reflow soldering process, where the solder paste melts and forms a reliable electrical and mechanical connection between the LEDs and the PCB.

-

Inspection and Testing: The assembled LED PCB is inspected for defects, such as solder bridges, open circuits, or misaligned components. Functional testing is performed to ensure proper LED operation and performance.

-

Conformal Coating and Encapsulation (Optional): Depending on the application and environmental requirements, the LED PCB may undergo conformal coating or encapsulation to protect the components from moisture, dust, and other contaminants.

-

Final Assembly: The LED PCB is integrated into the final lighting product, which may involve additional steps such as housing assembly, lens installation, and wiring.

Frequently Asked Questions (FAQ)

1. What is the difference between an LED PCB and a regular PCB?

An LED PCB is specifically designed to support and connect LED components, providing the necessary electrical, thermal, and mechanical properties required for optimal LED performance. Regular PCBs, on the other hand, are designed for general-purpose electronic circuits and may not have the specific features needed for LED applications.

2. Can LED PCBs be customized to fit my specific application?

Yes, LED PCBs can be customized to accommodate various LED configurations, sizes, power requirements, and form factors. This flexibility allows LED PCBs to be tailored to meet the specific needs of your application, ensuring optimal performance and functionality.

3. What are the benefits of using metal-core PCBs (MCPCBs) for LED applications?

Metal-core PCBs (MCPCBs) offer superior thermal conductivity compared to traditional FR-4 PCBs. The metal core, typically made of aluminum, helps to efficiently dissipate heat generated by the LEDs, preventing overheating and ensuring stable performance. This is particularly important for high-power LED applications where thermal management is critical.

4. How do I select the appropriate LED driver for my LED PCB?

Selecting the appropriate LED driver depends on several factors, including the number of LEDs, their forward voltage and current requirements, the desired dimming capability, and the power supply specifications. It is essential to choose an LED driver that can provide the necessary current and voltage while ensuring compatibility with your LED PCB design and power supply.

5. What are the key considerations for ensuring color consistency in LED PCB applications?

To ensure color consistency in LED PCB applications, consider the following factors:

- Use LEDs with tight color binning tolerances to minimize variations in color temperature and hue.

- Implement proper thermal management to prevent color shifts due to temperature fluctuations.

- Employ color mixing techniques, such as diffusers and mixing chambers, to achieve uniform color distribution.

- Conduct thorough testing and calibration to ensure color consistency across multiple LED PCBs and lighting fixtures.

Conclusion

LED PCB assembly is a critical aspect of modern lighting solutions, offering energy efficiency, versatility, and long-lasting performance. By understanding the benefits, applications, design considerations, and manufacturing processes involved in LED PCB assembly, engineers and manufacturers can create innovative and reliable lighting products that meet the ever-growing demands of various industries.

As LED technology continues to advance, LED PCBs will play an increasingly vital role in shaping the future of lighting. With the ability to customize LED PCBs for specific applications and the ongoing development of more efficient and cost-effective manufacturing processes, the possibilities for LED lighting solutions are virtually limitless.

By partnering with experienced LED PCB assembly providers and staying up-to-date with the latest industry trends and best practices, businesses can unlock the full potential of LED lighting and stay ahead of the competition in this rapidly evolving field.

| LED PCB Assembly Comparison | Traditional PCBs | LED PCBs |

|---|---|---|

| Thermal Management | Limited | Enhanced |

| Electrical Design | General-purpose | LED-specific |

| Optical Design | Not applicable | Critical |

| Mechanical Design | Standard | Customizable |

| Applications | Broad | Lighting-focused |

In summary, LED PCB assembly is a one-stop solution for creating cutting-edge LED lighting products that combine energy efficiency, durability, and adaptability. By leveraging the power of LED PCBs and partnering with experienced assembly providers, businesses can illuminate the path to a brighter, more sustainable future.

No responses yet