Introduction to Digital PCB

In the world of electronics, printed circuit boards (PCBs) play a crucial role in connecting and supporting various electronic components. Among the different types of PCBs, digital PCBs have gained significant importance due to their ability to process and transmit binary digital signals. These circuits have revolutionized the electronics industry by enabling faster, more reliable, and more efficient processing of digital data.

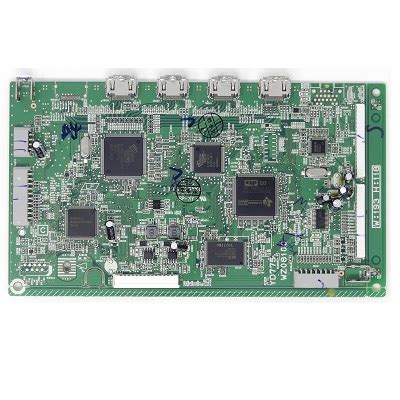

What is a Digital PCB?

A digital PCB is a printed circuit board designed specifically to handle binary digital signals. Unlike analog PCBs, which deal with continuous signals, digital PCBs operate with discrete voltage levels representing logical “0” and “1” states. These boards are engineered to minimize signal distortion, ensure proper timing, and maintain signal integrity throughout the circuit.

Key Components of a Digital PCB

To function effectively, a digital PCB incorporates several essential components:

- Microprocessor or Microcontroller: The brain of the digital circuit, responsible for executing instructions and processing data.

- Memory Devices: Components that store data and programs, such as RAM (Random Access Memory) and ROM (Read-Only Memory).

- Logic Gates: Basic building blocks of digital circuits that perform logical operations like AND, OR, NOT, and XOR.

- Flip-Flops and Registers: Sequential logic devices that store and synchronize data within the circuit.

- Oscillators and Clock Generators: Components that provide timing signals to synchronize the operation of various elements on the PCB.

Advantages of Digital PCBs

1. High-Speed Processing

One of the primary advantages of digital PCBs is their ability to process data at incredibly high speeds. With the use of high-frequency clock signals and optimized circuit designs, digital PCBs can execute complex calculations and transmit data rapidly. This high-speed processing capability is essential for applications that require real-time response, such as gaming systems, high-performance computing, and communication networks.

2. Noise Immunity

Digital PCBs exhibit excellent noise immunity compared to their analog counterparts. Binary digital signals have a higher tolerance for electrical noise and interference, as they operate with distinct voltage levels. This noise immunity ensures that the integrity of the digital data remains intact, even in environments with electromagnetic interference (EMI) or other sources of noise.

3. Scalability and Flexibility

Digital PCBs offer great scalability and flexibility in terms of design and functionality. With the use of programmable devices like microcontrollers and FPGAs (Field-Programmable Gate Arrays), digital circuits can be easily modified and updated without requiring physical changes to the PCB. This flexibility allows for rapid prototyping, customization, and future upgrades, making digital PCBs adaptable to evolving requirements.

4. Cost-Effectiveness

The widespread adoption of digital technologies has led to the availability of cost-effective digital components and manufacturing processes. Mass production of digital ICs (Integrated Circuits) and the use of surface-mount technology (SMT) have significantly reduced the cost of fabricating digital PCBs. Additionally, the ability to integrate multiple functions onto a single chip further enhances cost-effectiveness by reducing the overall component count and board size.

Digital PCB Design Considerations

1. Signal Integrity

Maintaining signal integrity is a critical aspect of digital PCB design. As digital signals traverse through the circuit, they can be susceptible to various issues such as crosstalk, reflections, and ground bounce. To mitigate these problems, designers must carefully consider factors like trace routing, impedance matching, and proper termination techniques. By adhering to best practices in signal integrity design, engineers can ensure reliable and error-free transmission of digital data.

2. Power Distribution

Proper power distribution is essential for the stable operation of digital circuits. Digital components require clean and stable power supplies to function accurately. PCB designers must incorporate robust power distribution networks, including appropriate decoupling capacitors, power planes, and ground planes. These measures help reduce voltage fluctuations, minimize noise, and prevent power-related glitches that can disrupt digital signal integrity.

3. Electromagnetic Compatibility (EMC)

Digital PCBs must comply with electromagnetic compatibility (EMC) regulations to minimize electromagnetic interference (EMI) emissions and ensure immunity to external EMI sources. Designers employ various techniques to achieve EMC compliance, such as proper grounding, shielding, and the use of filters and suppression components. By adhering to EMC guidelines, digital PCBs can coexist harmoniously with other electronic devices and avoid interference issues.

4. Thermal Management

As digital circuits operate at high speeds and densities, they generate significant amounts of heat. Efficient thermal management is crucial to prevent overheating and ensure reliable operation. PCB designers incorporate thermal management techniques such as the use of heatsinks, thermal vias, and proper component placement to dissipate heat effectively. Adequate airflow and cooling mechanisms are also considered to maintain optimal operating temperatures.

Applications of Digital PCBs

Digital PCBs find applications across a wide range of industries and domains. Some notable areas where digital PCBs are extensively used include:

-

Consumer Electronics: Digital PCBs are the backbone of modern consumer electronic devices such as smartphones, tablets, laptops, and smart home appliances. These boards enable the processing, storage, and communication capabilities that make these devices indispensable in our daily lives.

-

Automotive Industry: Digital PCBs play a vital role in the automotive sector, powering various electronic systems such as engine control units (ECUs), infotainment systems, and advanced driver assistance systems (ADAS). The reliability and robustness of digital PCBs are critical for ensuring the safety and performance of vehicles.

-

Industrial Automation: Digital PCBs are extensively used in industrial automation systems, including programmable logic controllers (PLCs), human-machine interfaces (HMIs), and sensor networks. These boards enable precise control, monitoring, and communication in manufacturing processes, leading to increased efficiency and productivity.

-

Medical Devices: Digital PCBs are essential components in medical devices such as patient monitors, diagnostic equipment, and imaging systems. The accuracy, reliability, and real-time processing capabilities of digital PCBs are crucial for delivering effective healthcare solutions and ensuring patient safety.

-

Aerospace and Defense: Digital PCBs find applications in aerospace and defense systems, including avionics, radar systems, and satellite communications. These boards must meet stringent requirements for reliability, ruggedness, and performance to withstand extreme environmental conditions and ensure mission-critical operations.

Future Trends in Digital PCB Technology

As technology continues to advance, digital PCBs are expected to evolve and adapt to meet the growing demands of the electronics industry. Some of the future trends in digital PCB technology include:

1. High-Speed Interfaces

The demand for faster data transmission rates is driving the development of high-speed interfaces such as USB 4.0, PCIe 5.0, and Thunderbolt 4. Digital PCBs will need to incorporate advanced signal integrity techniques and high-speed materials to support these interfaces and ensure reliable communication at ultra-high bandwidths.

2. Miniaturization and High Density

The trend towards miniaturization and high-density packaging will continue to shape the design of digital PCBs. Advanced manufacturing techniques like 3D printing, embedded components, and multi-layer stackups will enable the creation of more compact and densely populated boards. This miniaturization will allow for the development of smaller, more powerful electronic devices.

3. Artificial Intelligence (AI) Integration

The integration of artificial intelligence (AI) capabilities into digital PCBs is expected to gain momentum. AI-enabled PCBs will incorporate dedicated hardware accelerators, such as neural processing units (NPUs) and vision processing units (VPUs), to perform complex AI tasks efficiently. These intelligent PCBs will find applications in areas like autonomous vehicles, robotics, and edge computing.

4. Sustainable and Eco-Friendly Materials

As environmental concerns continue to grow, there will be an increased focus on the use of sustainable and eco-friendly materials in digital PCB manufacturing. Bio-based substrates, recyclable materials, and low-impact manufacturing processes will gain traction to reduce the environmental footprint of electronic products. PCB designers and manufacturers will need to adapt to these sustainable practices while maintaining the performance and reliability of digital circuits.

Frequently Asked Questions (FAQ)

-

What is the difference between a digital PCB and an analog PCB?

A digital PCB is designed to handle binary digital signals, which operate with discrete voltage levels representing logical “0” and “1” states. In contrast, an analog PCB deals with continuous signals that can take on any value within a specified range. Digital PCBs are optimized for processing and transmitting digital data, while analog PCBs are suitable for handling analog signals like audio, video, and sensor data. -

What are the key considerations when designing a digital PCB?

When designing a digital PCB, several key considerations must be taken into account. These include maintaining signal integrity by properly routing traces, matching impedances, and using appropriate termination techniques. Power distribution is another critical aspect, ensuring clean and stable power supplies to digital components. Electromagnetic compatibility (EMC) compliance and thermal management are also essential considerations to minimize interference and prevent overheating. -

How do digital PCBs contribute to the functionality of modern electronic devices?

Digital PCBs are the foundation of modern electronic devices, enabling their processing, storage, and communication capabilities. They house the microprocessors, memory devices, and other digital components that allow devices like smartphones, laptops, and smart appliances to perform complex tasks and interact with users seamlessly. Digital PCBs also play a crucial role in industries such as automotive, industrial automation, medical devices, and aerospace, powering various electronic systems and ensuring their reliable operation. -

What are some future trends in digital PCB technology?

The future of digital PCB technology is driven by the demand for faster data transmission rates, miniaturization, and advanced capabilities. High-speed interfaces like USB 4.0 and PCIe 5.0 will require digital PCBs to incorporate advanced signal integrity techniques. The trend towards miniaturization will lead to more compact and densely populated boards using techniques like 3D printing and embedded components. The integration of artificial intelligence (AI) capabilities into digital PCBs is also expected to gain momentum, enabling intelligent devices and edge computing applications. -

How can digital PCBs be designed to be more environmentally friendly?

To design digital PCBs that are more environmentally friendly, there is a growing focus on the use of sustainable and eco-friendly materials. Bio-based substrates and recyclable materials are being explored as alternatives to traditional PCB materials. Low-impact manufacturing processes, such as those that reduce energy consumption and minimize waste, are also being adopted. PCB designers and manufacturers are increasingly considering the environmental impact of electronic products and striving to develop sustainable practices while maintaining the performance and reliability of digital circuits.

Conclusion

Digital PCBs have revolutionized the electronics industry by enabling the efficient processing and transmission of binary digital signals. These modern circuits offer numerous advantages, including high-speed processing, noise immunity, scalability, and cost-effectiveness. However, designing digital PCBs requires careful consideration of signal integrity, power distribution, electromagnetic compatibility, and thermal management.

The applications of digital PCBs span across various industries, from consumer electronics and automotive to industrial automation and medical devices. As technology advances, digital PCBs are expected to evolve, incorporating high-speed interfaces, miniaturization techniques, AI capabilities, and sustainable materials.

By understanding the fundamentals of digital PCBs and staying updated with the latest trends and best practices, engineers and designers can create innovative and reliable electronic products that meet the ever-growing demands of the digital age. As we move forward, digital PCBs will continue to play a pivotal role in shaping the future of electronics and enabling the development of cutting-edge technologies that transform our lives.

| Component | Function |

|---|---|

| Microprocessor/Controller | Executes instructions and processes data |

| Memory Devices | Store data and programs (e.g., RAM, ROM) |

| Logic Gates | Perform logical operations (AND, OR, NOT, XOR) |

| Flip-Flops and Registers | Store and synchronize data within the circuit |

| Oscillators and Clocks | Provide timing signals to synchronize circuit operation |

Table 1: Key components of a digital PCB and their functions.

No responses yet