What is Micro-Sectioning?

Micro-sectioning is the process of cutting a small, representative piece of a material into an extremely thin slice, typically between 20 and 30 micrometers (μm) thick. These thin sections are then mounted on glass slides and polished to a smooth, transparent finish, allowing them to be examined under a microscope using transmitted light.

The primary goal of micro-sectioning is to reveal the internal structure and composition of a material while maintaining its original features and relationships. This technique is essential for understanding the properties, formation processes, and behavior of various materials across different disciplines.

Applications of Micro-Sectioning

Micro-sectioning is widely used in several fields, including:

-

Geology and Earth Sciences: Micro-sectioning is used to study the mineralogy, texture, and structure of rocks, minerals, and sediments. This technique helps geologists understand the formation and alteration processes of Earth’s crust, as well as the history of geological events.

-

Materials Science and Engineering: Micro-sectioning is employed to analyze the microstructure, composition, and properties of various engineered materials, such as metals, alloys, ceramics, and composites. This information is crucial for developing new materials, optimizing manufacturing processes, and investigating material failures.

-

Biology and Life Sciences: Micro-sectioning is used to prepare thin sections of biological tissues, such as plants and animals, for histological analysis. This technique allows researchers to study the structure and function of cells, tissues, and organs, as well as to diagnose diseases and develop new treatments.

-

Archaeology and Cultural Heritage: Micro-sectioning is applied to the study of archaeological artifacts, such as pottery, bones, and paintings, to understand their composition, manufacturing techniques, and preservation state. This information helps archaeologists reconstruct past human activities and cultural practices.

The Micro-Sectioning Process

The micro-sectioning process involves several steps, each requiring specific equipment, materials, and techniques. The following sections will guide you through the preparation of high-quality thin sections.

Equipment and Materials

To perform micro-sectioning, you will need the following equipment and materials:

- Low-speed diamond saw or precision cutting machine

- Grinding and polishing equipment (e.g., grinder/polisher, abrasive papers, polishing cloths)

- Mounting materials (e.g., epoxy resin, hardener, mounting cups)

- Glass slides and cover slips

- Optical microscope with transmitted light capabilities

- Safety equipment (e.g., safety glasses, gloves, dust mask)

Step 1: Sample Selection and Preparation

-

Select a representative sample of the material you wish to study. The sample should be small enough to fit on a glass slide (typically around 2 × 3 cm) and have a relatively flat surface.

-

If the sample is too large or irregularly shaped, use a low-speed diamond saw or precision cutting machine to trim it down to size. Make sure to wear safety glasses and a dust mask during this process.

-

Clean the sample thoroughly with water and a soft brush to remove any dirt, debris, or cutting residue.

Step 2: Mounting the Sample

-

Mix the epoxy resin and hardener according to the manufacturer’s instructions. Pour the mixture into a mounting cup, filling it about halfway.

-

Place the sample into the mounting cup, ensuring that the surface you want to section is facing downwards. Gently press the sample to remove any air bubbles trapped beneath it.

-

Allow the epoxy to cure according to the manufacturer’s instructions, typically overnight at room temperature or for a few hours at an elevated temperature.

Step 3: Cutting and Grinding

-

Once the epoxy has cured, remove the mounted sample from the cup. Use a low-speed diamond saw or precision cutting machine to cut a thin slice (around 1-2 mm thick) from the sample, perpendicular to the surface of interest.

-

Place the cut section on a glass slide, with the surface of interest facing upwards. Apply a small amount of epoxy to the back of the section and the glass slide to secure it in place.

-

Allow the epoxy to cure according to the manufacturer’s instructions.

-

Using progressively finer abrasive papers (e.g., 400, 600, 800, 1200 grit), grind the section down to a thickness of around 50-100 μm. Make sure to keep the section flat and even during grinding.

Step 4: Polishing

-

Switch to a polishing cloth and use progressively finer polishing compounds (e.g., 6 μm, 3 μm, 1 μm diamond paste) to polish the section to a smooth, scratch-free finish.

-

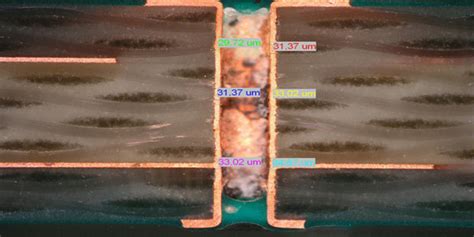

Continue polishing until the section reaches the desired thickness, typically between 20 and 30 μm.

-

Clean the polished section with water and a soft brush to remove any polishing residue.

Step 5: Microscopic Analysis

-

Place a cover slip on top of the polished section, using a small amount of mounting medium (e.g., Canada balsam) to secure it in place.

-

Allow the mounting medium to dry according to the manufacturer’s instructions.

-

Place the prepared thin section under an optical microscope with transmitted light capabilities.

-

Adjust the focus and illumination to obtain a clear image of the section.

-

Analyze the internal structure, composition, and features of the material, taking notes and capturing images as needed.

Tips for Successful Micro-Sectioning

-

Practice makes perfect: Micro-sectioning is a skill that requires practice and patience. Don’t be discouraged if your first few attempts are not perfect; keep practicing, and you will improve over time.

-

Maintain a clean workspace: Keeping your work area clean and organized will help prevent contamination and ensure high-quality results.

-

Use appropriate safety equipment: Always wear safety glasses, gloves, and a dust mask when working with cutting, grinding, and polishing equipment to protect yourself from debris and harmful particles.

-

Take your time: Rushing through the micro-sectioning process can lead to uneven or damaged sections. Take your time and be patient during each step to ensure the best possible results.

-

Experiment with different techniques: As you gain experience with micro-sectioning, don’t be afraid to experiment with different techniques, materials, and equipment to find what works best for your specific samples and research needs.

Frequently Asked Questions (FAQ)

-

What is the ideal thickness for a micro-section?

The ideal thickness for a micro-section depends on the material and the purpose of the analysis, but it typically ranges between 20 and 30 μm. Thinner sections allow for better light transmission and higher resolution imaging, but they may be more challenging to prepare and handle. -

Can I reuse a glass slide for multiple micro-sections?

While it is possible to reuse glass slides, it is generally not recommended. Reusing slides can lead to contamination and may affect the quality of your results. It is best to use a new, clean glass slide for each micro-section. -

How do I know when I’ve reached the desired thickness during grinding and polishing?

Monitoring the thickness of your micro-section during grinding and polishing can be challenging. One method is to use a micrometer to measure the thickness of the section periodically. Another technique is to observe the color and transparency of the section under a microscope; as the section becomes thinner, it will become more transparent and allow more light to pass through. -

What should I do if my micro-section breaks or cracks during preparation?

If your micro-section breaks or cracks during preparation, you may need to start over with a new sample. However, if the damage is minor and does not affect the area of interest, you may be able to salvage the section by carefully re-mounting it on a new glass slide and continuing the grinding and polishing process. -

Can I prepare micro-sections of any material?

While micro-sectioning can be used to prepare thin sections of a wide range of materials, some materials may be more challenging to work with than others. Very hard, brittle, or porous materials, for example, may require specialized equipment or techniques. It is essential to research the specific properties and characteristics of your material before attempting to prepare a micro-section.

Micro-sectioning is a powerful technique for revealing the internal structure and composition of various materials, from rocks and minerals to biological tissues and engineered materials. By following the steps outlined in this guide and practicing regularly, you can master the art of preparing high-quality thin sections for microscopic analysis. As you gain experience, don’t be afraid to experiment with different techniques and adapt the process to suit your specific research needs. With patience, skill, and attention to detail, micro-sectioning can provide invaluable insights into the fascinating world of materials science, geology, biology, and beyond.

| Step | Description | Equipment/Materials |

|---|---|---|

| 1 | Sample Selection and Preparation | Low-speed diamond saw or precision cutting machine, safety glasses, dust mask, water, soft brush |

| 2 | Mounting the Sample | Epoxy resin, hardener, mounting cups |

| 3 | Cutting and Grinding | Low-speed diamond saw or precision cutting machine, glass slides, epoxy, abrasive papers (400, 600, 800, 1200 grit) |

| 4 | Polishing | Polishing cloth, polishing compounds (6 μm, 3 μm, 1 μm diamond paste), water, soft brush |

| 5 | Microscopic Analysis | Optical microscope with transmitted light capabilities, cover slips, mounting medium (e.g., Canada balsam) |

No responses yet