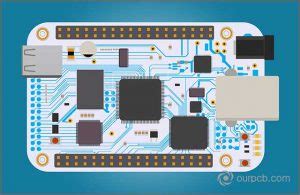

What is PCB Programming?

PCB programming, also known as IC programming or device programming, is the process of loading software, firmware, or data into the memory of an integrated circuit (IC) on a printed circuit board (PCB). This process is essential to ensure that the ICs function correctly and perform their intended tasks within the electronic device.

Why is PCB Programming Important?

PCB programming is important for several reasons:

-

Functionality: Programming the ICs on a PCB ensures that they function as designed and intended. Without proper programming, the electronic device may not work correctly or at all.

-

Customization: PCB programming allows for customization of the device’s functionality. By modifying the software or firmware, developers can add new features, improve performance, or fix bugs.

-

Cost-effectiveness: Programming the ICs on a PCB during the manufacturing process is more cost-effective than programming them individually after assembly. This approach saves time and reduces the risk of errors.

-

Quality control: PCB programming is a critical step in quality control. By testing the programmed ICs, manufacturers can ensure that the electronic device meets the required specifications and functions correctly.

7 Methods of IC Programming in PCBA Processing

There are various methods of IC programming in PCBA processing, each with its own advantages and disadvantages. Here are seven common methods:

1. In-System Programming (ISP)

In-System Programming (ISP) is a method of programming ICs directly on the PCB using a special programming interface. This method allows for programming and reprogramming of the ICs without removing them from the PCB.

Advantages:

– Convenient and fast programming

– Allows for easy updates and modifications

– Reduces the risk of damage to the ICs

Disadvantages:

– Requires a special programming interface

– May not be suitable for high-volume production

2. In-Circuit Serial Programming (ICSP)

In-Circuit Serial Programming (ICSP) is similar to ISP but uses a serial interface to program the ICs. This method is commonly used for programming microcontrollers and other devices with a serial programming interface.

Advantages:

– Simple and cost-effective

– Allows for programming and debugging on the PCB

– Supports a wide range of devices

Disadvantages:

– Slower programming speed compared to other methods

– Requires a dedicated programming header on the PCB

3. JTAG Programming

JTAG (Joint Test Action Group) programming is a standardized method for testing and programming ICs on a PCB. It uses a special interface called the JTAG port to access and manipulate the ICs’ internal registers and memory.

Advantages:

– Standardized and widely supported

– Allows for advanced debugging and testing capabilities

– Supports boundary scan testing

Disadvantages:

– Requires a JTAG-compatible device and interface

– May require additional hardware and software tools

4. Boundary Scan Programming

Boundary Scan programming is an extension of JTAG programming that allows for testing and programming of ICs at the boundary level. This method is useful for detecting manufacturing defects and ensuring the integrity of the connections between ICs.

Advantages:

– Enables thorough testing of the PCB and its components

– Helps identify manufacturing defects and connectivity issues

– Supports programming and testing of high-density PCBs

Disadvantages:

– Requires specialized hardware and software tools

– May not be suitable for all types of ICs

5. Universal Serial Bus (USB) Programming

USB programming involves using a USB interface to program the ICs on a PCB. This method is convenient and fast, as USB ports are widely available on modern computers.

Advantages:

– Fast and convenient programming

– Uses a standard USB interface

– Supports a wide range of devices

Disadvantages:

– Requires a USB programming interface on the PCB

– May not be suitable for high-volume production

6. Secure Digital (SD) Card Programming

SD card programming involves storing the firmware or software on an SD card and using it to program the ICs on the PCB. This method is useful for devices that require frequent updates or have limited storage capacity.

Advantages:

– Allows for easy updates and distribution of firmware

– Suitable for devices with limited storage capacity

– Cost-effective and convenient

Disadvantages:

– Requires an SD card slot on the PCB

– May not be suitable for high-volume production

7. Wireless Programming

Wireless programming involves programming the ICs on a PCB using a wireless interface, such as Bluetooth or Wi-Fi. This method is useful for devices that are difficult to access physically or require remote updates.

Advantages:

– Allows for remote programming and updates

– Convenient for hard-to-reach devices

– Supports over-the-air (OTA) updates

Disadvantages:

– Requires a wireless interface on the PCB

– May be subject to security risks and interference

Choosing the Right PCB Programming Method

When choosing a PCB programming method, consider the following factors:

-

Device requirements: Consider the type of ICs being programmed, their programming interfaces, and the required programming speed and volume.

-

Cost: Evaluate the cost of the programming equipment, software, and labor required for each method.

-

Scalability: Consider the scalability of the programming method for high-volume production and future upgrades.

-

Reliability: Assess the reliability and accuracy of the programming method, as well as its susceptibility to errors and damage.

-

Accessibility: Determine the accessibility of the programming interface on the PCB and the ease of programming and debugging.

PCB Programming Best Practices

To ensure successful PCB programming, follow these best practices:

-

Design for programmability: Incorporate programming interfaces and headers into the PCB design to facilitate easy programming and debugging.

-

Use reliable programming equipment: Invest in high-quality programming equipment and software to ensure accurate and reliable programming.

-

Verify the programming: Test and verify the programmed ICs to ensure they function correctly and meet the required specifications.

-

Document the programming process: Maintain accurate documentation of the programming process, including the software versions, programming parameters, and any modifications made.

-

Implement version control: Use version control systems to track changes to the firmware or software and ensure consistency across different production runs.

Frequently Asked Questions (FAQ)

-

What is the difference between programming and flashing?

Programming and flashing are often used interchangeably, but they refer to slightly different processes. Programming involves loading software, firmware, or data into the memory of an IC, while flashing specifically refers to the process of writing data to flash memory. -

Can all ICs on a PCB be programmed using the same method?

Not necessarily. Different ICs may have different programming interfaces and requirements. It’s important to choose a programming method that is compatible with the specific ICs being programmed. -

How long does PCB programming take?

The duration of PCB programming depends on several factors, such as the size of the firmware or software, the programming method used, and the number of ICs being programmed. In general, programming can take anywhere from a few seconds to several minutes per PCB. -

Can PCB programming be outsourced?

Yes, PCB programming can be outsourced to specialized programming service providers. This can be a cost-effective solution for companies that do not have in-house programming capabilities or require high-volume programming. -

What are the risks associated with PCB programming?

The main risks associated with PCB programming include incorrect programming, damage to the ICs or PCB due to improper handling, and security vulnerabilities if the programming process is not properly secured. It’s important to follow best practices and use reliable equipment to mitigate these risks.

Conclusion

PCB programming is a critical step in the PCBA process that ensures the functionality and performance of electronic devices. By understanding the different methods of IC programming and their advantages and disadvantages, manufacturers can choose the most suitable approach for their specific requirements. Implementing best practices and using reliable equipment can help ensure successful and efficient PCB programming.

| Method | Advantages | Disadvantages |

|---|---|---|

| In-System Programming (ISP) | Convenient and fast, allows for easy updates | Requires special interface, may not suit high-volume |

| In-Circuit Serial Programming (ICSP) | Simple and cost-effective, supports wide range | Slower speed, requires dedicated header |

| JTAG Programming | Standardized, advanced debugging, supports boundary scan | Requires compatible device and interface, may need additional tools |

| Boundary Scan Programming | Thorough testing, identifies defects, supports high-density | Requires specialized tools, may not suit all ICs |

| Universal Serial Bus (USB) Programming | Fast and convenient, uses standard USB | Requires USB interface on PCB, may not suit high-volume |

| Secure Digital (SD) Card Programming | Easy updates, suitable for limited storage, cost-effective | Requires SD card slot on PCB, may not suit high-volume |

| Wireless Programming | Allows remote programming, convenient for hard-to-reach | Requires wireless interface, subject to security risks |

By carefully considering the requirements of their devices and the available programming methods, manufacturers can optimize their PCB programming process and ensure the production of high-quality, reliable electronic products.

No responses yet