Introduction to Sensor Circuits

Sensor circuits are essential components in modern electronic systems, enabling the detection and measurement of various physical quantities such as temperature, pressure, light, and motion. These circuits play a crucial role in a wide range of applications, from industrial automation and environmental monitoring to consumer electronics and medical devices. In this comprehensive guide, we will explore the fundamentals of sensor circuits, their types, and their applications.

What are Sensor Circuits?

Sensor circuits are electronic circuits designed to interface with sensors and convert the measured physical quantities into electrical signals that can be processed by other electronic components or systems. These circuits typically consist of a sensor element, signal conditioning circuitry, and an output stage.

Key Components of Sensor Circuits

-

Sensor Element: The sensor element is the core component of a sensor circuit, responsible for detecting and responding to the physical quantity being measured. Examples include thermistors for temperature sensing, strain gauges for pressure sensing, and photodiodes for light sensing.

-

Signal Conditioning Circuitry: Signal conditioning circuitry is used to amplify, filter, and convert the sensor’s output into a suitable electrical signal for further processing. This may include amplifiers, filters, analog-to-digital converters (ADCs), and other signal processing components.

-

Output Stage: The output stage of a sensor circuit provides the interface between the sensor and the rest of the electronic system. This can be in the form of an analog voltage or current signal, a digital signal, or a wireless transmission.

Types of Sensor Circuits

Temperature Sensor Circuits

Temperature sensor circuits are used to measure and monitor temperature in various applications, such as HVAC systems, industrial processes, and consumer appliances. Common types of temperature sensors include:

-

Thermistors: Thermistors are temperature-sensitive resistors whose resistance changes with temperature. They are widely used in temperature sensing applications due to their high sensitivity and low cost.

-

RTDs (Resistance Temperature Detectors): RTDs are precision temperature sensors that exploit the predictable change in electrical resistance of certain materials, such as platinum or copper, with temperature.

-

Thermocouples: Thermocouples consist of two dissimilar metals joined together, creating a voltage that varies with temperature. They are commonly used in high-temperature applications, such as industrial furnaces and gas turbines.

Example: Thermistor Temperature Sensor Circuit

A simple thermistor temperature sensor circuit can be constructed using a voltage divider configuration, as shown in the table below:

| Component | Value |

|---|---|

| Thermistor | 10 kΩ @ 25°C |

| Resistor | 10 kΩ |

| Voltage Supply | 5 V |

The output voltage of the circuit varies with the thermistor’s resistance, which changes with temperature. This voltage can be measured using an ADC and converted to a temperature reading using the thermistor’s characteristic equation.

Pressure Sensor Circuits

Pressure sensor circuits are designed to measure and monitor pressure in various applications, such as automotive systems, industrial processes, and medical devices. Common types of pressure sensors include:

-

Piezoresistive Pressure Sensors: Piezoresistive pressure sensors rely on the change in resistance of a piezoresistive material, such as silicon, when subjected to pressure. They are widely used in automotive and industrial applications.

-

Capacitive Pressure Sensors: Capacitive pressure sensors consist of a diaphragm and a fixed plate, forming a variable capacitor. As pressure is applied, the diaphragm deforms, changing the capacitance, which can be measured and converted to a pressure reading.

-

Piezoelectric Pressure Sensors: Piezoelectric pressure sensors generate an electrical charge when subjected to pressure. They are commonly used in dynamic pressure measurement applications, such as engine combustion analysis and blast detection.

Example: Piezoresistive Pressure Sensor Circuit

A piezoresistive pressure sensor can be integrated into a Wheatstone bridge circuit, as shown in the table below:

| Component | Value |

|---|---|

| Piezoresistive Sensor | 5 kΩ @ 0 PSI |

| Resistors (R1, R2, R3) | 5 kΩ |

| Voltage Supply | 5 V |

The output voltage of the Wheatstone bridge varies with the resistance of the piezoresistive sensor, which changes with applied pressure. This voltage can be amplified using an instrumentation amplifier and then measured using an ADC for further processing.

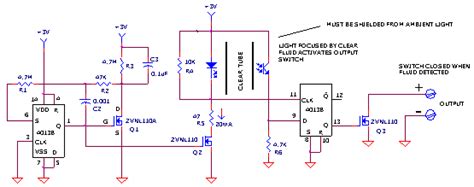

Light Sensor Circuits

Light sensor circuits are used to detect and measure light intensity in various applications, such as ambient light sensing, optical communication, and image sensors. Common types of light sensors include:

-

Photoresistors (LDRs): Photoresistors are light-sensitive resistors whose resistance decreases with increasing light intensity. They are commonly used in ambient light sensing applications, such as automatic lighting control.

-

Photodiodes: Photodiodes are semiconductor devices that generate a current proportional to the incident light intensity. They are widely used in optical communication, barcode readers, and light meters.

-

Phototransistors: Phototransistors are light-sensitive transistors that combine a photodiode and a bipolar transistor in a single package. They offer higher sensitivity and faster response times compared to photoresistors.

Example: Photodiode Light Sensor Circuit

A simple photodiode light sensor circuit can be constructed using a transimpedance amplifier configuration, as shown in the table below:

| Component | Value |

|---|---|

| Photodiode | BPW34 |

| Feedback Resistor | 1 MΩ |

| Op-Amp | LM358 |

| Voltage Supply | 5 V |

The photodiode generates a current proportional to the incident light intensity, which is converted to a voltage by the transimpedance amplifier. The output voltage can be measured using an ADC for further processing.

Signal Conditioning in Sensor Circuits

Signal conditioning is a crucial aspect of sensor circuits, as it ensures that the sensor’s output is compatible with the rest of the electronic system. Common signal conditioning techniques include:

-

Amplification: Amplifiers are used to increase the magnitude of the sensor’s output signal, improving the signal-to-noise ratio and making it easier to process.

-

Filtering: Filters are employed to remove unwanted noise and interference from the sensor’s output signal, improving the overall signal quality.

-

Analog-to-Digital Conversion: ADCs are used to convert the analog output of the sensor into a digital signal that can be processed by digital systems, such as microcontrollers or computers.

-

Linearization: Some sensors exhibit non-linear output characteristics, requiring linearization techniques to improve the accuracy of the measurement. This can be achieved through hardware or software-based approaches.

Applications of Sensor Circuits

Sensor circuits find applications in a wide range of industries and domains, including:

-

Industrial Automation: Sensor circuits are extensively used in industrial automation for process control, quality monitoring, and predictive maintenance.

-

Environmental Monitoring: Sensor circuits are employed in environmental monitoring systems to measure and track various parameters, such as air quality, water quality, and weather conditions.

-

Automotive: Sensor circuits are crucial components in modern vehicles, enabling features such as engine management, safety systems, and advanced driver assistance systems (ADAS).

-

Consumer Electronics: Sensor circuits are integral to many consumer electronic devices, such as smartphones, wearables, and smart home appliances, enabling features like motion tracking, ambient light sensing, and touch sensing.

-

Medical Devices: Sensor circuits are used in various medical devices, such as patient monitoring systems, diagnostic equipment, and implantable devices, to measure and monitor vital signs and other physiological parameters.

Frequently Asked Questions (FAQ)

- What is the difference between active and passive sensors?

-

Active sensors require an external power source to operate and actively emit energy to detect the measured quantity, such as ultrasonic sensors and radar. Passive sensors, on the other hand, do not require an external power source and rely on the energy of the measured quantity itself, such as thermistors and photodiodes.

-

How do I choose the right sensor for my application?

-

When selecting a sensor for your application, consider factors such as the measurement range, accuracy, resolution, response time, environmental conditions, and compatibility with your signal conditioning circuitry. Consult sensor datasheets and application notes to determine the most suitable sensor for your specific requirements.

-

What is the role of an ADC in sensor circuits?

-

An analog-to-digital converter (ADC) is used to convert the analog output of a sensor into a digital signal that can be processed by digital systems, such as microcontrollers or computers. The ADC’s resolution, sampling rate, and accuracy should be chosen based on the sensor’s output characteristics and the application’s requirements.

-

How can I improve the accuracy of my sensor measurements?

-

To improve the accuracy of sensor measurements, consider implementing techniques such as calibration, signal averaging, and sensor fusion. Calibration involves comparing the sensor’s output to a known reference and adjusting the sensor or signal conditioning circuitry accordingly. Signal averaging helps reduce the impact of noise by taking multiple measurements and calculating the average value. Sensor fusion combines data from multiple sensors to provide a more accurate and reliable measurement.

-

What is the importance of signal conditioning in sensor circuits?

- Signal conditioning is crucial in sensor circuits as it ensures that the sensor’s output is compatible with the rest of the electronic system. It helps improve the signal-to-noise ratio, remove unwanted noise and interference, and convert the sensor’s output into a suitable format for further processing. Proper signal conditioning techniques enhance the accuracy, reliability, and performance of the overall sensor system.

Conclusion

Sensor circuits are indispensable components in modern electronic systems, enabling the detection and measurement of various physical quantities. By understanding the fundamentals of sensor circuits, their types, and signal conditioning techniques, engineers and designers can develop efficient and reliable sensing solutions for a wide range of applications. As technology continues to advance, the importance of sensor circuits will only grow, driving innovation in fields such as the Internet of Things (IoT), autonomous vehicles, and smart cities.

No responses yet