Introduction to PCB Batteries

PCB batteries, or Printed Circuit Board batteries, are small, lightweight, and rechargeable power sources that incorporate a battery protection circuit directly onto the PCB. These innovative batteries are designed to provide a safe and efficient power solution for various electronic devices, such as wearables, IoT devices, and portable electronics. The integration of the protection circuit ensures that the battery operates within safe limits, preventing overcharging, over-discharging, and short-circuiting.

Advantages of PCB Batteries

- Compact size: PCB batteries are designed to be as small as possible, making them ideal for space-constrained applications.

- Lightweight: The integration of the protection circuit onto the PCB reduces the overall weight of the battery.

- Enhanced safety: The built-in protection circuit prevents dangerous conditions, such as overcharging and short-circuiting.

- Improved efficiency: PCB batteries optimize power consumption, extending the battery life of the connected device.

- Customizable: Manufacturers can tailor PCB batteries to meet specific application requirements, such as size, capacity, and voltage.

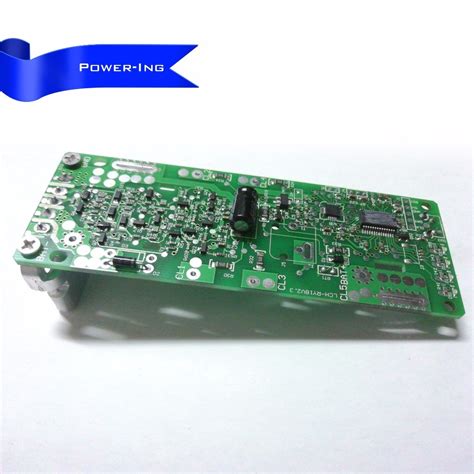

Components of a PCB Battery

A typical PCB battery consists of several key components that work together to provide a safe and efficient power source:

Battery Cell

The battery cell is the core component of a PCB battery, responsible for storing and delivering electrical energy. The most common types of battery cells used in PCB batteries are:

- Lithium-ion (Li-ion): Known for their high energy density and low self-discharge rate, Li-ion cells are widely used in consumer electronics.

- Lithium Polymer (LiPo): LiPo cells offer a higher energy density and a slimmer profile compared to Li-ion cells, making them popular in wearables and portable devices.

Protection Circuit Module (PCM)

The Protection Circuit Module (PCM) is a crucial component of a PCB battery, responsible for monitoring and regulating the battery’s operation. The PCM consists of several sub-components:

- Voltage monitoring: The PCM continuously monitors the battery’s voltage to prevent overcharging and over-discharging.

- Current monitoring: The PCM tracks the current flowing in and out of the battery to detect short-circuits and protect against overcurrent conditions.

- Temperature monitoring: Some PCMs include a temperature sensor to prevent the battery from operating outside its safe temperature range.

Fuel Gauge

A fuel gauge is an optional component that accurately measures the battery’s state of charge (SoC) and provides information about the remaining battery capacity. This information can be communicated to the connected device, allowing it to display the battery level to the user and optimize its power consumption accordingly.

Connectors

PCB batteries typically include connectors that allow them to be easily integrated into the target device. The most common types of connectors used in PCB batteries are:

- JST connectors: JST (Japan Solderless Terminal) connectors are compact, reliable, and widely used in various electronic applications.

- Spring contacts: Some PCB batteries use spring contacts, which provide a secure connection without the need for soldering.

Applications of PCB Batteries

PCB batteries find applications in a wide range of electronic devices, including:

- Wearables: Smartwatches, fitness trackers, and wireless earbuds often rely on PCB batteries for their compact size and lightweight design.

- IoT devices: Wireless sensors, beacons, and other IoT devices use PCB batteries to provide long-lasting, reliable power in space-constrained environments.

- Medical devices: Portable medical devices, such as insulin pumps and continuous glucose monitors, depend on PCB batteries for their safety features and efficient power management.

- Portable electronics: Digital cameras, handheld gaming devices, and portable speakers often incorporate PCB batteries for their compact size and enhanced safety.

Battery Protection Circuit Design Considerations

When designing a battery protection circuit for a PCB battery, several key factors must be considered to ensure optimal performance and safety:

Overcharge Protection

Overcharge protection prevents the battery from being charged beyond its maximum safe voltage, which can lead to reduced battery life, swelling, or even fire. The protection circuit must accurately detect when the battery reaches its maximum voltage and stop the charging process.

Over-discharge Protection

Over-discharge protection prevents the battery from being discharged below its minimum safe voltage, which can cause permanent damage to the battery cell. The protection circuit must detect when the battery reaches its minimum voltage and disconnect the load to prevent further discharge.

Short-circuit Protection

Short-circuit protection safeguards the battery and the connected device from damage caused by a short-circuit condition. The protection circuit must quickly detect a short-circuit and disconnect the battery from the load to prevent high currents from flowing.

Overcurrent Protection

Overcurrent protection prevents excessive current from flowing into or out of the battery, which can cause overheating and damage to the battery or the connected device. The protection circuit must monitor the current and disconnect the battery if the current exceeds a predetermined threshold.

Balancing

In multi-cell battery packs, cell balancing ensures that all cells in the pack have the same voltage, preventing individual cells from being overcharged or over-discharged. The protection circuit must include a balancing mechanism to equalize the voltage across all cells.

Battery Fuel Gauge Integration

Integrating a fuel gauge into a PCB battery provides several benefits, including:

- Accurate state of charge (SoC) estimation: A fuel gauge uses advanced algorithms to accurately estimate the remaining battery capacity, taking into account factors such as temperature, aging, and self-discharge.

- Runtime prediction: By monitoring the battery’s SoC and the connected device’s power consumption, a fuel gauge can predict the remaining runtime, allowing the device to optimize its power management.

- Battery health monitoring: Fuel gauges can track the battery’s health over time, providing information about the number of charge cycles, capacity degradation, and other key metrics.

When selecting a fuel gauge for a PCB battery, designers must consider factors such as accuracy, power consumption, and compatibility with the chosen battery chemistry.

PCB Battery Manufacturing Process

The manufacturing process for PCB batteries involves several key steps:

- PCB design and fabrication: The PCB layout is designed to accommodate the battery cell, protection circuit, and other components. The PCB is then fabricated using standard PCB manufacturing techniques.

- Battery cell selection and testing: The appropriate battery cell is selected based on the application requirements, and each cell is tested to ensure it meets the specified performance and safety criteria.

- PCM assembly: The protection circuit components are soldered onto the PCB, and the circuit is tested to verify its functionality.

- Battery cell integration: The tested battery cell is connected to the PCB, either through soldering or using a connector.

- Final assembly and testing: The completed PCB battery is assembled, and a series of tests are performed to ensure proper functionality, safety, and performance.

Safety and Regulatory Considerations

PCB batteries must comply with various safety and regulatory standards to ensure their safe operation and minimize the risk of accidents. Some of the key standards and regulations include:

- UL 1642: This standard sets forth the requirements for lithium-ion and lithium polymer batteries, covering safety, performance, and labeling aspects.

- IEC 62133: This international standard specifies the safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes.

- UN 38.3: This United Nations standard defines the testing requirements for lithium batteries to ensure their safety during transportation.

- ROHS: The Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electronic and electrical products, including batteries.

Manufacturers must ensure that their PCB batteries comply with all relevant standards and regulations to guarantee their safe and reliable operation.

Future Trends in PCB Battery Technology

As the demand for smaller, safer, and more efficient power sources continues to grow, PCB battery technology is evolving to meet these challenges. Some of the key trends shaping the future of PCB batteries include:

- Increased energy density: Researchers are developing new battery chemistries and materials that offer higher energy densities, enabling smaller batteries with longer runtimes.

- Flexible and stretchable batteries: The development of flexible and stretchable PCB materials allows for the creation of batteries that can conform to various shapes and withstand bending and stretching.

- Wireless charging: The integration of wireless charging capabilities into PCB batteries enables convenient and cable-free charging of connected devices.

- Smart batteries: The incorporation of advanced sensors and communication technologies into PCB batteries enables them to provide real-time data about their health, performance, and environmental conditions.

As these trends continue to evolve, PCB batteries will become increasingly sophisticated, offering enhanced performance, safety, and functionality for a wide range of applications.

Conclusion

PCB batteries represent a significant advancement in battery technology, offering a compact, lightweight, and safe power solution for various electronic devices. By integrating the battery protection circuit directly onto the PCB, these batteries optimize performance, enhance safety, and enable customization to meet specific application requirements.

As the demand for smaller and more efficient power sources continues to grow, PCB battery technology will play an increasingly important role in powering the next generation of electronic devices. With ongoing advancements in battery chemistries, materials, and manufacturing processes, PCB batteries are poised to revolutionize the way we power our devices, enabling new possibilities in wearables, IoT, and portable electronics.

Frequently Asked Questions (FAQ)

-

What is a PCB battery?

A PCB battery is a small, lightweight, and rechargeable battery that incorporates a battery protection circuit directly onto the printed circuit board (PCB). This integration enhances safety, efficiency, and customization options for various electronic applications. -

What are the advantages of using a PCB battery?

PCB batteries offer several advantages, including compact size, lightweight design, enhanced safety features, improved efficiency, and the ability to customize the battery to meet specific application requirements. -

What types of battery cells are commonly used in PCB batteries?

The most common types of battery cells used in PCB batteries are lithium-ion (Li-ion) and lithium polymer (LiPo) cells. Li-ion cells are known for their high energy density and low self-discharge rate, while LiPo cells offer an even higher energy density and a slimmer profile. -

What is the role of the Protection Circuit Module (PCM) in a PCB battery?

The Protection Circuit Module (PCM) is responsible for monitoring and regulating the battery’s operation, ensuring that it stays within safe limits. The PCM continuously monitors the battery’s voltage, current, and sometimes temperature to prevent overcharging, over-discharging, and short-circuiting. -

What safety and regulatory standards do PCB batteries need to comply with?

PCB batteries must comply with various safety and regulatory standards, such as UL 1642 for lithium-ion and lithium polymer batteries, IEC 62133 for portable sealed secondary cells and batteries, UN 38.3 for lithium battery transportation safety, and the RoHS directive for limiting hazardous substances in electronic products.

No responses yet