Introduction to Copper Foil in Flexible Circuits

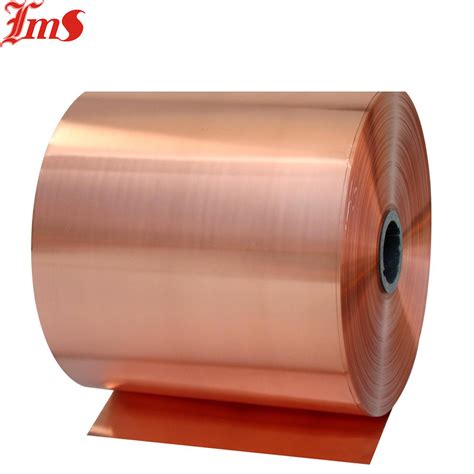

Copper foil is an essential component in the manufacturing of flexible printed Circuit Boards (PCBs). It serves as the conductive layer that allows electrical signals to pass through the circuit. The quality and properties of the copper foil used can significantly impact the performance, reliability, and durability of the flex circuit.

In this article, we will explore two main types of copper foil used in Flex PCBs: Rolled Annealed (RA) Copper and Electrodeposited (ED) Copper. We will compare their properties, manufacturing processes, advantages, and disadvantages to help you make an informed decision when selecting the appropriate copper foil for your flex circuit applications.

What is Rolled Annealed (RA) Copper?

Rolled Annealed (RA) Copper is a type of copper foil produced by rolling high-purity copper ingots into thin sheets and then annealing them to improve their mechanical properties. The annealing process involves heating the rolled copper foil to a specific temperature and then cooling it slowly to relieve internal stresses and increase its ductility.

Manufacturing Process of RA Copper

- Copper ingots are heated and rolled into thin sheets using a rolling mill.

- The rolled copper foil undergoes an annealing process to improve its mechanical properties.

- The annealed copper foil is then cleaned, trimmed, and coated with a protective layer to prevent oxidation.

Properties of RA Copper

- High ductility and flexibility

- Excellent mechanical strength

- Good electrical conductivity

- Uniform thickness and surface finish

- Low residual stresses

Advantages of RA Copper

- Suitable for applications requiring high flexibility and bending endurance

- Ideal for dynamic flex circuits that undergo repeated bending and flexing

- Excellent for high-frequency signal transmission due to its smooth surface

- Offers better thermal management compared to ED Copper

Disadvantages of RA Copper

- Higher cost compared to ED Copper

- Longer lead times due to the complex manufacturing process

- Limited availability in ultra-thin gauges (less than 9 μm)

What is Electrodeposited (ED) Copper?

Electrodeposited (ED) Copper is a type of copper foil produced by electroplating copper onto a rotating drum or a continuous stainless steel belt. The thickness of the ED Copper foil is controlled by the electroplating time and current density.

Manufacturing Process of ED Copper

- A rotating drum or continuous stainless steel belt is immersed in an electrolytic solution containing copper ions.

- An electric current is applied, causing the copper ions to deposit onto the drum or belt surface.

- The deposited copper foil is peeled off the drum or belt, cleaned, and coated with a protective layer.

Properties of ED Copper

- Good electrical conductivity

- Uniform thickness distribution

- Available in ultra-thin gauges (down to 5 μm)

- Lower cost compared to RA Copper

- Faster production times

Advantages of ED Copper

- Cost-effective solution for high-volume production

- Suitable for applications requiring thinner copper foils

- Ideal for static flex circuits with limited bending requirements

- Faster turnaround times due to simpler manufacturing process

Disadvantages of ED Copper

- Lower ductility and flexibility compared to RA Copper

- Higher residual stresses that may affect circuit reliability

- Less suitable for dynamic flex circuits with repeated bending

- May have a slightly rougher surface compared to RA Copper

Comparison of RA Copper and ED Copper

| Property | RA Copper | ED Copper |

|---|---|---|

| Ductility and Flexibility | High | Moderate |

| Mechanical Strength | Excellent | Good |

| Electrical Conductivity | Good | Good |

| Thickness Uniformity | Excellent | Good |

| Surface Finish | Smooth | Slightly rougher |

| Cost | Higher | Lower |

| Production Lead Time | Longer | Shorter |

| Ultra-thin Gauge Availability | Limited (≥9 μm) | Available (≥5 μm) |

Choosing Between RA Copper and ED Copper

When selecting the appropriate copper foil for your flex circuit application, consider the following factors:

- Application requirements: Determine whether your flex circuit will undergo repeated bending (dynamic) or have limited bending requirements (static).

- Thickness requirements: Consider the desired thickness of the copper foil based on your design and electrical requirements.

- Cost and production volume: Evaluate the cost implications and production volume to determine the most cost-effective solution.

- Lead time: Take into account the required lead time for your project and the manufacturing process duration for each type of copper foil.

FAQ

1. Can I use ED Copper for dynamic flex circuits?

While ED Copper can be used for dynamic flex circuits, it may not provide the same level of bending endurance and reliability as RA Copper. RA Copper is generally recommended for applications requiring repeated bending and flexing.

2. Is it possible to achieve ultra-thin copper foils with RA Copper?

RA Copper is available in thicknesses down to 9 μm. For ultra-thin copper foils less than 9 μm, ED Copper is the preferred option, as it can be manufactured in thicknesses as low as 5 μm.

3. How does the cost of RA Copper compare to ED Copper?

RA Copper is generally more expensive than ED Copper due to its complex manufacturing process and superior mechanical properties. However, the cost difference may be justified for applications requiring high flexibility and bending endurance.

4. Which type of copper foil is better for high-frequency applications?

RA Copper is often preferred for high-frequency applications due to its smooth surface finish, which minimizes signal loss and improves Signal Integrity. The smoother surface of RA Copper reduces the skin effect and provides better high-frequency performance compared to ED Copper.

5. Can I use a combination of RA Copper and ED Copper in the same flex circuit?

Yes, it is possible to use both RA Copper and ED Copper in the same flex circuit design. This approach can be beneficial when certain layers require high flexibility (RA Copper) while others can utilize the cost-effectiveness of ED Copper. However, careful design considerations must be made to ensure proper adhesion and compatibility between the two types of copper foil.

Conclusion

Copper foil plays a crucial role in the performance and reliability of flexible printed circuit boards. Understanding the differences between Rolled Annealed (RA) Copper and Electrodeposited (ED) Copper is essential for selecting the appropriate type of copper foil for your specific application.

RA Copper offers superior ductility, flexibility, and bending endurance, making it ideal for dynamic flex circuits that undergo repeated bending and flexing. It also provides excellent mechanical strength, smooth surface finish, and better thermal management compared to ED Copper. However, RA Copper comes at a higher cost and longer lead times due to its complex manufacturing process.

On the other hand, ED Copper is a cost-effective solution for high-volume production and applications requiring thinner copper foils. It offers good electrical conductivity, uniform thickness distribution, and faster production times. However, ED Copper has lower ductility and flexibility compared to RA Copper and may have slightly higher residual stresses.

When choosing between RA Copper and ED Copper, consider your application requirements, thickness needs, cost implications, production volume, and lead time. By carefully evaluating these factors, you can select the most suitable copper foil for your flex circuit design, ensuring optimal performance, reliability, and cost-effectiveness.

No responses yet