Types of PCB Substrate Materials

There are several types of PCB substrate materials available, each with its own unique properties and characteristics. The most common PCB substrate materials include:

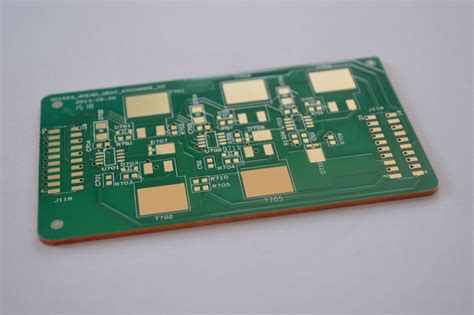

1. FR-4

FR-4 (Flame Retardant 4) is the most widely used PCB substrate material. It is a composite material made of woven fiberglass cloth with an epoxy resin binder. FR-4 offers good mechanical strength, excellent electrical insulation properties, and reasonable thermal stability. It is suitable for a wide range of applications, including consumer electronics, industrial control systems, and telecommunications equipment.

Advantages of FR-4:

- Cost-effective

- Good electrical insulation properties

- Suitable for general-purpose applications

- Widely available

Disadvantages of FR-4:

- Limited high-frequency performance

- Higher dielectric constant compared to some other materials

- Not suitable for extreme temperature environments

2. High-Frequency Laminates

High-frequency laminates are designed for applications that require superior high-frequency performance, such as RF (Radio Frequency) and microwave circuits. These materials have a lower dielectric constant and loss tangent compared to FR-4, which minimizes signal loss and distortion at high frequencies. Some common high-frequency laminates include:

a. Rogers Materials (RO4350B, RO4003C)

- Excellent high-frequency performance

- Low dielectric constant and loss tangent

- Suitable for RF and microwave applications

b. PTFE (Polytetrafluoroethylene) Laminates

- Very low dielectric constant and loss tangent

- Excellent high-frequency performance

- Suitable for high-speed digital and RF applications

3. Metal Core PCBs

Metal core PCBs (MCPCBs) feature a metal substrate, typically aluminum, instead of the traditional FR-4 material. The metal substrate provides excellent thermal conductivity, allowing for efficient heat dissipation from power-intensive components. MCPCBs are commonly used in applications that generate significant amounts of heat, such as LED lighting, power electronics, and automotive electronics.

Advantages of Metal Core PCBs:

- Excellent thermal conductivity

- Improved heat dissipation

- Enhanced mechanical stability

- Suitable for high-power applications

Disadvantages of Metal Core PCBs:

- Higher cost compared to FR-4

- Limited electrical insulation properties

- Requires specialized manufacturing processes

4. Flexible PCBs

Flexible PCBs are made using thin, flexible substrates, such as polyimide or polyester films. These materials allow the PCB to bend and flex without damaging the circuit or components. Flexible PCBs are ideal for applications that require conformity to curved surfaces, space-saving designs, or dynamic flexing during operation.

Advantages of Flexible PCBs:

- Flexibility and conformity to curved surfaces

- Lightweight and space-saving designs

- Improved shock and vibration resistance

- Suitable for wearable electronics and compact devices

Disadvantages of Flexible PCBs:

- Higher cost compared to rigid PCBs

- Limited component mounting options

- Requires specialized design and manufacturing processes

Comparison of PCB Substrate Materials

To help you choose the right PCB substrate material for your YRAYPCB project, we have compiled a comparison table highlighting the key properties of the most common materials:

| Property | FR-4 | High-Frequency Laminates | Metal Core PCBs | Flexible PCBs |

|---|---|---|---|---|

| Dielectric Constant | 4.3-4.7 | 2.2-3.5 | N/A | 3.2-3.5 |

| Loss Tangent | 0.02 | 0.001-0.005 | N/A | 0.002-0.01 |

| Thermal Conductivity (W/mK) | 0.3-0.4 | 0.6-1.0 | 1.0-2.5 | 0.2-0.3 |

| Thermal Expansion (ppm/°C) | 12-16 | 10-20 | 6-10 | 20-40 |

| Flexibility | Rigid | Rigid | Rigid | Flexible |

| Cost | Low | High | Moderate | High |

Factors to Consider When Choosing a PCB Substrate Material

When selecting a PCB substrate material for your YRAYPCB project, consider the following factors:

1. Electrical Requirements

- Dielectric constant and loss tangent for high-frequency applications

- Insulation properties for high-voltage applications

2. Thermal Management

- Thermal conductivity for heat dissipation

- Thermal expansion for reliability in varying temperature environments

3. Mechanical Requirements

- Flexibility for conformity to curved surfaces or dynamic flexing

- Mechanical strength for structural integrity

4. Cost and Availability

- Material and manufacturing costs

- Availability and lead times for the selected material

FAQ

Q1: What is the most common PCB substrate material?

A1: FR-4 is the most widely used PCB substrate material due to its cost-effectiveness, good electrical insulation properties, and suitability for general-purpose applications.

Q2: Which PCB substrate materials are best for high-frequency applications?

A2: High-frequency laminates, such as Rogers materials (RO4350B, RO4003C) and PTFE laminates, are best suited for high-frequency applications due to their low dielectric constant and loss tangent.

Q3: When should I use a metal core PCB?

A3: Metal core PCBs are ideal for applications that generate significant amounts of heat, such as LED lighting, power electronics, and automotive electronics, as they provide excellent thermal conductivity and improved heat dissipation.

Q4: What are the advantages of using flexible PCBs?

A4: Flexible PCBs offer several advantages, including flexibility and conformity to curved surfaces, lightweight and space-saving designs, improved shock and vibration resistance, and suitability for wearable electronics and compact devices.

Q5: How do I choose the right PCB substrate material for my project?

A5: To choose the right PCB substrate material for your project, consider factors such as electrical requirements, thermal management, mechanical requirements, cost, and availability. Consult with YRAYPCB’s experts to discuss your specific needs and determine the best material for your application.

Conclusion

Selecting the right PCB substrate material is crucial for the success of your YRAYPCB project. By understanding the properties and characteristics of different materials, such as FR-4, high-frequency laminates, metal core PCBs, and flexible PCBs, you can make an informed decision based on your specific requirements. Consider factors like electrical performance, thermal management, mechanical properties, and cost when choosing a substrate material.

YRAYPCB offers a wide range of PCB substrate materials and expert guidance to help you select the best option for your project. Our experienced team can assist you in navigating the various material options and provide recommendations based on your unique needs. Whether you are working on a general-purpose application, a high-frequency design, a power-intensive device, or a flexible electronics project, YRAYPCB has the expertise and resources to support you.

Contact YRAYPCB today to discuss your PCB substrate material requirements and take the first step towards creating a successful, reliable, and cost-effective PCB for your application.

No responses yet