Key Components of a BOM list

A typical BOM list includes the following key components:

1. Part Numbers

Each component or part in the BOM list is assigned a unique part number, which serves as a reference for identification and tracking purposes. Part numbers help to avoid confusion and ensure that the correct components are used in the production process.

2. Part Descriptions

Alongside the part number, the BOM list provides a brief description of each component or part. This description should be clear and concise, providing enough information to identify the item without ambiguity.

3. Quantity

The BOM list specifies the quantity of each component or part required to produce a single unit of the finished product. This information is crucial for ensuring that the correct number of components is available during the production process.

4. Unit of Measure

The unit of measure (UOM) indicates the standard unit in which the quantity of each component is expressed. Common units of measure include pieces, meters, kilograms, and liters.

5. Procurement Details

The BOM list may also include information related to the procurement of each component, such as the supplier name, lead time, and cost. This information helps the procurement team to plan and manage the sourcing of components effectively.

Types of BOM Lists

There are several types of BOM lists, each serving a specific purpose in the product development and manufacturing process:

1. Engineering BOM (EBOM)

The Engineering BOM, also known as the Design BOM, is created by the product development team during the design phase. It includes all the components and parts required to build the product as designed, without considering the manufacturing process or supply chain constraints. The EBOM serves as a blueprint for the product and is used to create the Manufacturing BOM.

2. Manufacturing BOM (MBOM)

The Manufacturing BOM is derived from the Engineering BOM and is optimized for the manufacturing process. It takes into account the specific requirements of the production line, such as assembly sequences, machine capabilities, and available components from suppliers. The MBOM may include additional items not found in the EBOM, such as packaging materials or temporary assembly components.

3. Sales BOM (SBOM)

The Sales BOM, also known as the Customer BOM, is a simplified version of the BOM list used by the sales team. It includes only the components and parts that are relevant to the customer, such as customizable options or upgrades. The SBOM helps the sales team to communicate effectively with customers and manage their expectations regarding the product’s features and capabilities.

4. Service BOM (SVBOM)

The Service BOM is used by the after-sales service team to manage the maintenance, repair, and overhaul (MRO) of products. It includes all the components and parts required to service the product throughout its lifecycle, as well as any consumables or wear-and-tear items that may need to be replaced periodically.

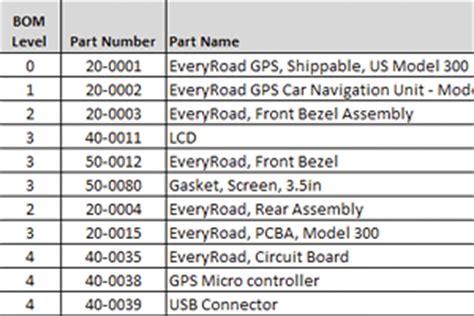

BOM List Hierarchy

A BOM list is typically structured as a hierarchical tree, with the finished product at the top level and the components and parts arranged in levels below. This hierarchical structure helps to visualize the relationships between components and subassemblies, making it easier to understand the product’s structure and assembly process.

Here’s an example of a simplified BOM list hierarchy for a desktop computer:

- Desktop Computer (Level 0)

- Motherboard (Level 1)

- CPU (Level 2)

- RAM (Level 2)

- GPU (Level 2)

- Power Supply (Level 1)

- Hard Drive (Level 1)

- Optical Drive (Level 1)

- Case (Level 1)

- Front Panel (Level 2)

- Side Panel (Level 2)

- Rear Panel (Level 2)

In this example, the desktop computer is the top-level item (Level 0), with components like the motherboard, power supply, and case at Level 1. The motherboard itself is composed of subcomponents, such as the CPU, RAM, and GPU, which are at Level 2 in the hierarchy.

BOM List Formats

BOM lists can be created and maintained in various formats, depending on the organization’s preferences and the tools available. Some common formats include:

1. Spreadsheets

Spreadsheet software, such as Microsoft Excel or Google Sheets, is widely used for creating and managing BOM lists. Spreadsheets offer a simple and flexible way to organize component data, perform calculations, and collaborate with team members.

2. Dedicated BOM Software

There are specialized software solutions designed specifically for creating and managing BOM lists. These tools often provide additional features, such as version control, change management, and integration with other product lifecycle management (PLM) systems.

3. PLM Systems

Product Lifecycle Management (PLM) systems are comprehensive software platforms that manage the entire product lifecycle, from concept to retirement. PLM systems often include built-in BOM management capabilities, allowing teams to create, update, and share BOM lists within the context of the broader product development process.

Best Practices for Creating and Managing BOM Lists

To ensure the effectiveness and accuracy of your BOM lists, consider the following best practices:

1. Standardize Part Numbering

Establish a consistent part numbering scheme to ensure that all components are easily identifiable and trackable. This may involve using a combination of letters, numbers, and symbols to represent different attributes of the component, such as its function, material, or size.

2. Use Clear and Concise Descriptions

Provide clear and concise descriptions for each component in the BOM list. Avoid using ambiguous or overly technical language, and ensure that the descriptions are easily understandable by all team members, including those from non-technical backgrounds.

3. Maintain Accuracy and Completeness

Regularly review and update your BOM lists to ensure that they accurately reflect the current product design and manufacturing process. Encourage team members to report any discrepancies or updates promptly, and establish a process for verifying and incorporating these changes.

4. Implement Version Control

Use version control to track changes to your BOM lists over time. This helps to maintain a clear history of revisions and ensures that all team members are working with the most up-to-date information.

5. Collaborate and Communicate

Foster collaboration and communication among team members involved in the creation and management of BOM lists. Encourage regular meetings or discussions to review BOM status, discuss any issues or concerns, and ensure alignment across different departments or functions.

Common Challenges in BOM List Management

Managing BOM lists can present several challenges, particularly in complex product development environments. Some common challenges include:

1. Ensuring Data Accuracy

Maintaining accurate and up-to-date BOM data can be difficult, especially when dealing with large numbers of components and frequent design changes. Inaccurate BOM data can lead to production delays, cost overruns, and quality issues.

2. Managing Change

As products evolve and requirements change, BOM lists must be updated accordingly. Managing these changes effectively requires a robust change management process, as well as clear communication and collaboration among team members.

3. Integrating with Other Systems

BOM lists often need to be integrated with other systems, such as ERP, MRP, or PLM platforms. Ensuring seamless integration and data synchronization can be challenging, particularly when dealing with legacy systems or disparate data formats.

4. Scaling with Product Complexity

As products become more complex and involve a greater number of components and subassemblies, BOM lists can become increasingly difficult to manage. Ensuring that BOM lists remain accurate, complete, and easily navigable as product complexity increases is a key challenge for many organizations.

Frequently Asked Questions (FAQ)

1. What is the difference between a BOM and a parts list?

A BOM (Bill of Materials) is a comprehensive list of all the components, parts, and materials required to manufacture a product, along with their quantities and relationships. A parts list, on the other hand, is a simpler list of components or parts, often without the detailed hierarchy or assembly information found in a BOM.

2. How do I create a BOM list?

To create a BOM list, follow these steps:

- Break down the product into its constituent components and subassemblies.

- Assign unique part numbers and descriptions to each component.

- Specify the quantity required for each component, along with the unit of measure.

- Organize the components into a hierarchical structure, reflecting the product’s assembly sequence.

- Include any additional information, such as procurement details or reference documents.

3. What is the role of a BOM in the product development process?

A BOM plays a crucial role in the product development process by:

- Serving as a central reference for all components and materials required to build the product

- Enabling effective communication and collaboration among design, engineering, and manufacturing teams

- Facilitating accurate cost estimation and procurement planning

- Supporting the creation of work instructions and assembly documentation

- Providing a basis for product configuration management and change control

4. How often should a BOM list be updated?

A BOM list should be updated whenever there are changes to the product design, components, or manufacturing process. This may include:

- Design revisions or improvements

- Component substitutions or supplier changes

- Manufacturing process optimizations

- Quality or reliability enhancements

It is important to establish a regular review and update process to ensure that BOM lists remain accurate and up-to-date throughout the product lifecycle.

5. What are the benefits of using dedicated BOM management software?

Dedicated BOM management software offers several benefits over traditional spreadsheet-based methods:

- Centralized data storage and version control

- Automated change management and approval workflows

- Integration with other product development and manufacturing systems

- Enhanced collaboration and communication features

- Improved data accuracy and integrity

- Scalability to handle complex product structures and large numbers of components

By leveraging dedicated BOM management software, organizations can streamline their BOM processes, reduce errors and inconsistencies, and ultimately improve product quality and time-to-market.

Conclusion

A well-maintained BOM list is a critical tool for ensuring the success of any product development and manufacturing endeavor. By providing a comprehensive and accurate record of all components, parts, and materials required to build a product, a BOM list enables effective communication, collaboration, and decision-making throughout the product lifecycle.

To maximize the value of your BOM lists, it is important to establish clear processes and best practices for creation, maintenance, and change management. This may involve adopting dedicated BOM management software, implementing robust version control and collaboration features, and fostering a culture of continuous improvement and communication among team members.

By investing in effective BOM list management, organizations can reduce errors, improve product quality, and accelerate time-to-market, ultimately driving greater business success and customer satisfaction.

No responses yet