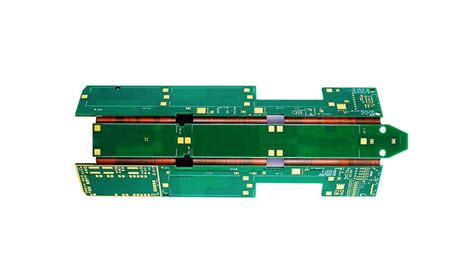

Flex PCB Applications in Consumer Electronics

One of the most prominent areas where Flex PCBs have made a significant impact is consumer electronics. The demand for smaller, thinner, and more feature-packed devices has driven the adoption of Flex PCBs in this sector.

Smartphones and Tablets

Flex PCBs are extensively used in smartphones and tablets, enabling manufacturers to create sleek and compact designs. These circuits can be folded and bent to fit into tight spaces, allowing for the integration of numerous components and features within a small form factor. Flex PCBs are used for connecting displays, cameras, sensors, and other modules in these devices.

Wearable Electronics

The wearable technology market has exploded in recent years, and Flex PCBs have played a crucial role in its growth. Flex circuits are used in smartwatches, fitness trackers, smart clothing, and other wearable devices. Their flexibility and durability make them ideal for applications that require conformity to the human body and resistance to repeated bending and stretching.

Cameras and Imaging Devices

Flex PCBs are commonly used in digital cameras, action cameras, and other imaging devices. They enable the connection of image sensors, lenses, and other components in compact camera modules. Flex circuits also facilitate the integration of advanced features such as image stabilization, autofocus, and zoom functionality.

Flex PCB Applications in Automotive Industry

The automotive industry has embraced Flex PCBs to enhance vehicle performance, safety, and convenience. As vehicles become more connected and electrified, the demand for flexible and reliable circuitry has increased.

Instrument Clusters and Displays

Flex PCBs are used in automotive instrument clusters and displays, enabling the integration of high-resolution graphics, touch functionality, and customizable layouts. These circuits can be shaped to fit the contours of the dashboard, providing a seamless and attractive design.

Advanced Driver Assistance Systems (ADAS)

ADAS technologies, such as collision avoidance, lane departure warning, and adaptive cruise control, rely on Flex PCBs for their implementation. Flex circuits connect sensors, cameras, and radar modules to the vehicle’s electronic control units (ECUs), enabling real-time data processing and decision-making.

Electric and Hybrid Vehicles

Flex PCBs are essential components in electric and hybrid vehicles. They are used in battery management systems, power distribution units, and motor controllers. Flex circuits can withstand the high temperatures and vibrations encountered in these applications, ensuring reliable performance and long-term durability.

Flex PCB Applications in Medical Devices

The medical industry has greatly benefited from the adoption of Flex PCBs, enabling the development of innovative and life-saving devices. Flex circuits offer biocompatibility, miniaturization, and reliability, making them suitable for a wide range of medical applications.

Implantable Devices

Flex PCBs are used in implantable medical devices such as pacemakers, defibrillators, and neurostimulators. These circuits can be designed to conform to the shape of the human body, minimizing discomfort and allowing for long-term implantation. Flex PCBs also enable the integration of sensors, electrodes, and wireless communication modules in these devices.

Diagnostic and Monitoring Equipment

Flex circuits are utilized in various diagnostic and monitoring equipment, including portable ultrasound machines, patient monitors, and wearable health trackers. They enable the miniaturization of these devices, making them more portable and user-friendly. Flex PCBs also facilitate the integration of advanced features such as wireless connectivity and high-resolution displays.

Surgical Instruments

Flex PCBs are incorporated into surgical instruments, such as endoscopes, laparoscopic tools, and robotic systems. They enable the transmission of high-quality images, sensor data, and control signals between the instrument and the external processing unit. Flex circuits also allow for the miniaturization of surgical tools, enabling minimally invasive procedures and faster patient recovery.

Flex PCB Applications in Aerospace and Defense

The aerospace and defense industries have long been early adopters of Flex PCB technology. Flex circuits offer significant advantages in terms of weight reduction, space savings, and reliability, making them ideal for these demanding applications.

Satellite and Space Systems

Flex PCBs are extensively used in satellite and space systems, where weight and space are at a premium. They enable the integration of complex electronics into compact and lightweight packages, reducing launch costs and improving system performance. Flex circuits can withstand the harsh conditions of space, including extreme temperatures, radiation, and vacuum.

Military and Defense Equipment

Flex PCBs are critical components in military and defense equipment, such as communication systems, surveillance devices, and unmanned vehicles. They offer high reliability, ruggedness, and resistance to shock and vibration, ensuring uninterrupted performance in hostile environments. Flex circuits also enable the integration of advanced features, such as encryption and secure Communication Protocols.

Aviation Systems

Flex PCBs are used in various aviation systems, including avionics, in-flight entertainment, and cabin management. They enable the integration of complex electronics into the limited space available in aircraft, reducing weight and improving fuel efficiency. Flex circuits also offer high reliability and resistance to the vibrations and temperature variations encountered in aviation applications.

Flex PCB Applications in Industrial Automation

Industrial automation has greatly benefited from the adoption of Flex PCBs, enabling the development of more efficient, compact, and reliable systems.

Robotics and Automated Systems

Flex PCBs are used in industrial robots and automated systems, enabling the integration of sensors, actuators, and control electronics into compact and flexible packages. They allow for the creation of complex motion control systems, such as multi-axis Robotic Arms and high-speed pick-and-place machines. Flex circuits also offer high reliability and resistance to the harsh environments encountered in industrial settings.

Industrial Sensors and Monitoring Devices

Flex PCBs are utilized in various industrial sensors and monitoring devices, such as temperature probes, pressure sensors, and vibration monitors. They enable the miniaturization of these devices, making them more compact and easier to integrate into existing systems. Flex circuits also offer high reliability and resistance to the extreme conditions encountered in industrial environments.

Flexible Displays and User Interfaces

Flex PCBs are used in industrial flexible displays and user interfaces, enabling the creation of intuitive and user-friendly control systems. They allow for the integration of touch screens, haptic feedback, and customizable layouts, improving operator efficiency and reducing training time. Flex circuits also offer high durability and resistance to the wear and tear encountered in industrial settings.

Flex PCB Applications in Emerging Technologies

Flex PCBs are playing a crucial role in the development of emerging technologies, enabling the creation of innovative and transformative products.

Internet of Things (IoT) Devices

Flex PCBs are used in various IoT devices, such as smart home appliances, industrial sensors, and wearable health monitors. They enable the integration of sensors, wireless communication modules, and power management systems into compact and flexible packages. Flex circuits also offer high reliability and low power consumption, making them ideal for battery-powered IoT devices.

Flexible and Stretchable Electronics

Flex PCBs are at the forefront of flexible and stretchable electronics research, enabling the development of novel applications such as electronic skin, wearable health monitors, and soft robotics. They allow for the creation of circuits that can conform to complex shapes and withstand repeated stretching and bending. Flex PCBs also offer biocompatibility and the ability to integrate various sensors and actuators.

Flexible Displays and User Interfaces

Flex PCBs are used in the development of flexible displays and user interfaces, enabling the creation of bendable and rollable screens for smartphones, tablets, and other devices. They allow for the integration of touch sensors, haptic feedback, and other interactive features into thin and flexible packages. Flex circuits also offer high durability and resistance to repeated bending and folding.

Frequently Asked Questions (FAQ)

1. What are the advantages of using Flex PCBs over traditional rigid PCBs?

Flex PCBs offer several advantages over traditional rigid PCBs, including:

– Flexibility and conformity to complex shapes

– Reduced weight and space savings

– Increased reliability and durability

– Improved signal integrity and reduced electromagnetic interference (EMI)

– Simplified assembly and reduced interconnect complexity

2. What materials are used in the construction of Flex PCBs?

Flex PCBs are typically made from a combination of flexible substrate materials, such as polyimide or polyester, and conductive materials, such as copper or silver. The substrate provides the necessary flexibility and insulation, while the conductive materials form the Circuit Traces and interconnects.

3. Can Flex PCBs be used in high-temperature applications?

Yes, Flex PCBs can be designed to withstand high temperatures, depending on the materials used in their construction. Polyimide-based Flex PCBs, for example, can operate at temperatures up to 200°C, making them suitable for various high-temperature applications, such as automotive and aerospace systems.

4. How do Flex PCBs compare to rigid PCBs in terms of cost?

Flex PCBs are generally more expensive than rigid PCBs due to the specialized materials and manufacturing processes involved. However, the overall cost savings achieved through reduced weight, space savings, and simplified assembly can offset the higher initial cost of Flex PCBs in many applications.

5. What are the challenges associated with designing and manufacturing Flex PCBs?

Designing and manufacturing Flex PCBs presents several challenges, including:

– Ensuring adequate flexibility and durability of the circuit traces and interconnects

– Managing the thermal expansion and contraction of the flexible substrate materials

– Achieving reliable and consistent electrical performance under repeated bending and flexing

– Optimizing the layout and routing of the circuit traces to minimize stress and strain

– Implementing appropriate shielding and grounding strategies to mitigate EMI and signal integrity issues

Conclusion

Flex PCBs have revolutionized the electronics industry, enabling the development of compact, lightweight, and feature-rich devices across various sectors. From consumer electronics and automotive systems to medical devices and aerospace applications, Flex PCBs have proven their versatility and reliability in countless applications.

As technology continues to advance and new challenges emerge, Flex PCBs will undoubtedly play a crucial role in shaping the future of electronics. Their ability to conform to complex shapes, reduce weight and space, and improve system performance makes them an indispensable tool for designers and engineers worldwide.

By understanding the diverse applications and advantages of Flex PCBs, professionals in the electronics industry can leverage this technology to create innovative and transformative products that push the boundaries of what is possible. As we move forward, the continued development and adoption of Flex PCBs will be essential in driving the growth and evolution of the electronics industry.

No responses yet