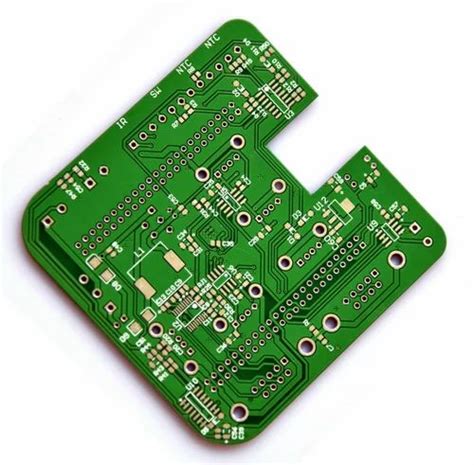

Introduction to RF4 PCBs

RF4 PCBs, also known as high-performance printed circuit boards, are designed to meet the demanding requirements of high-frequency and high-speed applications. These PCBs are made using advanced materials with a high Glass Transition Temperature (Tg), which ensures excellent thermal stability and reliability. RF4 PCBs are commonly used in various industries, including telecommunications, aerospace, military, and medical devices.

What is Tg in PCBs?

Tg, or glass transition temperature, is a critical parameter in PCB manufacturing. It refers to the temperature at which the PCB Material transitions from a rigid, glassy state to a more flexible, rubbery state. A higher Tg value indicates that the PCB can withstand higher temperatures without deforming or losing its mechanical and electrical properties.

| Tg Range (°C) | PCB Material Classification |

|---|---|

| Below 130 | Low Tg |

| 130 – 170 | Medium Tg |

| Above 170 | High Tg |

RF4 PCBs typically have a Tg value above 170°C, making them suitable for high-temperature applications.

Advantages of RF4 PCBs

1. High Thermal Stability

The high Tg value of RF4 PCBs ensures excellent thermal stability, allowing them to maintain their mechanical and electrical properties even at elevated temperatures. This is particularly important for applications that generate significant heat, such as power electronics and high-performance computing.

2. Low Dielectric Constant and Loss Tangent

RF4 PCB materials have a low dielectric constant (Dk) and loss tangent (Df), which are essential for high-frequency applications. A low Dk value reduces the signal propagation delay, while a low Df value minimizes signal loss and attenuation. These properties enable RF4 PCBs to maintain signal integrity and minimize signal distortion, even at high frequencies.

3. Excellent Dimensional Stability

RF4 PCBs exhibit excellent dimensional stability, which means they resist warping and twisting under thermal stress. This is crucial for applications that require precise component placement and alignment, such as high-density interconnect (HDI) PCBs and fine-pitch ball grid array (BGA) packages.

4. Enhanced Reliability

The high Tg and excellent thermal stability of RF4 PCBs contribute to their enhanced reliability. These PCBs can withstand harsh environmental conditions, such as extreme temperatures, humidity, and vibrations, without compromising their performance or longevity. This makes RF4 PCBs ideal for mission-critical applications that demand the highest level of reliability.

RF4 PCB Manufacturing Process

The manufacturing process for RF4 PCBs involves several key steps to ensure the highest quality and performance:

1. Material Selection

Choosing the right RF4 PCB material is crucial for achieving the desired electrical and mechanical properties. Some common RF4 materials include:

- Rogers RO4000 series

- Isola IS400 series

- Nelco N4000-13 series

These materials offer a range of Tg values, dielectric constants, and loss tangents to suit various application requirements.

2. PCB Design and Layout

Proper PCB design and layout are essential for optimizing the performance of RF4 PCBs. Key considerations include:

- Controlled impedance routing

- Minimizing signal reflections and crosstalk

- Proper grounding and shielding

- Thermal management

Advanced PCB design software and simulation tools are used to ensure the design meets the required specifications and performance targets.

3. Fabrication

The fabrication process for RF4 PCBs involves multiple steps, including:

- Inner layer processing

- Lamination

- Drilling

- Plating

- Outer Layer processing

- Solder mask application

- Surface finish application

Strict process controls and quality assurance measures are implemented throughout the fabrication process to ensure the highest quality and consistency.

4. Testing and Inspection

Rigorous testing and inspection are performed to verify the electrical and mechanical properties of the RF4 PCBs. Some common tests include:

- Impedance testing

- Insertion loss testing

- Time-domain reflectometry (TDR)

- Microsectioning

- Thermal stress testing

These tests ensure that the RF4 PCBs meet the specified performance requirements and are free from defects.

Applications of RF4 PCBs

RF4 PCBs find applications in various industries and products, including:

1. Telecommunications

- 5G networks

- Satellite communications

- Wireless base stations

- Microwave radios

2. Aerospace and Defense

- Radar systems

- Avionics

- Missile guidance systems

- Satellite payloads

3. Automotive Electronics

- Advanced driver assistance systems (ADAS)

- Vehicle-to-vehicle (V2V) communication

- Autonomous driving systems

- In-vehicle infotainment systems

4. Medical Devices

- High-frequency imaging systems

- Wireless medical sensors

- Implantable devices

- Medical robotics

5. Industrial Automation

- Industrial control systems

- Robotics and motion control

- Wireless sensor networks

- Industrial IoT devices

Choosing the Right RF4 PCB Manufacturer

When selecting an RF4 PCB manufacturer, consider the following factors:

1. Experience and Expertise

Look for a manufacturer with extensive experience in producing high-performance RF4 PCBs. They should have a deep understanding of the materials, processes, and design considerations involved in manufacturing RF4 PCBs.

2. Quality Management System

Ensure that the manufacturer has a robust quality management system in place, such as ISO 9001 certification. This demonstrates their commitment to quality and continuous improvement.

3. Advanced Manufacturing Capabilities

Choose a manufacturer with state-of-the-art manufacturing equipment and capabilities, such as:

- High-precision drilling and routing machines

- Advanced lamination presses

- Automated optical inspection (AOI) systems

- Flying probe testers

These capabilities ensure the highest quality and consistency in RF4 PCB manufacturing.

4. Quick-Turn Prototyping

Look for a manufacturer that offers quick-turn prototyping services. This allows you to rapidly iterate on your designs and validate your concepts before committing to full-scale production.

5. Technical Support and Collaboration

Select a manufacturer that provides strong technical support and collaborates closely with you throughout the design and manufacturing process. They should have experienced application engineers who can provide guidance on material selection, design optimization, and manufacturability.

Frequently Asked Questions (FAQ)

1. What is the difference between RF4 and FR4 PCBs?

RF4 PCBs are made using high-performance materials with a higher Tg value and better electrical properties compared to standard FR4 PCBs. RF4 PCBs are suitable for high-frequency and high-speed applications, while FR4 PCBs are more common in general-purpose applications.

2. Can RF4 PCBs be used for multilayer designs?

Yes, RF4 PCBs can be manufactured in multilayer configurations, enabling complex designs with high layer counts and dense interconnects.

3. What are the typical lead times for RF4 PCB manufacturing?

Lead times for RF4 PCB manufacturing vary depending on the complexity of the design, the quantity ordered, and the manufacturer’s capacity. Typical lead times range from 2-4 weeks for prototypes and 4-8 weeks for production quantities.

4. How do I select the right RF4 PCB material for my application?

Selecting the right RF4 PCB material depends on several factors, including the operating frequency, dielectric constant, loss tangent, and thermal requirements of your application. Consult with your PCB manufacturer’s application engineers to determine the most suitable material for your specific needs.

5. Are RF4 PCBs more expensive than standard PCBs?

Yes, RF4 PCBs are generally more expensive than standard PCBs due to the specialized materials and manufacturing processes involved. However, the higher cost is justified by the superior performance and reliability of RF4 PCBs in demanding applications.

Conclusion

RF4 PCBs are the go-to choice for high-performance applications that demand excellent thermal stability, low dielectric constant and loss tangent, and enhanced reliability. By partnering with an experienced and capable RF4 PCB manufacturer, you can ensure that your designs are optimized for performance and manufacturability. With the right RF4 PCB Solution, you can push the boundaries of innovation and deliver cutting-edge products in various industries, from telecommunications and aerospace to automotive electronics and medical devices.

No responses yet