Overview of the Electronics Industry in India

The electronics industry is one of the fastest-growing sectors in India, with a compound annual growth rate (CAGR) of over 25% in the last decade. The industry encompasses various segments such as consumer electronics, industrial electronics, computer hardware, mobile phones, strategic electronics, and electronic components, including PCBs.

The Indian government has launched several initiatives to boost electronics manufacturing in the country, such as:

- Make in India: Aims to transform India into a global design and manufacturing hub

- National Policy on Electronics (NPE) 2019: Targets $400 billion turnover by 2025

- Production Linked Incentive (PLI) Scheme: Offers incentives for domestic manufacturing

- Electronic Manufacturing Clusters (EMC) Scheme: Provides infrastructure support

These policies have attracted significant investments from domestic and international companies, leading to the establishment of a robust electronics ecosystem in India.

PCB Manufacturing Scenario in India

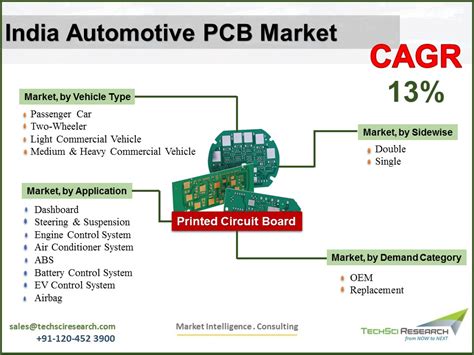

PCBs are the backbone of electronic devices, providing mechanical support and electrical connectivity to various components. The PCB manufacturing industry in India has witnessed significant growth in recent years, driven by the increasing demand for electronic products and the government’s supportive policies.

According to a report by the India Electronics and Semiconductor Association (IESA), the Indian PCB market is expected to grow at a CAGR of 20.8% from 2020 to 2025, reaching a value of $6.33 billion by 2025. The growth is attributed to the rising demand for PCBs in various sectors such as consumer electronics, automotive, aerospace & defense, and medical devices.

The Indian PCB manufacturing landscape consists of both domestic and international players. Some of the leading PCB manufacturers in India include:

- AT&S India Private Limited

- Epitome Components Pvt Ltd

- Shogini Technoarts Private Limited

- Ascent Circuits Pvt Ltd

- Genus Electrotech Ltd

- PCB Power Pvt Ltd

- Semikron Electronics Private Ltd

- Cirel Systems Pvt Ltd

- Fibro Technologies Pvt Ltd

- Fineline Circuits India Pvt Ltd

These manufacturers cater to a wide range of industries and offer various types of PCBs, such as single-sided, double-sided, multi-layer, flexible, and Rigid-Flex PCBs.

Advantages of PCB Manufacturing in India

India offers several advantages as a destination for PCB manufacturing, making it an attractive option for both domestic and international companies. Some of the key advantages include:

1. Cost Competitiveness

India’s lower labor costs and cost of raw materials compared to developed countries make it a cost-effective destination for PCB manufacturing. This cost advantage allows companies to produce PCBs at competitive prices without compromising on quality.

2. Skilled Workforce

India has a large pool of skilled engineers and technicians with expertise in electronics manufacturing. The country produces a significant number of engineering graduates every year, ensuring a steady supply of qualified professionals for the PCB industry.

3. Government Support

The Indian government’s supportive policies and incentives for electronics manufacturing have created a conducive environment for PCB production. Initiatives like Make in India, PLI Scheme, and EMC Scheme have attracted investments and encouraged the growth of the PCB sector.

4. Growing Domestic Market

India’s large and growing domestic market for electronic products creates a significant demand for PCBs. The increasing penetration of smartphones, consumer electronics, and the adoption of advanced technologies like 5G and IoT are driving the growth of the PCB market in India.

5. Strategic Location

India’s strategic location provides easy access to major global markets, including Southeast Asia, the Middle East, and Africa. This geographical advantage enables PCB manufacturers in India to serve customers in various regions efficiently.

Challenges and Opportunities

Despite the numerous advantages, the PCB manufacturing industry in India faces certain challenges that need to be addressed to realize its full potential. Some of the key challenges include:

-

Dependence on imported raw materials: India heavily relies on imports for key raw materials used in PCB manufacturing, such as Copper Clad laminates, pre-pregs, and specialty chemicals. This dependence leads to higher costs and supply chain vulnerabilities.

-

Limited advanced manufacturing capabilities: While India has a strong presence in the low-to-medium complexity PCB segment, it lags behind in advanced PCB technologies like HDI (High-Density Interconnect) and substrate-like PCBs. Investing in these advanced capabilities is crucial to meet the growing demand for high-end electronics.

-

Infrastructure and logistics challenges: India’s infrastructure and logistics network need further improvement to support the efficient movement of goods and materials. Addressing these challenges will enhance the competitiveness of the PCB industry.

Despite these challenges, the Indian PCB manufacturing industry presents significant opportunities for growth and investment. Some of the key opportunities include:

-

Domestic market potential: The growing demand for electronic products in India, driven by factors like rising disposable incomes, urbanization, and government initiatives like Digital India, creates a huge market for PCBs.

-

Export opportunities: India can leverage its cost advantage and manufacturing capabilities to serve the global PCB market. The ongoing trade tensions between the US and China have prompted many companies to diversify their supply chains, presenting an opportunity for India to attract investments.

-

Technological advancements: Adopting advanced technologies like HDI, flexible PCBs, and embedded components can help Indian PCB manufacturers move up the value chain and cater to high-end applications in sectors like aerospace, defense, and medical devices.

Future Outlook

The future of PCB manufacturing in India looks promising, driven by the growing demand for electronic products, supportive government policies, and the country’s competitive advantages. However, to fully realize this potential, the industry needs to address the challenges related to raw material dependence, advanced manufacturing capabilities, and infrastructure.

The Indian government’s continued support through initiatives like the PLI Scheme and the development of electronics manufacturing clusters will play a crucial role in attracting investments and fostering the growth of the PCB industry. Collaboration between industry stakeholders, academia, and the government is essential to bridge the skill gap, promote innovation, and create a robust ecosystem for PCB manufacturing in India.

As the global electronics industry looks for alternatives to China, India has the opportunity to position itself as a preferred destination for PCB manufacturing. By leveraging its strengths and addressing the challenges, India can emerge as a significant player in the global PCB market, contributing to the country’s economic growth and technological advancement.

FAQ

1. What is the current state of PCB manufacturing in India?

- The Indian PCB manufacturing industry has witnessed significant growth in recent years, driven by the increasing demand for electronic products and supportive government policies. The industry consists of both domestic and international players, catering to various sectors like consumer electronics, automotive, and aerospace & defense.

2. What are the advantages of manufacturing PCBs in India?

- India offers several advantages for PCB manufacturing, including:

- Cost competitiveness due to lower labor and raw material costs

- Availability of skilled workforce

- Government support through policies and incentives

- Growing domestic market for electronic products

- Strategic location for accessing global markets

3. What challenges does the Indian PCB manufacturing industry face?

- The key challenges faced by the Indian PCB industry include:

- Dependence on imported raw materials

- Limited advanced manufacturing capabilities in high-end PCB technologies

- Infrastructure and logistics challenges

4. What opportunities exist for the growth of PCB manufacturing in India?

- The opportunities for growth in the Indian PCB industry include:

- Huge domestic market potential driven by the increasing demand for electronic products

- Export opportunities, especially in the context of US-China trade tensions

- Adoption of advanced technologies to cater to high-end applications

5. What is the future outlook for PCB manufacturing in India?

- The future outlook for PCB manufacturing in India is positive, supported by the growing electronics industry, government initiatives, and the country’s competitive advantages. However, addressing challenges related to raw materials, advanced manufacturing, and infrastructure is crucial for realizing the industry’s full potential. With the right measures in place, India has the potential to emerge as a significant player in the global PCB market.

I hope this article provides a comprehensive overview of the PCB manufacturing landscape in India, highlighting the key aspects, challenges, opportunities, and future prospects. Let me know if you have any further questions or if there’s anything else you’d like me to include in the article.

No responses yet