Introduction to Carbon Nanotube PCBs

Carbon nanotubes (CNTs) have emerged as a groundbreaking material in the field of printed Circuit Board (PCB) technology. These nanoscale structures, composed of cylindrical carbon molecules, possess exceptional electrical, thermal, and mechanical properties that make them ideal for use in PCBs. The incorporation of carbon nanotubes in PCBs has the potential to revolutionize the electronics industry by enabling the development of smaller, faster, and more efficient electronic devices.

What are Carbon Nanotubes?

Carbon nanotubes are allotropes of carbon with a cylindrical nanostructure. They are essentially rolled-up sheets of graphene, a single layer of carbon atoms arranged in a hexagonal lattice. CNTs can be classified into two main categories: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). SWCNTs consist of a single graphene sheet rolled into a cylinder, while MWCNTs are composed of multiple concentric graphene tubes.

Properties of Carbon Nanotubes

Carbon nanotubes exhibit several remarkable properties that make them suitable for use in PCBs:

- High Electrical Conductivity: CNTs have excellent electrical conductivity, allowing for efficient current flow and reduced resistance in PCB Traces.

- High Thermal Conductivity: The thermal conductivity of CNTs is significantly higher than that of traditional PCB Materials, enabling better heat dissipation and thermal management.

- Mechanical Strength: CNTs possess exceptional mechanical strength, with a tensile strength up to 100 times greater than that of steel. This strength contributes to the durability and reliability of CNT-based PCBs.

- Lightweight and Flexible: CNTs are lightweight and can be incorporated into flexible substrates, enabling the development of flexible and bendable PCBs.

Advantages of Carbon Nanotube PCBs

Miniaturization and High-Density Packaging

One of the primary advantages of using carbon nanotubes in PCBs is the ability to achieve miniaturization and high-density packaging. The nanoscale dimensions of CNTs allow for the fabrication of ultra-fine traces and interconnects, enabling the creation of smaller and more compact PCBs. This miniaturization is crucial for the development of advanced electronic devices, such as smartphones, wearables, and Internet of Things (IoT) devices, where space is limited.

Improved Signal Integrity and Reduced Crosstalk

Carbon nanotube PCBs offer improved signal integrity and reduced crosstalk compared to traditional PCBs. The high electrical conductivity and low resistance of CNTs result in faster signal propagation and reduced signal losses. Additionally, the nanoscale dimensions of CNTs minimize the capacitive and inductive coupling between adjacent traces, reducing crosstalk and ensuring cleaner and more reliable signal transmission.

Enhanced Thermal Management

Effective thermal management is essential for the performance and reliability of electronic devices. Carbon nanotube PCBs excel in this aspect due to their high thermal conductivity. CNTs can efficiently dissipate heat away from critical components, preventing thermal hotspots and reducing the risk of thermal-induced failures. This enhanced thermal management capability allows for higher power densities and improved overall system performance.

Flexibility and Bendability

Carbon nanotubes can be incorporated into flexible substrates, such as polymers or thin films, to create flexible and bendable PCBs. This flexibility opens up new possibilities for the design and integration of electronics into non-traditional form factors. Flexible CNT-based PCBs can be used in applications such as wearable electronics, flexible displays, and medical devices, where conformity to curved surfaces or human body contours is required.

Fabrication Techniques for Carbon Nanotube PCBs

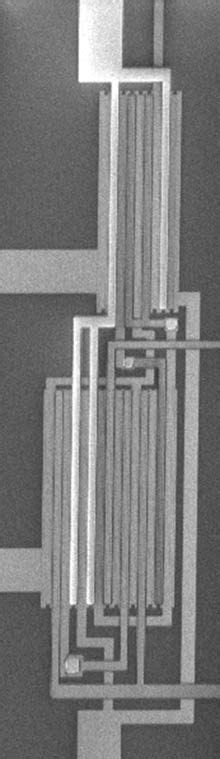

Chemical Vapor Deposition (CVD)

Chemical vapor deposition (CVD) is a widely used technique for the synthesis of carbon nanotubes. In the CVD process, a carbon-containing precursor gas, such as methane or ethylene, is introduced into a reaction chamber along with a catalyst, typically a transition metal nanoparticle. The precursor gas decomposes at high temperatures, and the carbon atoms self-assemble into nanotubes on the catalyst surface. CVD allows for the controlled growth of CNTs with desired properties and orientations.

Inkjet Printing

Inkjet printing is a promising technique for the fabrication of carbon nanotube PCBs. In this method, a CNT-based ink is formulated by dispersing CNTs in a suitable solvent along with additives such as surfactants and binders. The ink is then deposited onto a substrate using an inkjet printer, forming the desired PCB traces and patterns. Inkjet printing offers advantages such as high resolution, precise material deposition, and the ability to create complex geometries.

Screen Printing

Screen printing is another technique used for the fabrication of carbon nanotube PCBs. In screen printing, a mesh screen with the desired PCB pattern is used as a stencil. A CNT-based paste is spread over the screen and forced through the openings onto the substrate, forming the PCB traces. Screen printing is suitable for large-scale production and can be used to create thick and robust CNT layers.

Challenges and Future Prospects

Dispersion and Alignment of Carbon Nanotubes

One of the challenges in the fabrication of carbon nanotube PCBs is achieving uniform dispersion and alignment of the nanotubes. CNTs have a tendency to agglomerate due to strong van der Waals forces, which can lead to non-uniform electrical and thermal properties. Effective dispersion techniques, such as ultrasonication and the use of surfactants, are crucial for obtaining well-dispersed CNT suspensions. Additionally, techniques like electric or magnetic field alignment can be employed to control the orientation of CNTs, ensuring optimal performance.

Scalability and Cost-Effectiveness

The scalability and cost-effectiveness of carbon nanotube PCB manufacturing are important considerations for widespread adoption. While CNTs offer superior properties, their production and integration into PCBs can be more expensive compared to traditional materials. Efforts are being made to develop cost-effective synthesis methods and large-scale production techniques to make CNT-based PCBs more economically viable.

Integration with Existing PCB Manufacturing Processes

Integrating carbon nanotube materials into existing PCB manufacturing processes poses challenges. Compatibility with current equipment, materials, and process flows needs to be addressed. Adaptations and optimizations may be required to ensure seamless integration of CNTs into PCB fabrication lines. Collaboration between material scientists, process engineers, and PCB manufacturers is essential to overcome these challenges and enable the successful adoption of CNT technology in the PCB industry.

Frequently Asked Questions (FAQ)

-

Q: What are the key benefits of using carbon nanotubes in PCBs?

A: Carbon nanotubes offer several benefits when used in PCBs, including improved electrical conductivity, enhanced thermal management, increased mechanical strength, and the ability to achieve miniaturization and high-density packaging. -

Q: How do carbon nanotube PCBs compare to traditional PCBs in terms of signal integrity?

A: Carbon nanotube PCBs offer improved signal integrity compared to traditional PCBs. The high electrical conductivity and low resistance of CNTs result in faster signal propagation and reduced signal losses. Additionally, the nanoscale dimensions of CNTs minimize crosstalk between adjacent traces, ensuring cleaner and more reliable signal transmission. -

Q: Can carbon nanotube PCBs be made flexible?

A: Yes, carbon nanotubes can be incorporated into flexible substrates, such as polymers or thin films, to create flexible and bendable PCBs. This flexibility enables the development of electronics for applications that require conformity to curved surfaces or human body contours, such as wearable devices and medical implants. -

Q: What are the main fabrication techniques used for carbon nanotube PCBs?

A: The main fabrication techniques for carbon nanotube PCBs include chemical vapor deposition (CVD), inkjet printing, and screen printing. CVD is used for the synthesis of CNTs, while inkjet printing and screen printing are used for the deposition of CNT-based inks or pastes onto substrates to form the desired PCB patterns. -

Q: Are there any challenges in the widespread adoption of carbon nanotube PCBs?

A: Yes, there are challenges that need to be addressed for the widespread adoption of carbon nanotube PCBs. These include achieving uniform dispersion and alignment of CNTs, ensuring scalability and cost-effectiveness of manufacturing processes, and integrating CNT materials into existing PCB fabrication lines. Continued research and development efforts are necessary to overcome these challenges and enable the successful commercialization of CNT-based PCBs.

Conclusion

Carbon nanotube materials have emerged as a promising solution for the next generation of printed circuit boards. The exceptional electrical, thermal, and mechanical properties of CNTs make them ideal for use in PCBs, offering advantages such as miniaturization, improved signal integrity, enhanced thermal management, and flexibility. The incorporation of CNTs in PCBs has the potential to revolutionize the electronics industry, enabling the development of smaller, faster, and more efficient electronic devices.

However, challenges such as achieving uniform dispersion and alignment of CNTs, ensuring scalability and cost-effectiveness, and integrating CNT materials into existing PCB manufacturing processes need to be addressed. Continued research and development efforts, along with collaboration between material scientists, process engineers, and PCB manufacturers, are essential to overcome these challenges and realize the full potential of carbon nanotube PCBs.

As the demand for high-performance and compact electronic devices continues to grow, the adoption of carbon nanotube materials in PCBs is expected to increase. With advancements in synthesis techniques, fabrication processes, and material integration, CNT-based PCBs have the potential to become the standard in the electronics industry, driving innovation and enabling the development of next-generation electronic devices.

No responses yet