What is a PCB?

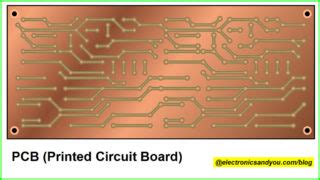

A PCB, or Printed Circuit Board, is the foundation of most electronic devices. It is a flat board made of insulating materials, such as fiberglass or composite epoxy, with conductive pathways etched or printed onto its surface. These pathways, known as traces, connect various electronic components and allow for the flow of electrical signals.

Key Features of a PCB

-

Substrate Material: PCBs are typically made from a non-conductive substrate, such as FR-4 (a glass-reinforced epoxy laminate), which provides a stable base for the conductive traces and components.

-

Copper Traces: Thin layers of copper are laminated onto the substrate, forming the conductive pathways that connect components. These traces are usually etched or printed onto the board using a photolithographic process.

-

Solder Mask: A protective layer, known as the solder mask, is applied over the copper traces to prevent accidental short circuits and improve the board’s durability. The solder mask is typically green, but other colors are available.

-

Silkscreen: A silkscreen layer is added to the PCB to provide text, logos, and component identifiers. This helps with assembly and troubleshooting.

-

Mounting Holes and Vias: PCBs often include mounting holes for attaching the board to an enclosure or chassis. Vias, which are small holes drilled through the board, allow for connections between different layers of a multi-layer PCB.

Types of PCBs

PCBs come in various types, each with its own characteristics and applications:

| PCB Type | Layers | Application |

|---|---|---|

| Single-sided | 1 | Simple, low-cost devices |

| Double-sided | 2 | Moderately complex devices |

| Multi-layer | 3+ | Complex, high-performance devices |

| Flexible | Varies | Wearables, compact devices |

| Rigid-Flex | Varies | Devices requiring both rigid and flexible sections |

What is a PCBA?

A PCBA, or Printed Circuit Board Assembly, is a PCB that has been populated with electronic components. It is the result of the assembly process, where components are soldered onto the board, transforming it from a bare PCB into a functional circuit.

The PCBA Assembly Process

The PCBA assembly process typically involves the following steps:

-

Solder Paste Application: Solder paste, a mixture of tiny solder particles and flux, is precisely applied to the PCB’s pads using a stencil or screen printing process.

-

Component Placement: Surface mount components are placed onto the solder paste using pick-and-place machines. These machines use computer-controlled nozzles to accurately position components based on the PCB design files.

-

Reflow Soldering: The populated PCB is passed through a reflow oven, which heats the board to a specific temperature profile. This melts the solder paste, forming a permanent connection between the components and the PCB.

-

Through-Hole Component Placement: If the PCBA includes through-hole components, they are inserted manually or by machines into the designated holes on the PCB.

-

Wave Soldering: For through-hole components, the PCBA is passed over a wave of molten solder. The solder adheres to the component leads and the PCB’s plated holes, creating a strong electrical and mechanical connection.

-

Inspection and Testing: The assembLED PCBA undergoes various inspections and tests to ensure proper functionality and quality. This may include automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT).

Types of Components Used in PCBA

PCBAs can incorporate a wide variety of electronic components, depending on the device’s function and design. Some common component types include:

- Resistors

- Capacitors

- Inductors

- Diodes

- Transistors

- Integrated Circuits (ICs)

- Connectors

- Switches

- LEDs

Key Differences Between PCB and PCBA

Now that we’ve explored the basics of PCB and PCBA, let’s summarize the main differences between the two:

| Aspect | PCB | PCBA |

|---|---|---|

| Definition | A Bare Board with conductive traces | A PCB populated with electronic components |

| Components | No components, only copper traces and pads | Includes various electronic components soldered onto the board |

| Functionality | Provides a foundation for the circuit but does not function on its own | A complete, functional circuit ready for integration into a device |

| Manufacturing Process | Involves substrate preparation, copper lamination, etching, and finishing | Includes PCB fabrication, component placement, soldering, and testing |

| Cost | Lower cost compared to PCBA | Higher cost due to the addition of components and assembly processes |

| Time to Market | Faster production time | Longer production time due to the added assembly steps |

Applications of PCB and PCBA

PCBs and PCBAs find applications across a wide range of industries and products. Some common examples include:

- Consumer Electronics: Smartphones, laptops, tablets, televisions, and home appliances

- Automotive: Engine control units, infotainment systems, sensors, and power management

- Medical Devices: Diagnostic equipment, monitoring systems, and implantable devices

- Industrial Equipment: Control systems, automation, and data acquisition

- Aerospace and Defense: Avionics, communication systems, and military electronics

- IoT Devices: Smart home devices, wearables, and sensor networks

Choosing Between PCB and PCBA

When deciding between using a PCB or a PCBA for your project, consider the following factors:

-

Project Requirements: Determine whether your project needs a bare PCB for further assembly or a fully assembled PCBA.

-

In-House Capabilities: Assess your organization’s ability to handle PCB Assembly. If you lack the necessary equipment and expertise, opting for a PCBA may be more practical.

-

Time to Market: If you need to bring your product to market quickly, a PCBA may be the better choice, as it eliminates the need for in-house assembly.

-

Cost: Consider the total cost of ownership, including the cost of the PCB, components, assembly, and testing. In some cases, outsourcing PCBA production may be more cost-effective.

-

Customization: If your project requires a high degree of customization or frequent design changes, working with a bare PCB may provide more flexibility.

Frequently Asked Questions (FAQ)

-

Q: Can a PCB function without components?

A: No, a PCB alone cannot function as an electronic circuit. It requires the addition of components through the assembly process to become a functional PCBA. -

Q: What is the difference between surface mount and through-hole components?

A: Surface mount components are placed directly onto the surface of the PCB, while through-hole components have leads that are inserted into holes drilled in the PCB. Surface mount technology allows for smaller components and higher component density, while through-hole components offer stronger mechanical connections. -

Q: How do I choose the right substrate material for my PCB?

A: The choice of substrate material depends on factors such as the operating environment, required performance, and cost. FR-4 is a common choice for most applications, but other materials like polyimide or ceramic may be used for high-temperature or high-frequency applications. -

Q: What is the purpose of the solder mask on a PCB?

A: The solder mask is a protective layer that covers the copper traces on a PCB. It prevents accidental short circuits, provides electrical insulation, and protects the traces from environmental damage. -

Q: How can I ensure the quality of my PCBA?

A: To ensure PCBA quality, follow best practices in design, component selection, and manufacturing. This includes adhering to design guidelines, using reputable component suppliers, and implementing strict quality control measures during the assembly process. Additionally, thorough testing and inspection can help identify and address any issues before the PCBA is integrated into the final product.

Conclusion

Understanding the difference between PCB and PCBA is crucial for anyone involved in electronics manufacturing. While a PCB serves as the foundation for an electronic circuit, it is the PCBA that brings the circuit to life by incorporating the necessary components. By considering factors such as project requirements, in-house capabilities, time to market, cost, and customization, you can make an informed decision on whether to use a PCB or PCBA for your specific application.

As technology continues to advance, the complexity and performance of PCBs and PCBAs will only continue to grow. Staying up-to-date with the latest trends, materials, and manufacturing processes will be key to developing innovative and reliable electronic products in the future.

No responses yet