Introduction to LED PCBs

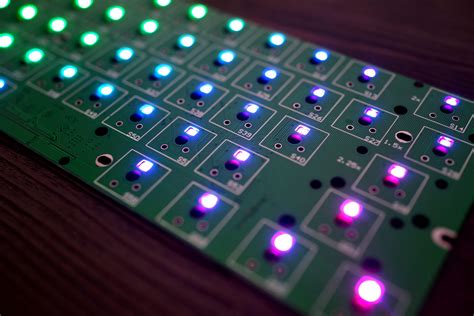

LED PCB stands for Light Emitting Diode Printed Circuit Board. It is a specialized type of printed circuit board designed specifically to power and control LEDs (light emitting diodes). LED PCBs provide mechanical support and electrical connections for surface mounted and through-hole LEDs.

LEDs have become increasingly popular in recent years for a wide range of lighting applications due to their energy efficiency, long lifespan, durability, and compact size compared to traditional incandescent bulbs. LEDs require a constant current power supply and proper heat dissipation, which is where LED PCBs come into play. The PCB is designed to deliver the optimal current to each LED and to effectively draw heat away from the LEDs to the PCB where it can be dissipated.

Advantages of LED PCBs

LED PCBs offer several key advantages:

-

Efficient power delivery – The copper traces on the PCB are designed to provide a constant current to each LED for maximum brightness and longevity.

-

Heat dissipation – LEDs generate a significant amount of heat. LED PCBs use thermal vias and heatsinks to draw heat away from the LEDs to prevent damage.

-

Compact designs – LEDs and their supporting circuitry can be tightly packed onto a PCB, enabling very compact, high-density lighting solutions.

-

Customizable – LED PCBs can be designed in any shape and size with custom LED layouts to suit the specific application.

-

Durable – PCBs are very rugged and resistant to shock and vibration compared to other lighting solutions with wired connections.

LED PCB Design Considerations

Designing an LED PCB requires careful consideration of the electrical, thermal and mechanical requirements. Here are some of the key design factors:

LED Type and Quantity

The first step is determining what type of LEDs will be used (surface mount or through-hole) and how many. This dictates the size of the PCB and the layout. For high-density designs, surface mount LEDs are preferred.

Current and Voltage

LEDs are current-driven devices that require a precise amount of current to operate optimally and avoid damage. The PCB must be designed to deliver the right current to each LED. This involves selecting the appropriate resistors and designing the copper traces to handle the required current.

Thermal Management

LEDs generate a significant amount of heat which must be dissipated to prevent damage and color shifting. LED PCBs use several techniques to remove heat:

-

Thermal vias – These are small holes that allow heat to pass from the component layer to the bottom of the board more efficiently.

-

Thick copper layers – Using thicker copper on the component layer helps spread heat across the PCB for better dissipation.

-

Metal Core PCBs – For high-power LEDs, aluminum or copper core PCBs provide even better heat sinking.

-

Heatsinks and cooling fins – Externally attached heatsinks with cooling fins can further aid in heat dissipation for very high-power LED arrays.

Control Circuitry

LED PCBs often incorporate resistors, drivers, and microcontrollers to precisely control the current delivered to each LED. For color-changing RGB LEDs, the PCB will include an LED driver chip that enables each color to be individually adjusted to produce any color output. More advanced LED PCBs may include wireless control chips, sensors, and other components for smart lighting applications.

LED PCB Manufacturing Process

LED PCBs are manufactured using the same processes as standard PCBs but with extra steps and features for LED mounting and thermal management. The process involves:

-

PCB Design – The PCB layout is designed using CAD software, carefully placing the LEDs, resistors, traces and any other components.

-

Printing – The design is printed onto the copper clad board using a photoresist and then etched with chemicals to remove the unmasked copper, leaving only the desired traces.

-

Drilling – Holes are drilled for through-hole components and vias.

-

Soldermask and Silkscreen – A green soldermask coating is applied to protect the copper traces, and a white silkscreen layer is added to label components and connectors.

-

Surface Finish – The exposed copper contacts are coated to prevent oxidation, typically with HASL (hot air solder leveling), lead-free HASL, or immersion gold/silver.

-

Component Mounting – The LEDs and other components are mounted onto the board, either by hand for small runs or by automated pick-and-place machines for larger volumes.

-

Reflow Soldering – The board is run through an oven to melt the solder paste and permanently attach the components.

-

Quality Control – The finished LED PCB is thoroughly tested to ensure all LEDs are functioning properly and the board meets specifications before being installed in the final lighting fixture.

Types of LED PCBs

LED PCBs come in a wide variety of configurations to suit different applications. Some common types include:

Rigid LED PCBs

These are the most common type of LED PCB. They are made from a solid substrate material, typically FR-4 fiberglass. Rigid PCBs offer good durability and thermal stability. They can be single-layer for simple designs or multi-layer for more complex circuits.

Flexible LED PCBs

Flexible PCBs are made from thin, flexible plastic substrates like polyimide or PEEK. They can bend and flex to conform to curved surfaces or move with an articulating light fixture. Flex PCBs are commonly used in automotive lighting, signs, and wearable electronics.

Metal Core LED PCBs

Metal core PCBs (MCPCBs) use an aluminum or copper base layer for superior heat dissipation compared to FR-4. The LED Circuit layer is bonded to the metal core with a thermally conductive dielectric layer. MCPCBs are used for high-power LED applications like automotive headlights, streetlights, and industrial lighting.

High Density Interconnect (HDI) LED PCBs

HDI PCBs use microvias and very fine traces to achieve extremely high component density. This enables a large number of LEDs to be packed onto a small PCB for compact, high-brightness lighting applications. HDI is commonly used in camera flash modules, medical devices, and miniature displays.

Applications of LED PCBs

LED PCBs are used in a huge range of lighting applications across many industries. Some examples include:

| Industry | Applications |

|---|---|

| Automotive | Headlights, taillights, interior lighting, instrument panels |

| General Lighting | Light bulbs, fixtures, lamps |

| Signage | Channel letters, lightboxes, digital billboards |

| Aerospace | Aircraft and spacecraft interior/exterior lighting |

| Medical | Medical devices, surgical lighting, dental lighting |

| Consumer Electronics | TVs, monitors, smartphones, gaming PCs, keypads |

The small size, durability, and low power consumption of LED PCBs make them ideal for portable battery-powered devices. Their brightness and color range make them perfect for decorative lighting and dynamic “mood” lighting that can be changed with the push of a button.

Future of LED PCBs

LED PCB technology continues to evolve at a rapid pace, driven by advances in LED efficiency and the push toward smart, connected lighting. Some key trends shaping the future of LED PCBs include:

Smart Lighting

LED PCBs are increasingly incorporating sensors, wireless chips, and microcontrollers to enable smart lighting features like occupancy sensing, daylight harvesting, and remote control via smartphones and smart home assistants. This allows for greener, more automated lighting that responds to the environment.

Color Tuning

Newer LED PCBs include multiple color LEDs (red, green, blue, amber, etc.) that can be independently adjusted to produce a wide gamut of colors and color temperatures. This enables lighting that can be tuned to the time of day or the desired ambiance at the push of a button.

Flexible and Wearable Lighting

Advances in flexible circuit materials are enabling LED PCBs to be integrated into clothing, furniture, and other soft goods for decorative and safety lighting applications. Flexible LED strips are also being used for contour accent lighting on vehicles and buildings.

Sustainable Manufacturing

As with all electronics, there is a growing emphasis on sustainable, eco-friendly manufacturing processes for LED PCBs. This includes the use of lead-free solders, recyclable substrates, and low-impact coatings. Many LED PCB manufacturers are also implementing waste reduction and energy efficiency measures in their facilities.

Frequently Asked Questions (FAQ)

1. What is the difference between an LED PCB and a regular PCB?

An LED PCB is a specialized type of PCB designed specifically to power and control LEDs. It includes features like constant current traces, thermal management, and LED drivers that are not found on regular PCBs. Regular PCBs are more general purpose and can be used for a wide variety of electronic circuits.

2. Can I use a regular PCB for LEDs?

You can use a regular PCB for a simple LED circuit, but it will not be optimized for LED performance and longevity. Regular PCBs lack the thermal management and constant current features of dedicated LED PCBs. For best results, it’s recommended to use a PCB specifically designed for LEDs.

3. What are the benefits of using LED PCBs?

LED PCBs offer several benefits compared to other LED mounting methods:

- Efficient heat dissipation for longer LED life

- Constant current for optimal brightness and color

- Compact, high-density designs

- Durable construction resistant to shock and vibration

- Easy integration of control circuitry and sensors

4. How long do LED PCBs last?

The lifespan of an LED PCB depends on many factors including the quality of the LEDs, the operating temperature, and the drive current. In general, a well-designed LED PCB can last 50,000 hours or more before the LEDs begin to significantly degrade. This is much longer than incandescent bulbs which typically last around 1,000 hours.

5. Are LED PCBs environmentally friendly?

LED PCBs are generally considered more environmentally friendly than traditional lighting solutions due to their low power consumption, long lifespan, and lack of toxic mercury. However, PCBs do contain some hazardous materials like lead and brominated flame retardants which can pose environmental risks if not properly disposed of. Many LED PCB manufacturers are moving towards more sustainable, eco-friendly materials and processes.

Conclusion

LED PCBs are a critical component in modern lighting solutions, providing efficient, reliable, and compact illumination for a wide range of applications. By optimizing power delivery and thermal management, LED PCBs enable LEDs to operate at peak performance for longer lifespans than traditional lighting solutions.

As LED technology continues to improve and smart, connected lighting becomes the norm, LED PCBs will play an increasingly important role. Advances in materials, manufacturing processes, and integrated control circuitry are enabling even more compact, flexible, and intelligent LED lighting solutions.

Whether illuminating the dashboard of a car, the screen of a smartphone, or the streets of a smart city, LED PCBs are poised to light the way into a brighter, more efficient future.

No responses yet