What is a Rigid PCB?

A rigid PCB, also known as a standard PCB, is a type of printed circuit board that is made from a solid, non-flexible material. It is typically composed of multiple layers of copper and insulating material, such as fiberglass or epoxy resin. The copper layers are etched with the desired circuit pattern, and the insulating material provides support and prevents short circuits between the layers.

Characteristics of Rigid PCBs

-

Durability: Rigid PCBs are known for their durability and ability to withstand harsh environmental conditions. They can operate in a wide range of temperatures and are resistant to vibrations and impacts.

-

Multilayer Capabilities: Rigid PCBs can be manufactured with multiple layers, allowing for more complex circuit designs and higher component density. This is particularly useful for applications that require a large number of components or have space constraints.

-

Cost-effective: For high-volume production, rigid PCBs are generally more cost-effective compared to flex PCBs. The manufacturing process is well-established, and the materials used are readily available.

Applications of Rigid PCBs

Rigid PCBs are widely used in various industries and applications, including:

- Consumer electronics (e.g., smartphones, laptops, televisions)

- Automotive electronics (e.g., engine control units, infotainment systems)

- Industrial equipment (e.g., sensors, control systems)

- Medical devices (e.g., diagnostic equipment, monitoring systems)

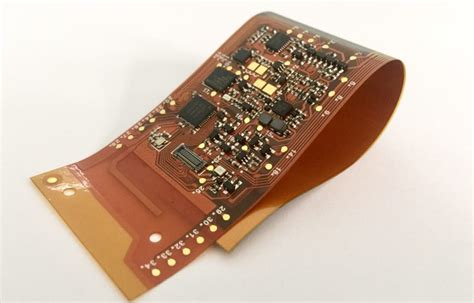

What is a Flex PCB?

A flex PCB, short for flexible printed circuit board, is a type of PCB that is made from a thin, flexible material. It consists of a conductive layer, typically copper, that is printed on a flexible substrate, such as polyimide or polyester. Flex PCBs can be bent, twisted, and folded without damaging the circuit or components.

Characteristics of Flex PCBs

-

Flexibility: The most significant advantage of flex PCBs is their ability to bend and conform to various shapes. This allows for more design freedom and enables the integration of electronics into tight spaces or movable parts.

-

Lightweight: Flex PCBs are generally lighter than rigid PCBs due to the use of thinner materials. This makes them ideal for applications where weight is a critical factor, such as in aerospace or wearable devices.

-

Durability: Despite their flexibility, flex PCBs are still durable and can withstand repeated bending and flexing. They are also resistant to vibrations and impacts, making them suitable for applications that experience frequent movement or stress.

Applications of Flex PCBs

Flex PCBs are used in various industries and applications where flexibility, lightweight, and space constraints are important factors. Some common applications include:

- Wearable electronics (e.g., smartwatches, fitness trackers)

- Medical devices (e.g., implantable devices, hearing aids)

- Aerospace and defense (e.g., satellites, aircraft, military equipment)

- Automotive electronics (e.g., dashboard displays, sensors)

- Consumer electronics (e.g., camera modules, display connectors)

Rigid-Flex PCBs: The Best of Both Worlds

Rigid-flex PCBs are a hybrid solution that combines the benefits of both rigid and flex PCBs. They consist of rigid PCB sections connected by Flexible PCB sections, allowing for a mix of stability and flexibility within a single board.

Advantages of Rigid-Flex PCBs

-

Space Savings: Rigid-flex PCBs can significantly reduce the overall size and weight of electronic assemblies by eliminating the need for separate rigid and flex PCBs and the associated connectors.

-

Improved Reliability: By reducing the number of interconnects and connectors, rigid-flex PCBs minimize the potential points of failure, resulting in improved reliability and durability.

-

Design Flexibility: Rigid-flex PCBs offer greater design flexibility by allowing the placement of components on both rigid and flexible sections. This enables more efficient use of space and the ability to create unique form factors.

Applications of Rigid-Flex PCBs

Rigid-flex PCBs are used in various industries and applications where the benefits of both rigid and flex PCBs are required. Some common applications include:

- Aerospace and defense (e.g., avionics, missile systems)

- Medical devices (e.g., surgical instruments, wearable health monitors)

- Automotive electronics (e.g., advanced driver assistance systems, electric vehicle batteries)

- Industrial equipment (e.g., robotics, automation systems)

Comparison Table: Rigid PCB vs. Flex PCB

| Feature | Rigid PCB | Flex PCB |

|---|---|---|

| Material | Solid, non-flexible (e.g., fiberglass, epoxy resin) | Thin, flexible (e.g., polyimide, polyester) |

| Flexibility | No flexibility, maintains a fixed shape | Can bend, twist, and fold without damaging the circuit |

| Durability | High durability, resistant to harsh environments | Durable and resistant to vibrations and impacts |

| Weight | Heavier compared to flex PCBs | Lightweight due to thinner materials |

| Multilayer Capabilities | Can have multiple layers for complex designs | Limited multilayer capabilities compared to rigid PCBs |

| Cost | Cost-effective for high-volume production | Generally more expensive than rigid PCBs |

| Common Applications | Consumer electronics, automotive, industrial, medical | Wearables, medical devices, aerospace, automotive |

FAQs

-

Q: Can flex PCBs be used in high-temperature environments?

A: Flex PCBs can operate in a wide range of temperatures, depending on the materials used. Polyimide, a common substrate material for flex PCBs, has a high heat resistance and can withstand temperatures up to 260°C. -

Q: Are rigid PCBs more reliable than flex PCBs?

A: Both rigid and flex PCBs can be highly reliable when designed and manufactured properly. Rigid PCBs are known for their durability in harsh environments, while flex PCBs are resistant to vibrations and impacts. The reliability of a PCB depends on various factors, such as the quality of materials, manufacturing processes, and the specific application requirements. -

Q: Can rigid-flex PCBs be repaired?

A: Repairing rigid-flex PCBs can be more challenging compared to rigid PCBs due to the complex structure and the presence of both rigid and flexible sections. However, skilled technicians with the proper tools and techniques can perform repairs on rigid-flex PCBs, depending on the extent of the damage and the accessibility of the affected area. -

Q: Are flex PCBs more expensive than rigid PCBs?

A: In general, flex PCBs are more expensive than rigid PCBs due to the specialized materials and manufacturing processes involved. However, the cost difference can be justified in applications where the benefits of flexibility, lightweight, and space savings are crucial. -

Q: Can rigid PCBs be replaced by flex PCBs in all applications?

A: No, rigid PCBs cannot be replaced by flex PCBs in all applications. While flex PCBs offer unique advantages in terms of flexibility and space savings, rigid PCBs are still the preferred choice for many applications due to their durability, cost-effectiveness, and multilayer capabilities. The choice between rigid and flex PCBs depends on the specific requirements of the application, such as the operating environment, space constraints, and performance needs.

In conclusion, rigid PCBs and flex PCBs are two distinct types of printed circuit boards that cater to different application requirements. Rigid PCBs offer durability, multilayer capabilities, and cost-effectiveness, making them suitable for a wide range of applications in consumer electronics, automotive, industrial, and medical industries. On the other hand, flex PCBs provide flexibility, lightweight, and space savings, making them ideal for wearables, medical devices, aerospace, and automotive applications where these attributes are crucial.

Rigid-flex PCBs, a hybrid solution combining the benefits of both rigid and flex PCBs, offer the best of both worlds by providing a mix of stability and flexibility within a single board. They enable space savings, improved reliability, and greater design flexibility, making them suitable for applications in aerospace, medical devices, automotive electronics, and industrial equipment.

When selecting between rigid PCBs, flex PCBs, or rigid-flex PCBs, it is essential to consider the specific requirements of the application, such as the operating environment, space constraints, performance needs, and cost. By understanding the differences and advantages of each type of PCB, designers and engineers can make informed decisions and create electronic assemblies that meet the unique demands of their applications.

No responses yet