Table of Contents

- Introduction to ExpressPCB

- Setting Up ExpressPCB

- Creating a New PCB Project

- Designing the Schematic

- Adding Components

- Connecting Components

- Labeling and Annotating

- PCB Layout

- Creating a New PCB Layout

- Placing Components

- Routing Traces

- Adding Copper Pours

- Design Rule Check

- Generating Manufacturing Files

- Ordering PCBs

- Troubleshooting Common Issues

- Advanced Features and Techniques

- Frequently Asked Questions (FAQ)

- Conclusion

Introduction to ExpressPCB

ExpressPCB is a comprehensive software package that allows users to design and manufacture PCBs with ease. It offers a simple and intuitive interface, making it suitable for both beginners and experienced designers. With ExpressPCB, you can create schematics, design PCB layouts, and generate the necessary files for manufacturing.

Setting Up ExpressPCB

To get started with ExpressPCB, you need to download and install the software on your computer. Visit the official ExpressPCB website (https://www.expresspcb.com/) and download the latest version of the software. Follow the installation instructions provided by the installer.

Once the installation is complete, launch ExpressPCB and familiarize yourself with the user interface. The main window consists of several panels, including the schematic editor, PCB layout editor, and component libraries.

Creating a New PCB Project

To create a new PCB project in ExpressPCB, follow these steps:

- Click on “File” in the menu bar and select “New.”

- Choose “PCB Project” from the available options.

- Enter a name for your project and select the desired location to save it.

- Click “OK” to create the new project.

ExpressPCB will create a new project folder containing the necessary files for your PCB design.

Designing the Schematic

The first step in creating a PCB is designing the schematic. The schematic represents the electrical connections between components in your circuit. ExpressPCB provides a user-friendly schematic editor to help you create your circuit diagram.

Adding Components

To add components to your schematic:

- Open the component library by clicking on “Library” in the menu bar and selecting “Component Library.”

- Browse through the available components or use the search function to find the desired component.

- Drag and drop the component onto the schematic canvas.

- Repeat the process for all the components in your circuit.

Connecting Components

To establish electrical connections between components:

- Click on the “Wire” tool in the toolbar.

- Click on the first component’s pin you want to connect.

- Click on the second component’s pin to complete the connection.

- Repeat the process for all the necessary connections in your circuit.

Labeling and Annotating

To improve the readability and clarity of your schematic:

- Use the “Text” tool to add labels and annotations.

- Assign unique reference designators to each component.

- Add net names to important connections.

- Provide clear and concise descriptions for each section of your circuit.

PCB Layout

Once you have completed the schematic design, it’s time to create the PCB layout. The PCB layout determines the physical placement of components and the routing of traces on the PCB.

Creating a New PCB Layout

To create a new PCB layout:

- Click on “File” in the menu bar and select “New.”

- Choose “PCB Layout” from the available options.

- Select the desired PCB size and layer configuration.

- Click “OK” to create the new PCB layout.

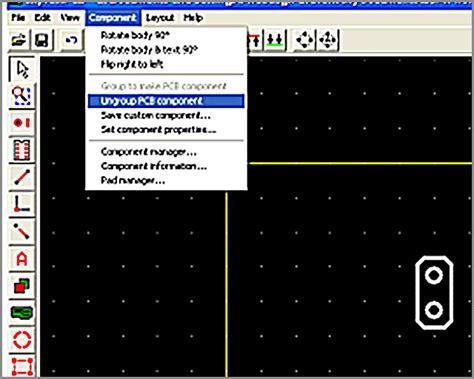

Placing Components

To place components on the PCB layout:

- Open the component placement window by clicking on “Tools” in the menu bar and selecting “Component Placement.”

- Select the components from the list and place them on the PCB layout canvas.

- Arrange the components in a logical and space-efficient manner.

- Ensure proper spacing between components to avoid interference and manufacturing issues.

Routing Traces

To route traces between components:

- Click on the “Route” tool in the toolbar.

- Select the appropriate trace width based on the current requirements.

- Click on the starting pad of a connection and route the trace to the ending pad.

- Use vias to transition between layers when necessary.

- Ensure that traces do not violate any design rules, such as minimum trace width and spacing.

Adding Copper Pours

To improve signal integrity and reduce EMI:

- Click on the “Copper Pour” tool in the toolbar.

- Select the desired layer and copper pour properties.

- Define the boundaries of the copper pour using the drawing tools.

- Assign a net name to the copper pour, if applicable.

- Repeat the process for additional copper pours on different layers.

Design Rule Check

Before finalizing your PCB layout, it’s crucial to perform a design rule check (DRC) to ensure that your design meets the manufacturing requirements and design rules.

- Click on “Tools” in the menu bar and select “Design Rule Check.”

- Configure the DRC settings based on your PCB manufacturer’s specifications.

- Run the DRC and review any reported violations.

- Make necessary adjustments to your PCB layout to resolve the violations.

Generating Manufacturing Files

Once your PCB layout is complete and has passed the DRC, you need to generate the manufacturing files required for PCB fabrication.

- Click on “File” in the menu bar and select “Export.”

- Choose the appropriate file formats, such as Gerber files and drill files.

- Specify the output directory and file names.

- Click “Export” to generate the manufacturing files.

Ordering PCBs

With the manufacturing files ready, you can now order your PCBs from a PCB manufacturer.

- Research and select a reputable PCB manufacturer that meets your requirements.

- Provide the generated manufacturing files to the PCB manufacturer.

- Specify the desired PCB specifications, such as material, thickness, and surface finish.

- Review and approve the manufacturer’s quotation and place your order.

Troubleshooting Common Issues

During the PCB design process, you may encounter various issues. Here are some common problems and their solutions:

| Issue | Solution |

|---|---|

| Component footprint mismatch | Verify that the component footprint matches the actual component dimensions. |

| Trace width violations | Adjust trace widths to meet the minimum requirements specified by the manufacturer. |

| Unconnected nets | Ensure that all necessary connections are made in the schematic and PCB layout. |

| Clearance violations | Increase the spacing between components and traces to meet the clearance requirements. |

| Incorrect layer assignments | Double-check the layer assignments for components and traces. |

Advanced Features and Techniques

ExpressPCB offers several advanced features and techniques to enhance your PCB design:

- Hierarchical schematics: Use hierarchical schematics to organize complex designs into smaller, more manageable sub-circuits.

- Autorouting: Utilize the autorouting feature to automatically route traces between components based on predefined rules and constraints.

- 3D visualization: Visualize your PCB design in 3D to ensure proper component placement and clearances.

- Design reuse: Create reusable schematic and PCB layout blocks to streamline future projects.

- Simulation and analysis: Integrate with third-party simulation and analysis tools to validate your design’s performance and functionality.

Frequently Asked Questions (FAQ)

-

Q: Can I import schematic and PCB layouts from other software into ExpressPCB?

A: Yes, ExpressPCB supports importing schematic and PCB layouts from various file formats, such as Eagle and KiCad. -

Q: How do I create custom component footprints in ExpressPCB?

A: ExpressPCB provides a footprint editor where you can create custom component footprints by defining the pad sizes, shapes, and dimensions. -

Q: What are the supported PCB layer configurations in ExpressPCB?

A: ExpressPCB supports various PCB layer configurations, ranging from single-sided to multi-layer boards, depending on your design requirements. -

Q: Can I collaborate with team members using ExpressPCB?

A: ExpressPCB does not have built-in collaboration features, but you can share project files and use version control systems like Git to collaborate with team members. -

Q: Are there any limitations on the PCB size and complexity in ExpressPCB?

A: ExpressPCB can handle a wide range of PCB sizes and complexities, but it’s essential to consider the capabilities of your chosen PCB manufacturer when designing your board.

Conclusion

ExpressPCB is a powerful and user-friendly software for designing and manufacturing PCBs. By following this step-by-step tutorial, you can create professional-quality PCBs using ExpressPCB. Remember to carefully design your schematic, create an efficient PCB layout, and adhere to the manufacturing requirements to ensure a successful PCB fabrication process.

With practice and exploration of advanced features, you can unlock the full potential of ExpressPCB and create complex and reliable PCBs for your projects. Don’t hesitate to refer to the ExpressPCB Documentation and seek assistance from the community forums if you encounter any challenges along the way.

Happy PCB designing with ExpressPCB!

No responses yet