Introduction

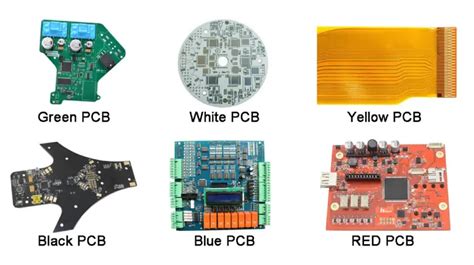

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They provide a platform for electronic components to be mounted and connected, allowing for the creation of complex circuits. One aspect of PCB design that is often overlooked is the color of the PCB. While it may seem like a purely aesthetic choice, the color of a PCB can actually have a significant impact on its functionality, durability, and overall performance.

In this article, we will explore the seven main PCB Colors and discuss how to select the best one for your project. We will also answer some frequently asked questions about PCB colors.

The Importance of PCB Color

Before diving into the specifics of each color, let’s first understand why PCB color matters. Here are a few reasons:

-

Aesthetics: The color of a PCB can enhance the visual appeal of the final product. This is especially important for consumer electronics where aesthetics play a crucial role in the purchasing decision.

-

Functionality: Certain PCB colors can improve the functionality of the board. For example, white PCBs reflect more light, making it easier to inspect the board for defects or solder bridges.

-

Durability: Some PCB colors are more resistant to UV light, moisture, and other environmental factors, which can extend the lifespan of the board.

-

Cost: The cost of a PCB can vary depending on the color. Some colors are more expensive due to the materials and processes involved in their production.

Now that we understand the importance of PCB color, let’s explore the seven main options.

Green PCBs

Green is the most common PCB color and has been the industry standard for decades. Here are some advantages and disadvantages of green PCBs:

Advantages

- Low cost due to mass production

- Good contrast for white silkscreen

- Widely available

Disadvantages

- Can be difficult to inspect for defects

- May not be aesthetically pleasing for some applications

| Property | Value |

|---|---|

| Color | Green |

| Cost | Low |

| Contrast | Good |

Blue PCBs

Blue PCBs are becoming increasingly popular due to their aesthetic appeal and improved functionality. Here are some advantages and disadvantages of blue PCBs:

Advantages

- Visually appealing

- Good contrast for white silkscreen

- Easier to inspect for defects compared to green PCBs

Disadvantages

- More expensive than green PCBs

- May not be as widely available as green PCBs

| Property | Value |

|---|---|

| Color | Blue |

| Cost | High |

| Contrast | Good |

Red PCBs

Red PCBs are less common but can be useful in certain applications. Here are some advantages and disadvantages of red PCBs:

Advantages

- High visual impact

- Can be used for special editions or limited runs

Disadvantages

- More expensive than green and blue PCBs

- Can be difficult to inspect for defects due to low contrast

- May not be widely available

| Property | Value |

|---|---|

| Color | Red |

| Cost | High |

| Contrast | Poor |

Black PCBs

Black PCBs have gained popularity in recent years due to their sleek and modern appearance. Here are some advantages and disadvantages of black PCBs:

Advantages

- Visually striking and modern

- Can enhance the perceived value of the final product

- Good for hiding proprietary circuitry

Disadvantages

- More expensive than green and blue PCBs

- Can be difficult to inspect for defects due to low contrast

- Requires a special solder mask material

| Property | Value |

|---|---|

| Color | Black |

| Cost | High |

| Contrast | Poor |

White PCBs

White PCBs are less common but offer unique advantages in certain applications. Here are some advantages and disadvantages of white PCBs:

Advantages

- Excellent contrast for black silkscreen

- Easy to inspect for defects

- Reflects more light, making it easier to work with

Disadvantages

- More expensive than green and blue PCBs

- Can show dirt and grime more easily

- May require a special solder mask material

| Property | Value |

|---|---|

| Color | White |

| Cost | High |

| Contrast | Great |

Yellow PCBs

Yellow PCBs are relatively rare but can be useful in certain applications. Here are some advantages and disadvantages of yellow PCBs:

Advantages

- High visual impact

- Can be used for special editions or limited runs

Disadvantages

- More expensive than green and blue PCBs

- Can be difficult to inspect for defects due to low contrast

- May not be widely available

| Property | Value |

|---|---|

| Color | Yellow |

| Cost | High |

| Contrast | Poor |

Purple PCBs

Purple PCBs are the least common of the seven main colors but can be used for unique designs. Here are some advantages and disadvantages of purple PCBs:

Advantages

- Visually distinctive

- Can be used for special editions or limited runs

Disadvantages

- More expensive than green and blue PCBs

- Can be difficult to inspect for defects due to low contrast

- May not be widely available

| Property | Value |

|---|---|

| Color | Purple |

| Cost | High |

| Contrast | Poor |

How to Select the Best PCB Color

Now that we’ve explored the seven main PCB colors, how do you select the best one for your project? Here are some factors to consider:

-

Application: Consider the end-use of the PCB. Is it a consumer product where aesthetics are important? Is it an industrial application where durability is critical?

-

Budget: Some PCB colors are more expensive than others. Determine your budget and select a color that fits within it.

-

Availability: Not all PCB manufacturers offer all colors. Check with your manufacturer to see which colors are available.

-

Contrast: Consider the contrast between the PCB color and the silkscreen. Good contrast makes it easier to read component labels and inspect the board for defects.

-

Environmental factors: If the PCB will be exposed to harsh environmental conditions, such as UV light or moisture, select a color that is more resistant to these factors.

FAQ

Q: Are there any other PCB colors besides the seven main ones?

A: Yes, there are other PCB colors available, such as orange, pink, and brown. However, these colors are less common and may be more difficult to source.

Q: Can I mix and match PCB colors in the same design?

A: Yes, you can use different PCB colors in the same design. This can be useful for creating visual contrast or separating different sections of the board.

Q: Do different PCB colors have different electrical properties?

A: No, the color of a PCB does not affect its electrical properties. The electrical performance of a PCB is determined by factors such as the substrate material, copper thickness, and trace geometry.

Q: How does the PCB color affect the manufacturing process?

A: The PCB color can affect the manufacturing process in a few ways. Different colors may require different solder mask materials or processing steps, which can impact the cost and lead time of the PCB.

Q: Can I change the color of an existing PCB design?

A: Yes, you can change the color of an existing PCB design. However, keep in mind that changing the color may require adjustments to the manufacturing process, which could impact the cost and lead time of the PCB.

Conclusion

PCB color is an important consideration in PCB design. It can impact the aesthetics, functionality, durability, and cost of the final product. By understanding the advantages and disadvantages of each color and considering factors such as application, budget, availability, contrast, and environmental conditions, you can select the best PCB color for your project.

Remember, the seven main PCB colors are:

- Green

- Blue

- Red

- Black

- White

- Yellow

- Purple

Each color has its own unique advantages and disadvantages, so choose wisely based on your specific needs and requirements.

No responses yet