Understanding the Basics of a Battery Backup Circuit

Before diving into the construction of a battery backup circuit, it’s essential to understand its basic components and how they work together.

Key Components

- Power Source: The primary power source for the device, such as a wall adapter or a power supply unit (PSU).

- Battery: The secondary power source that takes over when the primary source is unavailable.

- Voltage Regulator: A component that maintains a constant voltage level for the connected device.

- Charging Circuit: A circuit that recharges the battery when the primary power source is available.

- Switching Circuit: A mechanism that switches between the primary and secondary power sources based on availability.

How It Works

When the primary power source is available, it directly powers the connected device while simultaneously charging the battery through the charging circuit. If the primary power fails, the switching circuit automatically switches to the battery, ensuring uninterrupted power to the device. Once the primary power is restored, the switching circuit reverts to the main power source, and the charging circuit begins recharging the battery.

Designing a Battery Backup Circuit

Designing a battery backup circuit requires careful consideration of various factors, such as the power requirements of the connected device, battery capacity, and charging parameters.

Determining Power Requirements

To design an efficient battery backup circuit, you must first determine the power requirements of the connected device. This involves calculating the voltage and current draw of the device under normal operating conditions.

For example, if you’re designing a backup circuit for a 5V device that draws 500mA of current, you’ll need to ensure that your battery and voltage regulator can provide at least 5V and 500mA.

Choosing the Right Battery

The choice of battery depends on several factors, including the power requirements of the connected device, the desired backup duration, and the available space for the battery.

Some common Battery Types used in backup circuits include:

- Lithium-ion (Li-ion) batteries

- Lithium Polymer (LiPo) batteries

- Sealed Lead Acid (SLA) batteries

- Nickel-Metal Hydride (NiMH) batteries

Consider the voltage, capacity (in mAh or Ah), and discharge rate when selecting a battery. Ensure that the battery’s voltage matches the required voltage of your device and that its capacity is sufficient to provide the desired backup duration.

Voltage Regulation

A voltage regulator is necessary to maintain a constant voltage level for the connected device, regardless of the battery’s state of charge. The most common types of voltage regulators used in battery backup circuits are:

- Linear Voltage Regulators: These regulators provide a fixed output voltage and are suitable for low-power applications. Examples include the LM7805 (5V) and LM7812 (12V).

- Switching Voltage Regulators: These regulators are more efficient than linear regulators and can handle higher power levels. They use Pulse-Width Modulation (PWM) to regulate the output voltage. Examples include the LM2596 (adjustable) and the LM2587 (fixed).

Choose a voltage regulator that matches the required output voltage and can handle the current draw of your connected device.

Charging Circuit Design

The charging circuit is responsible for recharging the battery when the primary power source is available. The design of the charging circuit depends on the type of battery used and its charging requirements.

For lithium-based batteries (Li-ion and LiPo), a dedicated lithium battery charging IC, such as the TP4056 or the MCP73831, is recommended. These ICs handle the constant current-constant voltage (CC-CV) charging profile required by lithium batteries and include safety features like overcharge protection.

For other battery types, such as SLA or NiMH, a simple constant voltage-constant current (CV-CC) charging circuit using a voltage regulator and a current-limiting resistor can be used.

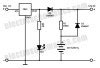

Switching Circuit Design

The switching circuit is responsible for seamlessly switching between the primary and secondary power sources based on availability. This can be achieved using a combination of diodes, transistors, and/or relays.

A simple switching circuit can be constructed using two diodes, one connected to the primary power source and the other to the battery. The diodes ensure that current flows only from the source with the higher voltage, preventing backfeeding.

For more advanced switching circuits, a microcontroller can be used to monitor the primary power source and control the switching process using transistors or relays.

Implementing a Battery Backup Circuit

Now that we’ve covered the design considerations, let’s walk through the steps to implement a basic battery backup circuit.

Step 1: Gather the Required Components

For this example, we’ll create a 5V battery backup circuit using a Li-ion battery. You’ll need the following components:

- 5V power source (e.g., wall adapter or PSU)

- Li-ion battery (e.g., 18650)

- TP4056 lithium battery charging IC

- LM7805 linear voltage regulator

- Two 1N4001 diodes

- 1kΩ resistor

- 10μF capacitor

- Breadboard and jumper wires

Step 2: Connect the Charging Circuit

- Connect the positive terminal of the power source to the VCC pin of the TP4056.

- Connect the negative terminal of the power source to the GND pin of the TP4056.

- Connect the positive terminal of the Li-ion battery to the BAT+ pin of the TP4056.

- Connect the negative terminal of the Li-ion battery to the BAT- pin of the TP4056.

Step 3: Connect the Voltage Regulator

- Connect the positive terminal of the Li-ion battery to the input pin of the LM7805.

- Connect the negative terminal of the Li-ion battery to the ground pin of the LM7805.

- Connect the output pin of the LM7805 to the positive terminal of your connected device.

- Connect the ground pin of the LM7805 to the negative terminal of your connected device.

Step 4: Implement the Switching Circuit

- Connect the anode of one 1N4001 diode to the positive terminal of the power source.

- Connect the anode of the other 1N4001 diode to the positive terminal of the Li-ion battery.

- Connect the cathodes of both diodes together and to the input pin of the LM7805.

Step 5: Add the Filtering Capacitor

- Connect the positive lead of the 10μF capacitor to the output pin of the LM7805.

- Connect the negative lead of the 10μF capacitor to the ground pin of the LM7805.

The filtering capacitor helps to reduce noise and stabilize the output voltage of the regulator.

Testing and Troubleshooting

After completing the implementation, it’s essential to test your battery backup circuit to ensure that it functions as expected.

Testing the Charging Circuit

- Connect the power source to the VCC and GND pins of the TP4056.

- Observe the status LEDs on the TP4056. The red LED should light up, indicating that the battery is charging.

- Once the battery is fully charged, the green LED should light up, and the red LED should turn off.

Testing the Switching Circuit

- With the power source connected, verify that your connected device is receiving power.

- Disconnect the power source and ensure that your device continues to receive power from the battery.

- Reconnect the power source and confirm that the device switches back to the primary power and that the battery begins charging.

Troubleshooting Tips

- Double-check all connections to ensure they are secure and correctly placed.

- Verify that the polarity of the components is correct, especially for the diodes and capacitor.

- Use a multimeter to measure the voltage levels at various points in the circuit to identify any issues.

- If the battery is not charging, check the datasheet of the TP4056 to ensure that the charging parameters are set correctly (e.g., Resistor Values for charge current).

- If the output voltage is unstable or noisy, try increasing the capacitance of the filtering capacitor or adding additional filtering stages.

Advanced Battery Backup Circuit Techniques

While the basic battery backup circuit described above is suitable for many applications, there are several advanced techniques that can be employed to improve efficiency, increase battery life, and add additional features.

Battery Balancing

In multi-cell battery packs, it’s essential to ensure that all cells are charged and discharged evenly to prevent overcharging or over-discharging individual cells, which can lead to reduced battery life or even safety hazards. Battery balancing circuits can be used to monitor and equalize the voltage levels of individual cells in a battery pack.

There are two main types of battery balancing:

- Passive Balancing: This method uses resistors to dissipate excess energy from cells with higher voltages, bringing them in line with the lower-voltage cells. While simple to implement, passive balancing is less efficient and generates heat.

- Active Balancing: This method uses active components, such as transistors or switched capacitors, to transfer energy from higher-voltage cells to lower-voltage cells. Active balancing is more efficient and faster than passive balancing but requires a more complex circuit design.

Low-Voltage Disconnect (LVD)

In battery-powered devices, it’s essential to prevent the battery from being over-discharged, as this can lead to permanent damage or reduced battery life. A low-voltage disconnect (LVD) circuit monitors the battery voltage and disconnects the load when the voltage drops below a predetermined threshold.

A simple LVD circuit can be implemented using a Voltage Comparator, such as the LM393, and a transistor or relay. The comparator monitors the battery voltage and triggers the transistor or relay to disconnect the load when the voltage falls below the set threshold.

Battery State-of-Charge (SoC) Monitoring

Monitoring the state-of-charge (SoC) of a battery can provide valuable information to the user and help prevent unexpected device shutdowns. There are several methods for estimating the SoC of a battery, including:

- Voltage-based SoC Estimation: This method uses the battery voltage to estimate the SoC, based on the known discharge curve of the battery. While simple to implement, voltage-based estimation can be inaccurate due to factors such as temperature and battery age.

- Coulomb Counting: This method involves measuring the current flowing into and out of the battery and integrating it over time to calculate the remaining capacity. Coulomb counting provides more accurate SoC estimation but requires additional hardware, such as a current sensor and a microcontroller.

Implementing SoC monitoring in your battery backup circuit can help users better manage their device usage and plan for recharging.

Energy Harvesting

Energy harvesting involves capturing small amounts of energy from the environment, such as solar, thermal, or kinetic energy, to supplement the battery power in a backup circuit. By incorporating energy harvesting techniques, you can extend the battery life and reduce the frequency of recharging.

Some common energy harvesting methods include:

- Solar Energy Harvesting: Using photovoltaic cells to convert sunlight into electrical energy. This method is suitable for devices that are exposed to sufficient amounts of sunlight.

- Thermoelectric Energy Harvesting: Utilizing the Seebeck effect to generate electricity from temperature gradients. This method can be used in devices that are exposed to heat sources or temperature differences.

- Piezoelectric Energy Harvesting: Converting mechanical stress or strain into electrical energy using piezoelectric materials. This method is suitable for devices that are subjected to vibrations or mechanical motion.

Incorporating energy harvesting into your battery backup circuit requires additional components, such as energy transducers, power management ICs, and storage elements (e.g., supercapacitors).

Battery Backup Circuit Applications

Battery backup circuits find applications in a wide range of devices and systems, ensuring uninterrupted operation and preventing data loss. Some common applications include:

- Uninterruptible Power Supplies (UPS): Battery backup circuits are the core component of UPS systems, providing backup power to critical devices during power outages.

- Wireless Sensors and IoT Devices: Battery backup circuits can be used in wireless sensors and IoT devices to ensure continuous operation and prevent data loss during power failures or when the primary power source is unavailable.

- Medical Devices: Many medical devices, such as patient monitors and infusion pumps, rely on battery backup circuits to ensure uninterrupted operation and patient safety.

- Security Systems: Battery backup circuits are essential in security systems, such as alarm systems and surveillance cameras, to maintain functionality during power outages.

- Industrial Control Systems: In industrial settings, battery backup circuits are used to protect critical control systems and prevent costly downtime due to power failures.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a linear voltage regulator and a switching voltage regulator?

A: Linear voltage regulators provide a fixed output voltage and are suitable for low-power applications, while switching voltage regulators are more efficient and can handle higher power levels. Switching regulators use pulse-width modulation (PWM) to regulate the output voltage. -

Q: How do I determine the capacity of the battery needed for my backup circuit?

A: To determine the required battery capacity, calculate the total current draw of your connected device and multiply it by the desired backup duration. For example, if your device draws 500mA and you want a backup duration of 2 hours, you’ll need a battery with a capacity of at least 1000mAh (500mA × 2h). -

Q: Can I use different types of batteries in my backup circuit?

A: Yes, you can use different types of batteries, such as lithium-ion, lithium polymer, sealed lead acid, or nickel-metal hydride, depending on your specific requirements. However, ensure that you select the appropriate charging and protection circuits for the chosen battery type. -

Q: What is the purpose of the diodes in the switching circuit?

A: The diodes in the switching circuit ensure that current flows only from the source with the higher voltage (either the primary power or the battery) to the load, preventing backfeeding and protecting the components from damage. -

Q: How can I add overcurrent protection to my battery backup circuit?

A: To add overcurrent protection, you can use a resettable fuse (PTC) or a standard fuse in series with the load. These components will limit the current drawn by the load in case of a short circuit or other fault conditions, protecting the battery and other components from damage.

Conclusion

Creating a reliable and efficient battery backup circuit is essential for ensuring uninterrupted power and preventing data loss in various electronic devices. By understanding the basic components, design considerations, and implementation steps, you can create a backup circuit that meets your specific requirements.

Remember to consider factors such as power requirements, battery selection, voltage regulation, charging, and switching when designing your circuit. Additionally, incorporating advanced techniques like battery balancing, low-voltage disconnect, state-of-charge monitoring, and energy harvesting can further improve the performance and reliability of your battery backup system.

As with any electronic project, always prioritize safety and follow best practices when working with batteries and electrical components. By following this comprehensive guide and adapting it to your needs, you’ll be well-equipped to create a robust and dependable battery backup circuit for your next project.

No responses yet