What are PCB Tolerances?

PCB tolerances refer to the acceptable range of variation in the physical dimensions and properties of a printed circuit board (PCB) during the manufacturing process. These tolerances are essential to ensure that the PCB functions as intended and fits properly within the designated enclosure or assembly.

Types of PCB Tolerances

There are several types of tolerances that need to be considered when designing and manufacturing a PCB:

-

Dimensional Tolerances

Dimensional tolerances specify the acceptable range of variation in the physical dimensions of the PCB, such as length, width, and thickness. These tolerances are crucial for ensuring proper fit and compatibility with other components in the assembly.

-

Hole Size Tolerances

Hole size tolerances define the acceptable range of variation in the diameter of drilled holes on the PCB. These holes are used for mounting components, vias, and connectors. Maintaining accurate hole sizes is important for proper component placement and solderability.

-

Copper Thickness Tolerances

Copper thickness tolerances specify the acceptable range of variation in the thickness of the copper layers on the PCB. The copper thickness affects the electrical properties of the PCB, such as current carrying capacity and impedance. Consistent copper thickness is essential for maintaining signal integrity and reliability.

-

Solder Mask Tolerances

Solder mask tolerances define the acceptable range of variation in the application of the solder mask on the PCB. The solder mask is a protective layer that covers the copper traces and prevents short circuits. Accurate solder mask application is crucial for ensuring proper insulation and preventing solder bridging.

-

Silkscreen Tolerances

Silkscreen tolerances specify the acceptable range of variation in the application of the silkscreen layer on the PCB. The silkscreen layer contains text, logos, and component identifiers that aid in assembly and troubleshooting. Maintaining accurate silkscreen placement is important for readability and aesthetics.

Factors Affecting PCB Tolerances

Several factors can influence the achievable tolerances during PCB manufacturing:

-

Manufacturing Process

The manufacturing process used to fabricate the PCB can impact the tolerances. Different processes, such as etching, drilling, and plating, have their own inherent limitations and variances. The choice of manufacturing process should align with the required tolerances for the specific PCB design.

-

Material Properties

The properties of the materials used in PCB fabrication can affect the tolerances. Different substrate materials, such as FR-4, Rogers, or polyimide, have varying dimensional stability, thermal expansion, and mechanical characteristics. The material properties should be considered when specifying tolerances to ensure compatibility and reliability.

-

PCB Complexity

The complexity of the PCB design can impact the achievable tolerances. High-density designs with fine pitch components, small trace widths, and tight spacing require tighter tolerances compared to simpler designs. The complexity of the PCB should be considered when defining tolerance requirements to ensure manufacturability and yield.

-

Manufacturing Equipment

The capabilities and limitations of the manufacturing equipment used can influence the achievable tolerances. The precision and accuracy of the equipment, such as drill machines, etching systems, and inspection tools, determine the level of control over the manufacturing process. Investing in high-quality equipment can help achieve tighter tolerances and improve overall PCB Quality.

Specifying PCB Tolerances

When specifying PCB tolerances, it is important to consider the following guidelines:

-

Industry Standards

Refer to industry standards, such as IPC (Institute for Printed Circuits) standards, for recommended tolerance values based on the PCB class and manufacturing process. IPC Standards provide guidelines for dimensioning, tolerancing, and acceptability criteria for PCBs.

-

Manufacturer Capabilities

Consult with the PCB manufacturer to understand their specific capabilities and limitations in terms of achievable tolerances. Different manufacturers may have varying equipment and processes that affect their ability to meet tight tolerance requirements.

-

Design Requirements

Consider the specific design requirements of the PCB, such as component placement, signal integrity, and mechanical constraints. Define tolerances that align with these requirements to ensure proper functionality and reliability of the PCB.

-

Cost and Lead Time

Tighter tolerances often come with increased manufacturing costs and longer lead times. Strike a balance between the required tolerances and the associated cost and lead time implications. Determine the minimum acceptable tolerances that meet the design requirements while considering budgetary and schedule constraints.

Communicating PCB Tolerances

Effective communication of PCB tolerances is crucial for ensuring a successful manufacturing outcome. Consider the following best practices:

-

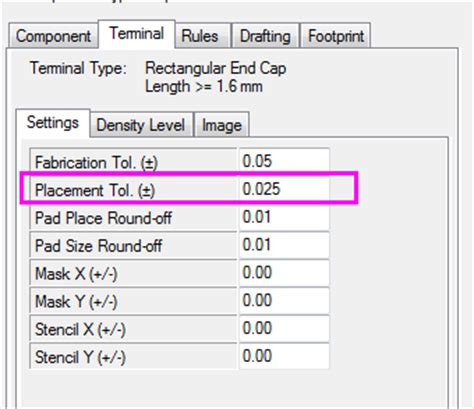

Clearly Document Tolerances

Clearly specify the required tolerances in the PCB design files, fabrication drawings, and manufacturing specifications. Use unambiguous language and provide numerical values for each tolerance parameter.

-

Use Tolerance Stackups

Create tolerance stackups that account for the cumulative effect of tolerances across multiple layers and features of the PCB. Tolerance stackups help identify potential issues and ensure that the overall tolerances are within acceptable limits.

-

Collaborate with Manufacturers

Engage in open communication with the PCB manufacturer throughout the design and manufacturing process. Discuss tolerance requirements, seek their input on achievability, and make necessary adjustments based on their feedback.

-

Conduct Design Reviews

Perform thorough design reviews to validate the specified tolerances and ensure they are appropriate for the intended application. Involve stakeholders from different disciplines, such as electrical, mechanical, and manufacturing, to identify any potential issues or conflicts.

PCB Tolerance Tables

To help visualize and communicate PCB tolerances, it is useful to create tables that summarize the tolerance values for different parameters. Here are a few examples:

Dimensional Tolerances

| Parameter | Nominal Value | Tolerance |

|---|---|---|

| Length | 100 mm | ± 0.5 mm |

| Width | 50 mm | ± 0.5 mm |

| Thickness | 1.6 mm | ± 0.1 mm |

Hole Size Tolerances

| Hole Type | Nominal Size | Tolerance |

|---|---|---|

| Through Hole | 0.8 mm | ± 0.05 mm |

| Via | 0.3 mm | ± 0.03 mm |

| Mounting Hole | 3.0 mm | ± 0.1 mm |

Copper Thickness Tolerances

| Copper Layer | Nominal Thickness | Tolerance |

|---|---|---|

| Outer Layer | 1.0 oz (35 μm) | ± 10% |

| Inner Layer | 0.5 oz (18 μm) | ± 10% |

Solder Mask Tolerances

| Parameter | Nominal Value | Tolerance |

|---|---|---|

| Solder Mask Clearance | 0.1 mm | ± 0.05 mm |

| Solder Mask Thickness | 0.025 mm | ± 0.005 mm |

Frequently Asked Questions (FAQ)

-

Q: What are the consequences of not meeting PCB tolerances?

A: Not meeting PCB tolerances can lead to various issues, such as poor component fit, signal integrity problems, reduced reliability, and assembly difficulties. It can result in increased manufacturing costs, delays, and potential product failures. -

Q: How can I ensure that my PCB design meets the required tolerances?

A: To ensure your PCB design meets the required tolerances, follow these steps: - Clearly define and document the tolerance requirements in your design files and specifications.

- Consult with the PCB manufacturer to understand their capabilities and limitations.

- Use industry standards, such as IPC standards, as a reference for recommended tolerance values.

- Perform thorough design reviews to validate the specified tolerances.

-

Collaborate with the manufacturer throughout the design and manufacturing process.

-

Q: What is the impact of tighter tolerances on PCB cost and lead time?

A: Tighter tolerances generally increase the manufacturing cost and lead time of a PCB. Achieving tighter tolerances requires more precise manufacturing processes, specialized equipment, and additional quality control measures. It is important to find a balance between the required tolerances and the associated cost and schedule implications. -

Q: How do I communicate PCB tolerances effectively to the manufacturer?

A: To communicate PCB tolerances effectively to the manufacturer: - Clearly specify the tolerances in the design files, fabrication drawings, and manufacturing specifications.

- Use unambiguous language and provide numerical values for each tolerance parameter.

- Create tolerance stackups to account for the cumulative effect of tolerances across multiple layers and features.

-

Engage in open communication with the manufacturer and seek their input on achievability.

-

Q: Can PCB tolerances be adjusted during the manufacturing process?

A: PCB tolerances are typically defined during the design phase and should be adhered to during manufacturing. Adjusting tolerances during the manufacturing process is generally not recommended, as it can impact the functionality, reliability, and compatibility of the PCB. If changes to tolerances are necessary, they should be properly evaluated, documented, and communicated to all relevant stakeholders.

Conclusion

Understanding and properly specifying manufacturing tolerances is critical for ensuring the successful fabrication and performance of a PCB. PCB tolerances encompass various aspects, including dimensional, hole size, copper thickness, solder mask, and silkscreen tolerances. Factors such as the manufacturing process, material properties, PCB complexity, and manufacturing equipment capabilities influence the achievable tolerances.

To effectively manage PCB tolerances, it is important to refer to industry standards, consult with manufacturers, consider design requirements, and communicate tolerances clearly. Creating tolerance tables and using tolerance stackups can aid in visualizing and communicating tolerance requirements.

By properly defining, communicating, and managing PCB tolerances, designers and manufacturers can collaborate effectively to produce high-quality and reliable PCBs that meet the desired specifications and performance criteria.

No responses yet