The History of PCBs

The development of PCBs can be traced back to the early 20th century. In 1903, Albert Hanson, a German inventor, filed a patent for a method of creating an electrical connection by bonding a conductive material onto an insulating base. This laid the foundation for the concept of printed wiring.

In the 1920s, Charles Ducas, an American inventor, created a method for electroplating circuit patterns onto an insulated surface. This process, known as the “printed wire process,” was a precursor to modern PCB manufacturing techniques.

During World War II, the demand for compact and reliable electronic equipment led to further advancements in PCB technology. In the 1940s, Paul Eisler, an Austrian engineer, developed a method for etching conductive pathways onto a non-conductive base material. This technique, known as the “printed circuit process,” revolutionized the electronics industry and paved the way for the mass production of PCBs.

Timeline of PCB Development

| Year | Development |

|---|---|

| 1903 | Albert Hanson patents a method for creating electrical connections on an insulating base |

| 1920s | Charles Ducas develops the “printed wire process” |

| 1940s | Paul Eisler develops the “printed circuit process” |

| 1950s | PCBs become widely used in the electronics industry |

| 1960s | Multi-layer PCBs are introduced |

| 1980s | Surface-mount technology (SMT) becomes popular |

| 1990s | High-density interconnect (HDI) PCBs are developed |

| 2000s | Flexible and Rigid-Flex PCBs gain popularity |

Types of PCBs

There are several types of PCBs, each designed to meet specific requirements and applications. The most common types include:

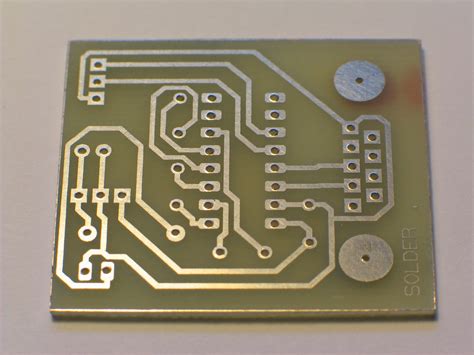

1. Single-Layer PCBs

Single-layer PCBs, also known as Single-Sided PCBs, have conductive traces on only one side of the insulating substrate. These boards are the simplest and most cost-effective type of PCB, making them ideal for basic electronic projects and low-density designs.

2. Double-Layer PCBs

Double-layer PCBs, or double-sided PCBs, have conductive traces on both sides of the insulating substrate. The two layers are connected using through-hole technology, which involves drilling holes through the board and plating them with conductive material. Double-layer PCBs offer higher component density and more complex routing options compared to single-layer PCBs.

3. Multi-Layer PCBs

Multi-layer PCBs consist of three or more conductive layers separated by insulating layers. These boards are designed for complex electronic systems that require high component density and intricate interconnections. The layers are connected using through-holes or blind and buried vias, which are drilled and plated holes that connect specific layers without going through the entire board.

4. Flexible PCBs

Flexible PCBs, or flex circuits, are made using flexible insulating materials, such as polyimide or polyester. These boards can bend and flex without damaging the conductive traces, making them ideal for applications that require non-planar or movable connections, such as wearable electronics and aerospace systems.

5. Rigid-Flex PCBs

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs. These boards have rigid sections for mounting components and flexible sections for connecting the rigid sections or for routing in tight spaces. Rigid-flex PCBs are commonly used in medical devices, automotive electronics, and aerospace applications.

PCB Manufacturing Process

The PCB manufacturing process involves several steps, each critical to ensuring the quality and reliability of the final product. The main steps include:

1. Design and Layout

The first step in PCB manufacturing is designing the circuit schematic and creating the PCB layout using computer-aided design (CAD) software. The layout determines the placement of components and the routing of conductive traces on the board.

2. Substrate Preparation

The insulating substrate, typically made of fiberglass or composite epoxy, is cut to the desired size and shape. Copper foil is then laminated onto one or both sides of the substrate using heat and pressure.

3. Printing and Etching

The PCB layout is printed onto the copper-clad substrate using a photoresist process. The board is then exposed to UV light, which hardens the photoresist in the areas that will become the conductive traces. The unexposed photoresist is removed, and the board is etched using a chemical solution that dissolves the unwanted copper, leaving only the desired conductive traces.

4. Drilling

Holes are drilled through the board to accommodate through-hole components and to create vias for interconnecting layers in multi-layer PCBs. The holes are then plated with conductive material to ensure electrical continuity.

5. Solder Mask Application

A solder mask, a protective layer of polymer material, is applied to the board’s surface. The solder mask covers the conductive traces, leaving only the areas intended for component soldering exposed. This layer helps prevent short circuits and improves the board’s durability.

6. Silkscreen Printing

A silkscreen layer is printed onto the board to add labels, logos, and other identifying markings. This layer helps with component placement and makes the board easier to assemble and troubleshoot.

7. Surface Finish Application

A surface finish, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative), is applied to the exposed copper areas to prevent oxidation and improve solderability.

8. Electrical Testing

The completed PCB undergoes electrical testing to ensure that all connections are properly formed and that there are no short circuits or open connections. This step is critical for ensuring the board’s functionality and reliability.

PCB Design Considerations

When designing a PCB, several factors must be considered to ensure optimal performance and manufacturability. Some key considerations include:

1. Component Placement

Components should be placed in a logical and efficient manner, minimizing the distance between connected components and reducing the overall board size. Proper component placement also helps with heat dissipation and improves the board’s mechanical stability.

2. Trace Width and Spacing

The width and spacing of conductive traces must be carefully designed to ensure proper current-carrying capacity and to minimize electromagnetic interference (EMI). Trace width and spacing also affect the board’s impedance, which is critical for high-speed and high-frequency designs.

3. Via Placement and Size

Vias should be placed strategically to minimize the distance between layers and to improve signal integrity. The size of the vias must be carefully chosen based on the current-carrying requirements and the available board space.

4. Power and Ground Planes

Proper power and ground plane design is essential for minimizing noise and ensuring stable power delivery to all components. The planes should be designed to provide low-impedance paths for current flow and to minimize voltage drops across the board.

5. Thermal Management

Proper thermal management is critical for ensuring the long-term reliability of the PCB and its components. This can be achieved through the use of thermal vias, heat sinks, and proper component placement to facilitate heat dissipation.

PCB Testing and Inspection

To ensure the quality and reliability of PCBs, various testing and inspection methods are employed throughout the manufacturing process and after the boards are assembled. Some common testing and inspection techniques include:

1. Visual Inspection

Visual inspection is the most basic form of PCB testing, involving a thorough examination of the board for any visible defects, such as scratches, cracks, or discolorations. This can be done manually or using automated optical inspection (AOI) systems.

2. X-Ray Inspection

X-ray inspection is used to examine the internal structure of the PCB, particularly for multi-layer boards and boards with hidden or buried components. This technique can detect issues such as voids in solder joints, misaligned components, and internal delamination.

3. In-Circuit Testing (ICT)

In-circuit testing involves using a bed-of-nails fixture to make electrical contact with specific points on the PCB. This allows for the testing of individual components and the verification of their values and functionality. ICT is particularly useful for detecting component-level faults and ensuring that the board is assembled correctly.

4. Functional Testing

Functional testing involves powering up the PCB and testing its overall functionality. This can be done using custom test fixtures or by connecting the board to its intended system. Functional testing helps ensure that the board performs as expected and meets the required specifications.

5. Boundary Scan Testing

Boundary scan testing, also known as JTAG testing, is a method for testing the interconnections between components on a PCB. This technique uses a special test access port (TAP) to control and monitor the inputs and outputs of individual components, allowing for the detection of short circuits, open connections, and other faults.

Applications of PCBs

PCBs are used in virtually every electronic device, from simple toys to complex aerospace systems. Some common applications include:

1. Consumer Electronics

PCBs are the backbone of consumer electronic devices, such as smartphones, tablets, laptops, and televisions. They enable the compact and efficient packaging of complex electronic circuits, allowing for the development of ever-smaller and more powerful devices.

2. Automotive Electronics

Modern vehicles rely heavily on electronic systems for engine control, safety features, and infotainment. PCBs are used in a wide range of automotive applications, including engine control units (ECUs), anti-lock braking systems (ABS), and in-vehicle entertainment systems.

3. Medical Devices

PCBs are essential components in various medical devices, such as patient monitors, imaging equipment, and implantable devices. The reliability and precision of PCBs are critical in these applications, as they directly impact patient safety and treatment outcomes.

4. Aerospace and Defense

PCBs used in aerospace and defense applications must meet stringent requirements for reliability, durability, and performance under extreme conditions. These boards are often designed to withstand high temperatures, vibration, and exposure to harsh environmental factors.

5. Industrial Automation

PCBs play a crucial role in industrial automation systems, such as programmable logic controllers (PLCs), sensors, and actuators. These boards must be designed to operate reliably in harsh industrial environments and to interface with a wide range of equipment and protocols.

Future Trends in PCB Technology

As electronic devices continue to evolve and become more complex, PCB technology must adapt to meet new challenges and demands. Some emerging trends in PCB technology include:

1. High-Density Interconnect (HDI)

HDI PCBs feature finer trace widths, smaller vias, and higher component densities compared to traditional PCBs. This technology enables the development of more compact and powerful electronic devices, particularly in the consumer electronics and wearables sectors.

2. Embedded Components

Embedded component technology involves placing components, such as resistors and capacitors, within the layers of a multi-layer PCB. This approach saves space on the board surface and improves signal integrity by reducing the distance between components.

3. 3D Printing

3D printing technology is being explored as a potential method for PCB fabrication. This approach could enable the rapid prototyping of complex PCB designs and the creation of non-planar and multi-functional structures.

4. Flexible and Stretchable Electronics

The development of flexible and stretchable PCBs is opening up new possibilities for wearable and implantable electronic devices. These boards can conform to the shape of the human body and withstand the stresses of movement and flexing.

5. Environmentally Friendly Materials

As environmental concerns continue to grow, there is an increasing demand for PCBs made from eco-friendly materials. This includes the use of halogen-free flame retardants, lead-free solders, and biodegradable substrates.

Frequently Asked Questions (FAQ)

-

What is the difference between a PCB and a Printed Wiring Board (PWB)?

A PCB and a PWB are essentially the same things. The term “printed wiring board” was more commonly used in the past, but “printed circuit board” has become the more prevalent term in recent years. -

Can PCBs be repaired if they are damaged?

In some cases, PCBs can be repaired if the damage is limited to a small area and does not affect multiple layers or components. However, attempting to repair a PCB can be risky and may result in further damage if not done properly. In many cases, it is more cost-effective and reliable to replace the damaged board entirely. -

What is the typical lifespan of a PCB?

The lifespan of a PCB depends on various factors, such as the quality of the materials used, the manufacturing process, and the operating environment. In general, a well-designed and manufactured PCB can last for several decades under normal operating conditions. However, exposure to extreme temperatures, humidity, or other harsh environmental factors can significantly reduce a PCB’s lifespan. -

What is the difference between surface-mount and through-hole components?

Surface-mount components are designed to be soldered directly onto the surface of a PCB, while through-hole components have leads that are inserted into holes drilled through the board and soldered on the opposite side. Surface-mount components are generally smaller and enable higher component densities, while through-hole components are often used for larger or higher-power components and provide stronger mechanical connections. -

What is the role of a solder mask on a PCB?

A solder mask is a protective layer applied to the surface of a PCB that covers the conductive traces, leaving only the areas intended for component soldering exposed. The solder mask helps prevent short circuits by insulating the traces from accidental contact and also protects the board from environmental factors such as dust, moisture, and abrasion. Additionally, the solder mask improves the board’s aesthetic appearance and makes it easier to identify component placement locations.

In conclusion, PCBs are essential components in modern electronic devices, enabling the compact and efficient packaging of complex circuits. Understanding the history, types, manufacturing process, design considerations, and testing methods of PCBs is crucial for anyone involved in the development or production of electronic systems. As technology continues to advance, PCB design and manufacturing will evolve to meet the ever-increasing demands for smaller, faster, and more reliable electronic devices.

No responses yet