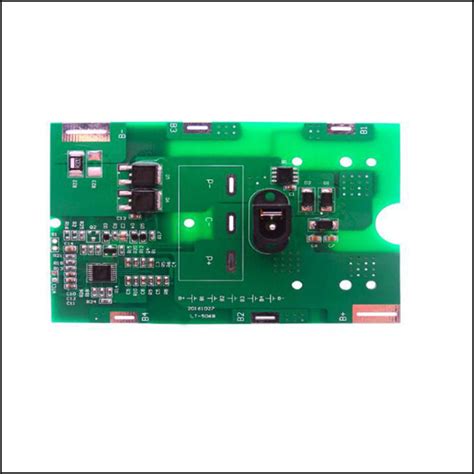

Introduction to Lithium Battery PCBs in Electric Vehicles

The rise of electric vehicles (EVs) has revolutionized the automotive industry, offering a cleaner and more efficient alternative to traditional gasoline-powered cars. At the heart of every EV lies a sophisticated lithium battery system, which relies on advanced printed circuit boards (PCBs) to manage power distribution, charging, and monitoring. In this comprehensive guide, we will delve into the world of lithium battery PCBs for electric cars, exploring their key components, design considerations, manufacturing processes, and future trends.

The Role of PCBs in Lithium Battery Systems

Lithium battery PCBs play a crucial role in the overall performance and safety of electric vehicles. These specialized circuit boards are responsible for several critical functions:

-

Power Distribution: The PCB acts as a central hub for distributing electrical power from the lithium battery pack to various components of the electric vehicle, such as the electric motor, onboard charger, and auxiliary systems.

-

Battery Management System (BMS): Integrated into the PCB, the BMS monitors and controls the charging and discharging of individual battery cells, ensuring optimal performance and preventing overcharging or undercharging, which can lead to battery degradation or even catastrophic failure.

-

Cell Balancing: The PCB incorporates cell balancing circuits that maintain an equal voltage across all cells in the battery pack, maximizing the overall capacity and extending the lifespan of the battery.

-

Thermal Management: Temperature sensors and control circuits on the PCB monitor and regulate the temperature of the battery pack, preventing overheating and ensuring safe operation in various environmental conditions.

-

Communication and Diagnostics: The PCB facilitates communication between the battery system and other vehicle components, such as the motor controller and the vehicle’s central computer, allowing for real-time monitoring, diagnostics, and fault detection.

Key Components of Lithium Battery PCBs

A typical lithium battery PCB consists of several essential components that work together to ensure the safe and efficient operation of the battery system. These components include:

-

Microcontroller: The brain of the battery management system, the microcontroller executes the BMS firmware and communicates with other vehicle systems.

-

Voltage and Current Sensing Circuits: These circuits monitor the voltage and current of individual battery cells and the overall battery pack, providing crucial data for the BMS to make informed decisions.

-

Cell Balancing Circuits: Passive or active cell balancing circuits ensure that all cells in the battery pack maintain an equal voltage, preventing overcharging or undercharging of individual cells.

-

Temperature Sensors: Strategically placed temperature sensors monitor the thermal condition of the battery pack, allowing the BMS to adjust charging and discharging parameters to prevent overheating.

-

Power Switches: High-current power switches, such as MOSFETs or relays, control the flow of electrical power between the battery pack and the vehicle’s electrical systems.

-

Communication Interfaces: Various communication interfaces, such as CAN bus, I2C, or SPI, enable data exchange between the battery PCB and other vehicle components.

-

Protective Circuits: Fuses, circuit breakers, and other protective devices safeguard the battery system against short circuits, overloads, and other electrical faults.

PCB Design Considerations for Lithium Battery Systems

Designing a lithium battery PCB for electric vehicles involves several critical considerations to ensure optimal performance, reliability, and safety. Some of the key design factors include:

-

High Voltage and Current Handling: Lithium battery PCBs must be designed to handle high voltages (typically 300V to 800V) and currents (up to several hundred amps) associated with EV battery packs. This requires careful selection of PCB materials, trace widths, and copper weights to minimize voltage drops and resistive losses.

-

Thermal Management: Efficient heat dissipation is crucial for the longevity and safety of lithium battery systems. PCB designers must incorporate adequate thermal relief, heat sinks, and cooling mechanisms to prevent overheating of components and ensure even temperature distribution across the board.

-

EMI/EMC Compliance: Electric vehicles are subject to stringent electromagnetic compatibility (EMC) regulations to minimize electromagnetic interference (EMI) with other vehicle systems and external devices. PCB designers must implement proper shielding, grounding, and filtering techniques to meet these requirements.

-

Vibration and Shock Resistance: Lithium battery PCBs in EVs are exposed to constant vibration and occasional shocks during vehicle operation. The PCB must be designed with robust mechanical support, using reinforced mounting points, stiffeners, and shock-absorbing materials to withstand these stresses.

-

Serviceability and Modularity: As EV battery packs are often designed for serviceability and upgradability, the PCB layout should facilitate easy access to key components, such as fuses, connectors, and sensors. Modular designs allow for the replacement of individual battery modules without requiring a complete system overhaul.

-

Cost Optimization: With the increasing demand for affordable electric vehicles, PCB designers must strike a balance between performance, reliability, and cost. This involves optimizing the board layout, minimizing the number of layers, and selecting cost-effective components without compromising on quality or safety.

Manufacturing and Assembly of Lithium Battery PCBs

The manufacturing and assembly process for lithium battery PCBs involves several critical steps to ensure the highest quality and reliability:

-

PCB Fabrication: High-quality PCB substrates, such as FR-4 or polyimide, are used to fabricate the circuit board. The board undergoes a series of processes, including copper etching, drilling, plating, and Solder Mask Application, to create the desired circuit pattern.

-

Component Placement: Surface-mount technology (SMT) and through-hole mounting techniques are used to place components on the PCB. Automated pick-and-place machines ensure precise and consistent component placement, minimizing the risk of assembly errors.

-

Soldering: Reflow Soldering is the preferred method for SMT Components, while wave soldering is used for through-hole components. Strict temperature profiles and process controls are maintained to ensure reliable solder joints and prevent thermal damage to components.

-

Conformal Coating: To protect the PCB and its components from moisture, dust, and chemical contamination, a conformal coating is applied. This thin, protective layer enhances the board’s durability and long-term reliability in the harsh automotive environment.

-

Testing and Inspection: Rigorous testing and inspection procedures are employed to verify the functionality, performance, and safety of the lithium battery PCB. This includes Automated Optical Inspection (AOI), in-circuit testing (ICT), and functional testing to identify any manufacturing defects or performance issues.

-

Traceability and Documentation: Each PCB is assigned a unique serial number or barcode for traceability throughout the manufacturing process and the product’s lifecycle. Detailed documentation, including bill of materials (BOM), assembly drawings, and test reports, is maintained for quality control and regulatory compliance.

Future Trends in Lithium Battery PCBs for Electric Vehicles

As the demand for electric vehicles continues to grow, lithium battery PCB technology is evolving to meet the increasing performance, safety, and sustainability requirements. Some of the notable trends shaping the future of lithium battery PCBs include:

-

High-Voltage Systems: The push for longer driving ranges and faster charging times is driving the development of higher-voltage battery systems, with some EVs adopting 800V or even 1000V architectures. PCB designers must adapt to these higher voltage levels, ensuring adequate insulation, creepage, and clearance distances.

-

Wireless BMS: The integration of wireless communication technologies, such as Bluetooth or Wi-Fi, into battery management systems enables real-time monitoring and control of battery performance without the need for physical wiring. This simplifies the PCB layout and reduces the overall weight of the battery pack.

-

Flexible and Printed Electronics: The advent of flexible PCB materials and printed electronics technology opens up new possibilities for battery pack design. Conformable PCBs can be integrated into the battery enclosure, saving space and enabling more compact and lightweight battery systems.

-

Recycling and Sustainability: As the first generation of EV batteries approaches the end of their lifespan, there is a growing emphasis on recyclability and sustainability. PCB designers are exploring the use of eco-friendly materials, such as halogen-free laminates and lead-free solders, to facilitate the recycling process and minimize environmental impact.

-

Artificial Intelligence and Machine Learning: The integration of AI and machine learning algorithms into battery management systems enables predictive maintenance, real-time optimization of charging and discharging parameters, and more accurate state-of-charge (SoC) and state-of-health (SoH) estimation. This enhances the overall performance, safety, and longevity of the battery system.

Frequently Asked Questions (FAQ)

-

What is the typical voltage range for lithium battery PCBs in electric vehicles?

Lithium battery PCBs in electric vehicles typically handle voltages ranging from 300V to 800V, depending on the specific battery pack design and vehicle requirements. Some high-performance EVs are moving towards even higher voltages, such as 1000V, to enable faster charging and improved performance. -

How does the battery management system (BMS) ensure the safety of the lithium battery pack?

The BMS continuously monitors the voltage, current, and temperature of individual battery cells and the overall battery pack. It uses this data to control the charging and discharging process, preventing overcharging, undercharging, and overheating. The BMS also incorporates safety features, such as short-circuit protection, overcurrent protection, and thermal shutdown, to prevent catastrophic failures. -

What are the key considerations when designing a lithium battery PCB for vibration and shock resistance?

To ensure vibration and shock resistance, PCB designers must incorporate robust mechanical support features, such as reinforced mounting points, stiffeners, and shock-absorbing materials. The PCB layout should also minimize the stress on components by using proper component placement, orientation, and strain relief techniques. Additionally, the use of conformal coating helps to dampen vibrations and protect components from mechanical damage. -

How can PCB designers optimize the thermal management of lithium battery systems?

Effective thermal management is crucial for the performance and longevity of lithium battery PCBs. Designers can optimize thermal management by incorporating adequate thermal relief, such as heat sinks, thermal vias, and cooling channels, to dissipate heat from critical components. The PCB layout should also promote even heat distribution and minimize thermal hotspots. The use of temperature sensors and active cooling systems, such as fans or liquid cooling, can further enhance thermal management. -

What are the benefits of using flexible PCBs in lithium battery systems for electric vehicles?

Flexible PCBs offer several advantages for lithium battery systems in electric vehicles. They can conform to the shape of the battery enclosure, enabling more compact and lightweight battery pack designs. Flexible PCBs also provide improved vibration and shock resistance, as they can absorb mechanical stresses better than rigid PCBs. Additionally, the use of flexible PCBs can simplify the assembly process and reduce the number of interconnects, improving overall system reliability.

Conclusion

Lithium battery PCBs play a critical role in the performance, safety, and reliability of electric vehicles. As the demand for EVs continues to grow, PCB designers and manufacturers must stay at the forefront of technological advancements to meet the evolving requirements of the automotive industry. By understanding the key components, design considerations, manufacturing processes, and future trends in lithium battery PCBs, engineers can develop innovative solutions that drive the widespread adoption of electric vehicles and contribute to a more sustainable future.

No responses yet