Why Transition from Gerber to IPC-2581 for PCB Design Files?

Printed circuit board (PCB) design and manufacturing has relied on the Gerber file format for decades as the de facto standard for transferring PCB design data. Developed in the 1960s, Gerber has limitations in conveying the increasingly complex information needed for modern, high-density PCB designs and automated manufacturing processes. To address these shortcomings, the electronics industry developed the IPC-2581 standard as a intelligent, comprehensive format to replace Gerber.

Limitations of Gerber Files for Modern PCB Designs

While Gerber files have been widely used, they have several drawbacks:

- Lack of a full intelligent data model with net and component info

- No standardized way to include stackup, materials, design intent

- Risk of manual errors when generating multiple Gerber files

- No clear single master format between manufacturer and designer

These issues make the PCB design to manufacturing hand-off inefficient and error-prone, leading to delays and higher costs. IPC-2581 aims to solve these problems.

IPC-2581 Benefits and Advantages

IPC-2581 is an open, vendor-neutral format based on XML that provides a complete PCB “product model” with everything needed for manufacturing:

- Single file contains all stackup, netlist, BOM, layer, drilling data

- Semantic netlist to clearly convey design intent and rules

- Support for embedded components and complex structures

- Human and machine readable for easy parsing and processing

By transitioning to IPC-2581, PCB designers and manufacturers can streamline the data exchange, reduce manual re-entry of data, and improve overall efficiency. It enables a shift to fully digital models and smart manufacturing.

How to Convert PCB Designs from Gerber to IPC-2581

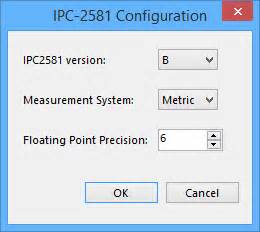

Most major PCB design tools now support exporting to IPC-2581 format. The basic process involves:

- Complete your PCB design layout as usual in the CAD software

- Instead of generating Gerber files, choose to export IPC-2581

- Select the export options to include in the IPC-2581 file:

- Stackup information

- Net and component data

- Design rules and constraints

- Layer images and drill data

- Verify the generated IPC-2581 using a viewer tool

- Send the single IPC-2581 file to your manufacturer

Many PCB Manufacturers are now encouraging customers to switch to IPC-2581 files instead of Gerber. They can directly read the intelligent product model into their CAM and CAD/CAM software.

PCB CAD Software with IPC-2581 Export

| CAD Tool | Export Steps |

|---|---|

| Altium Designer | File > Fabrication Outputs > IPC-2581 |

| Cadence Allegro | File > Export > IPC-2581 |

| Mentor PADS | File > Export > IPC-2581 |

| Zuken CR-8000 | Output Menu > IPC-2581 |

*Check with your specific PCB CAD tool vendor for detailed export settings and options. Some may require downloading extensions or plugins.

Industry Adoption and Advantages of IPC-2581

The use of IPC-2581 is growing among both PCB design and manufacturing companies. Adopting the intelligent format provides advantages for all stakeholders:

PCB Designers

- Simplified data hand-off to manufacturing

- Clearer communication of design intent

- Fewer delays from data inconsistencies

- Greater confidence in manufacturability

PCB Manufacturers

- Richer, machine-readable product model data

- Elimination of manual data re-entry

- Faster new product introduction (NPI)

- Foundation for Industry 4.0 smart automation

Major companies like Intel, Lockheed Martin, Northrop Grumman, and Raytheon have spearheaded IPC-2581 working groups. PCB manufacturers including Sanmina, Zentech, Tempo Automation, and more are actively promoting the use of the standard.

Compliance with Defense and Aerospace Requirements

For companies serving highly-regulated industries like defense and aerospace, IPC-2581 is becoming a requirement to do business. The U.S. Department of Defense has stated goals to move all PCB technical data packages to the IPC-2581 format by 2023. This is part of wider efforts to modernize Electronics Manufacturing with digital data models and advanced automation under the DoD Digital Engineering Strategy.

Overcoming Barriers to IPC-2581 Adoption

While IPC-2581 offers compelling benefits, there are still challenges that may slow its adoption as a total replacement for Gerber, including:

- Legacy Processes and Resistance to Change

- Comfort with Gerber as “known” incumbent

- Disruption to existing workflows and interfaces

- Need for education and updated training

- Inconsistent Software Implementations

- Varying support for IPC-2581 export options

- Lack of mature viewing/proofing tools

- Incomplete documentation and examples

- Perception of Higher Costs

- Need to upgrade or change software

- Time/effort for re-validation of processes

- Uncertain ROI and benefits

Overcoming these barriers will require leadership and collaboration across the electronics industry. PCB designers, manufacturers, and software vendors need to align on implementation and invest in the necessary tools and training. Having clear guidance and case studies demonstrating the benefits of IPC-2581 will accelerate adoption.

FAQs on Replacing Gerber with IPC-2581

What is the status of IPC-2581 as an official standard?

IPC-2581 was developed by the IPC D-33a subcommittee with input from a broad group of industry stakeholders. It was initially released in 2004 and has undergone several revisions to expand capabilities, with Revision C being the latest version. While it is an IPC standard, it is not yet widely mandated like Gerber. Adoption is voluntary but growing.

Is IPC-2581 compatible with my existing PCB design software?

Most of the major PCB CAD tools have added support for exporting to IPC-2581 format. However, the specific options and level of support can vary between different software vendors and versions. It’s best to check with your CAD tool vendor on their roadmap for IPC-2581 and any updates or plugins that may be required.

Will using IPC-2581 cost more than Gerber?

Transitioning to IPC-2581 does not inherently cost more than using Gerber. The main potential costs would be upgrading any software tools to versions that support IPC-2581 and the time for learning the new format. However, these can be offset by efficiency gains and cost savings from reducing manual data entry, design revisions, and manufacturing issues.

How can I validate an IPC-2581 file before sending for manufacturing?

Several free IPC-2581 viewer tools are available to open and inspect the contents of the file. These let you see the stackup, netlist, drill data, and layer images to verify all the needed manufacturing data is correctly included. Some PCB design tools also have built-in IPC-2581 export validation. Discussing file requirements proactively with your manufacturer is also recommended.

Where can I find more information and resources on IPC-2581?

The official IPC-2581 Consortium website (www.ipc2581.com) provides an overview of the standard, technical documentation, and links to supportive industry partners. For practical guidance, the IPC-2581 Handbook from IPC is a helpful resource. PCB design blogs and forums can also provide tips from engineers and designers who have experience implementing IPC-2581.

Conclusion

PCB designers and manufacturers that adopt the intelligent IPC-2581 format to replace traditional Gerber files can achieve significant benefits in efficiency, quality, and automation. As the electronics industry advances with more complex products and digital processes, using a complete, machine-readable PCB product model will be essential. Though barriers remain, the transition from Gerber to IPC-2581 is a necessary evolution for the future of PCB design and manufacturing.

No responses yet