Introduction to PCB vs Breadboard

When it comes to electronic prototyping and circuit design, two of the most commonly used tools are PCBs (Printed Circuit Boards) and breadboards. While both serve the purpose of connecting electronic components, they have distinct differences in terms of their design, functionality, and applications. In this article, we will explore the key differences between PCBs and breadboards, their advantages and disadvantages, and when to use each one.

What is a PCB?

A Printed Circuit Board (PCB) is a flat board made of insulating material, typically fiberglass or composite epoxy, with conductive copper traces printed on its surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits (ICs), to form a complete circuit. PCBs are designed using specialized software and are manufactured through a multi-step process involving etching, drilling, and plating.

Advantages of PCBs

- Durability: PCBs are sturdy and can withstand harsh environmental conditions, making them suitable for long-term use in various applications.

- Compact design: PCBs allow for a high density of components to be placed in a small area, resulting in compact and efficient circuit designs.

- Reliability: The fixed connections on a PCB ensure a reliable and stable circuit, reducing the risk of loose connections or short circuits.

- Mass production: Once a PCB Design is finalized, it can be easily mass-produced, making it cost-effective for large-scale manufacturing.

Disadvantages of PCBs

- Higher initial cost: Designing and manufacturing PCBs require specialized software, equipment, and expertise, resulting in higher upfront costs compared to breadboards.

- Limited flexibility: Once a PCB is manufactured, it is difficult to make changes or modifications to the circuit without redesigning and fabricating a new board.

- Longer development time: The process of designing, prototyping, and manufacturing a PCB can be time-consuming, especially for complex circuits.

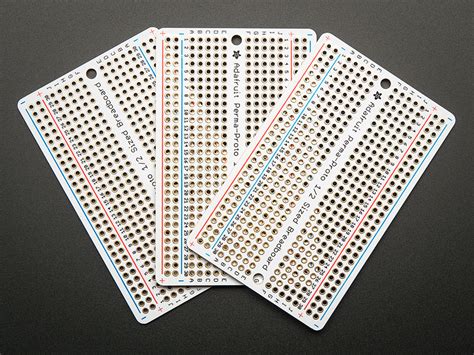

What is a Breadboard?

A breadboard is a rectangular plastic board with a grid of holes used for prototyping electronic circuits. It consists of a series of connected metal clips hidden beneath the plastic surface, allowing components to be easily inserted and removed without the need for soldering. Breadboards are often used for temporary circuit setups, testing, and experimentation.

Advantages of Breadboards

- Easy to use: Breadboards require no soldering, making it simple to insert and remove components, even for beginners.

- Flexibility: Circuits can be quickly modified or reconfigured on a breadboard, allowing for easy experimentation and troubleshooting.

- Reusability: Components can be easily removed from a breadboard and reused in other projects, making it a cost-effective option for prototyping.

- No specialized tools required: Breadboards can be used with basic electronic components and tools, such as jumper wires and a Power Supply.

Disadvantages of Breadboards

- Limited current capacity: Breadboards have a limited current carrying capacity due to the thin metal clips, making them unsuitable for high-power applications.

- Prone to loose connections: The temporary nature of Breadboard Connections can lead to loose or intermittent connections, causing circuit failures or inconsistent behavior.

- Not suitable for permanent installations: Breadboards are designed for temporary prototyping and are not recommended for permanent or long-term installations.

- Limited component density: The physical size of breadboards limits the number of components that can be accommodated, making them less suitable for complex circuits.

PCB vs Breadboard: When to Use Each

The choice between using a PCB or a breadboard depends on various factors, such as the project’s complexity, duration, and purpose. Here are some general guidelines:

When to Use a PCB

- Final product design: If you are designing a circuit for a final product or a permanent installation, a PCB is the preferred choice due to its durability, reliability, and compact size.

- High-frequency or sensitive circuits: PCBs offer better signal integrity and reduced noise compared to breadboards, making them suitable for high-frequency or sensitive analog circuits.

- Mass production: If you plan to manufacture a large number of identical circuits, designing a PCB is more cost-effective and efficient in the long run.

- Harsh environments: PCBs can be designed to withstand extreme temperatures, vibrations, and other environmental factors, making them suitable for use in industrial or outdoor applications.

When to Use a Breadboard

- Prototyping and experimentation: Breadboards are ideal for quickly testing and modifying circuit designs, allowing for easy experimentation and troubleshooting.

- Educational purposes: Breadboards are often used in educational settings to teach electronic concepts and circuit design, as they provide a hands-on learning experience.

- Low-complexity circuits: If your circuit is relatively simple and does not require a high component density, a breadboard can be a suitable choice.

- Temporary setups: Breadboards are useful for temporary circuit setups, such as testing a new component or demonstrating a concept.

Comparing PCB and Breadboard

| Feature | PCB | Breadboard |

|---|---|---|

| Durability | High, suitable for long-term use | Low, prone to wear and tear |

| Flexibility | Low, difficult to modify after manufacturing | High, easy to modify and reconfigure |

| Reliability | High, fixed connections ensure stability | Low, prone to loose or intermittent connections |

| Component Density | High, allows for compact designs | Low, limited by physical size |

| Cost | Higher initial cost, cost-effective for mass production | Lower initial cost, suitable for prototyping |

| Development Time | Longer, involves design and manufacturing process | Shorter, allows for quick prototyping |

| Soldering Required | Yes, components are soldered onto the board | No, components are inserted into the board |

| Suitable Applications | Final products, harsh environments, mass production | Prototyping, education, temporary setups |

FAQs

-

Can I convert a breadboard circuit to a PCB?

Yes, it is possible to convert a breadboard circuit to a PCB. Once you have tested and finalized your circuit on a breadboard, you can design a PCB Layout using specialized software and have it manufactured. -

Are there any alternatives to PCBs and breadboards?

Yes, there are other prototyping methods available, such as stripboards (also known as perfboards), which have pre-drilled holes and copper strips for soldering components. Additionally, wire wrapping is a technique that involves wrapping wires around component leads to create connections. -

Can I use surface-mount components (SMDs) on a breadboard?

While it is possible to use SMDs on a breadboard with the help of adapters or breakout boards, it can be challenging due to the small size of the components. Breadboards are more suitable for through-hole components, which have longer leads that can be easily inserted into the board. -

How do I choose the right size of PCB for my project?

The size of your PCB depends on factors such as the number and size of components, the complexity of the circuit, and the available space in the final product. It’s essential to consider these factors and use PCB design software to create a compact and efficient layout. -

Can I reuse a PCB in multiple projects?

Unlike breadboards, where components can be easily removed and reused, PCBs are designed for a specific circuit and are not typically reusable in other projects. However, if the PCB is designed with modularity in mind, some parts of the board may be reusable in similar projects.

Conclusion

PCBs and breadboards are both essential tools in electronic circuit design, each with its own advantages and disadvantages. PCBs offer durability, reliability, and compact designs, making them suitable for final products and mass production. On the other hand, breadboards provide flexibility, ease of use, and quick prototyping capabilities, making them ideal for experimentation and educational purposes.

When deciding between a PCB and a breadboard, consider factors such as the project’s complexity, purpose, and timeline. For permanent installations or high-volume production, PCBs are the preferred choice, while breadboards are more suitable for temporary setups, prototyping, and learning.

By understanding the differences between PCBs and breadboards and knowing when to use each one, you can streamline your Electronic design process and create circuits that meet your specific requirements.

No responses yet